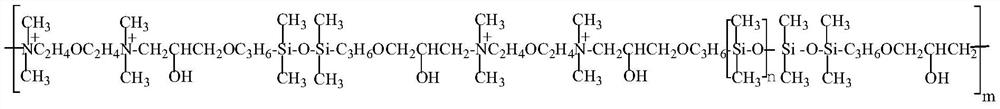

A kind of block quaternary ammonium group modified polysiloxane and preparation method thereof

A technology of polysiloxane and quaternary ammonium group, which is applied in the field of block quaternary ammonium group modified polysiloxane and its preparation, which can solve the problems of increased production cost, low boiling point of isopropanol, fabric shade, etc., and achieve soft performance improvement, amino The effect of content increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

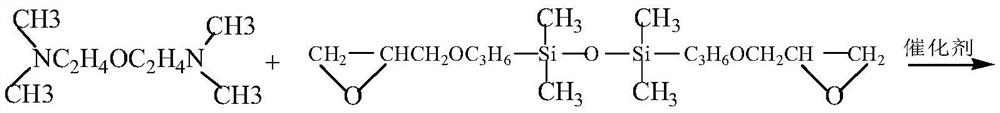

Method used

Image

Examples

Embodiment 1

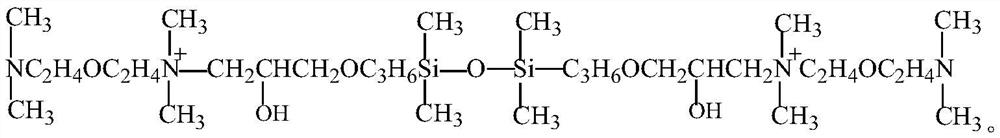

[0025] 1) Put 320g (2mol) of bis(2-dimethylaminoethyl) ether and 360g (1mol) of epoxy double head into the reaction flask with stirring and condensing device, then add 60g (1mol) of acetic acid, and start stirring , slowly raised the temperature to 95-100° C., kept the temperature for 4 hours, and then cooled to room temperature to obtain 740 g of tertiary amine-terminated silicon-containing polyether intermediate A.

[0026] 2) Weigh 148g (0.2mol) of the tertiary amino-terminated silicon-containing polyether intermediate A148g (0.2mol) prepared in the previous step, and 800g (0.2mol) of epoxy-terminated silicone oil with a molecular weight of 4000 (polymer n=50, solid content of 99.7%) , into a reaction flask equipped with a stirring and condensing device, then add 40 g (0.2 mol) of lauric acid, start stirring, slowly raise the temperature to 95-100 ° C, keep the temperature for 10 hours, cool to room temperature, and obtain 988 g of block quaternary ammonium modified Non-tox...

Embodiment 2

[0028] 1) Add 320g (2mol) of bis(2-dimethylaminoethyl) ether and 360g (1mol) of epoxy double head into the reaction flask with stirring and condensing device, then add 30g (0.5mol) of acetic acid and 100g (0.5mol) lauric acid, start stirring, slowly heat up to 100-105° C., keep warm for 5 hours, then cool to room temperature to obtain 810 g of tertiary amino-terminated silicon-containing polyether intermediate B.

[0029] 2) Weigh 1200 g (0.2 mol) of the tertiary amine-terminated silicon-containing polyether intermediate B162g (0.2 mol) prepared in the previous step, and 1200 g (0.2 mol) of epoxy-terminated silicone oil (polymer n=77, solid content 99.7%) with a molecular weight of 6000 ), added to a reaction flask with a stirring and condensing device, then added 12 g (0.2 mol) of acetic acid, started stirring, slowly raised the temperature to 95-100 ° C, kept the temperature for 12 hours, and cooled to room temperature to obtain 1374 g of block quaternary ammonium modified N...

Embodiment 3

[0031] 1) Add 320g (2mol) of bis(2-dimethylaminoethyl) ether and 360g (1mol) of epoxy double head into the reaction flask with stirring and condensing device, then add 36g (0.6mol) of acetic acid and 80g (0.4mol) lauric acid, start stirring, slowly heat up to 90-95°C, keep warm for 7 hours, cool to room temperature, and obtain 796g of tertiary amino-tertiary silicon-containing polyether intermediate C.

[0032] 2) Weigh 119.4g (0.15mol) of the tertiary amine-terminated silicon-containing polyether intermediate C119.4g (0.15mol) prepared in the previous step, and 1200g (0.15mol) of epoxy-terminated silicone oil (polymer n=104, solid content: 99.6%) with a molecular weight of 8000 mol), add it to the reaction flask with a stirring and condensing device, then add 4.5g (0.075mol) of acetic acid and 15g (0.075mol) of lauric acid, start stirring, slowly raise the temperature to 95-100°C, keep the temperature for 14 hours, and cool After reaching room temperature, 1338.9 g of block q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com