Sulfuric acid pickling inhibitor and preparation method thereof

A sulfuric acid pickling and inhibitor technology, applied in the chemical industry, can solve the problems of yellow cracks and unclean pickling on the surface of the workpiece, and achieve the effects of reducing acid consumption, saving acid treatment costs, and reducing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

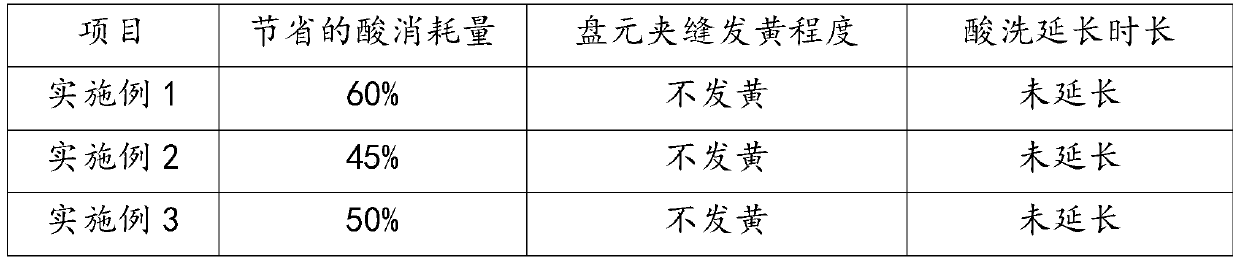

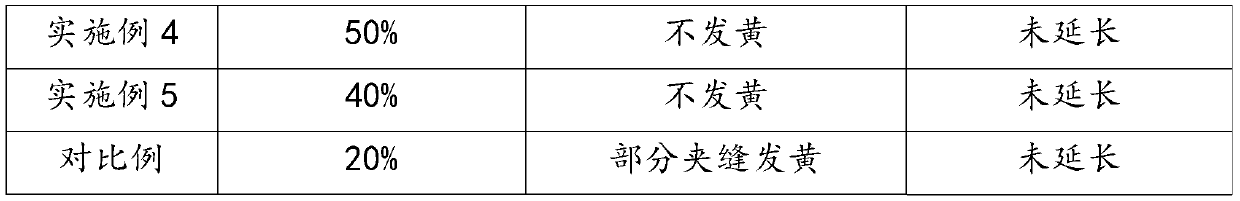

Examples

Embodiment 1

[0018] The preparation method of the sulfuric acid pickling inhibitor of the present embodiment comprises the following steps:

[0019] According to the mass percentage of raw materials, 20% of sodium chloride, 3% of potassium iodide, 1% of dioctyl sulfosuccinate sodium salt, 2% of fatty alcohol polyoxyethylene ether, and 74% of water are provided. First add a certain amount of water in the reaction kettle, then add sodium chloride and potassium iodide, stir well for 30 minutes, and get the premix after the sodium chloride and potassium iodide are dissolved; then add dioctyl sulfosuccinate sodium salt, fatty alcohol polyoxyethylene ether, fully stirred for 40 minutes, and stirred into a homogeneous solution to obtain a sulfuric acid pickling inhibitor.

Embodiment 2

[0021] The preparation method of the sulfuric acid pickling inhibitor of the present embodiment comprises the following steps:

[0022] According to the mass percentage of raw materials, 30% of sodium chloride, 1% of potassium iodide, 5% of dioctyl sulfosuccinate sodium salt, 0.1% of fatty alcohol polyoxyethylene ether, and 63.9% of water are provided. First add a certain amount of water in the reaction kettle, then add sodium chloride and potassium iodide, stir well for 20 minutes, and get the premix after the sodium chloride and potassium iodide are dissolved; then add dioctyl sulfosuccinate sodium salt, fatty alcohol polyoxyethylene ether, fully stirred for 30 minutes, and stirred into a homogeneous solution to obtain a sulfuric acid pickling inhibitor.

Embodiment 3

[0024] The preparation method of the sulfuric acid pickling inhibitor of the present embodiment comprises the following steps:

[0025] According to the mass percentage of raw materials, 5% of sodium chloride, 5% of potassium iodide, 5% of dioctyl sulfosuccinate sodium salt, 5% of fatty alcohol polyoxyethylene ether, and 80% of water are provided. First add a certain amount of water in the reaction kettle, then add sodium chloride and potassium iodide, stir well for 40 minutes, and get the premix after the sodium chloride and potassium iodide are dissolved; then add dioctyl sulfosuccinate sodium salt, fatty alcohol polyoxyethylene ether, fully stirred for 20 minutes, and stirred into a homogeneous solution to obtain a sulfuric acid pickling inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com