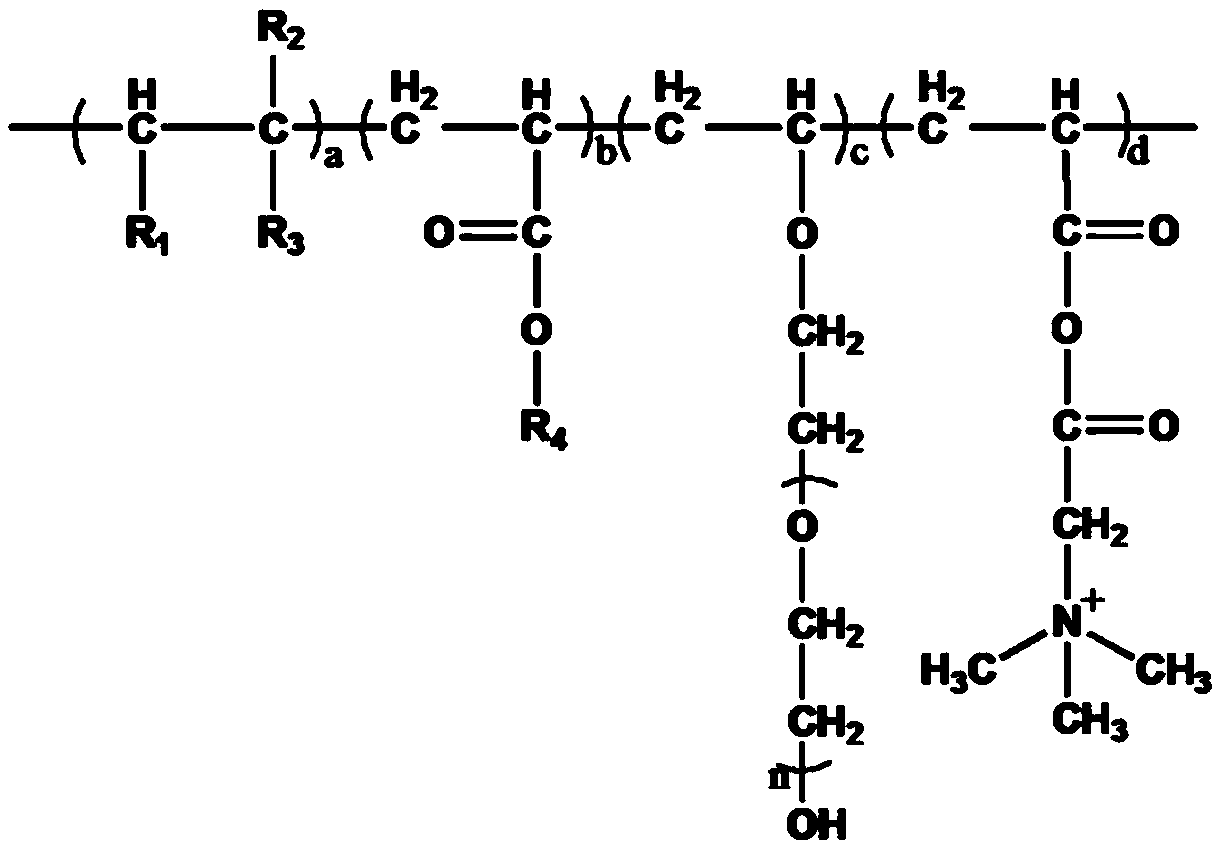

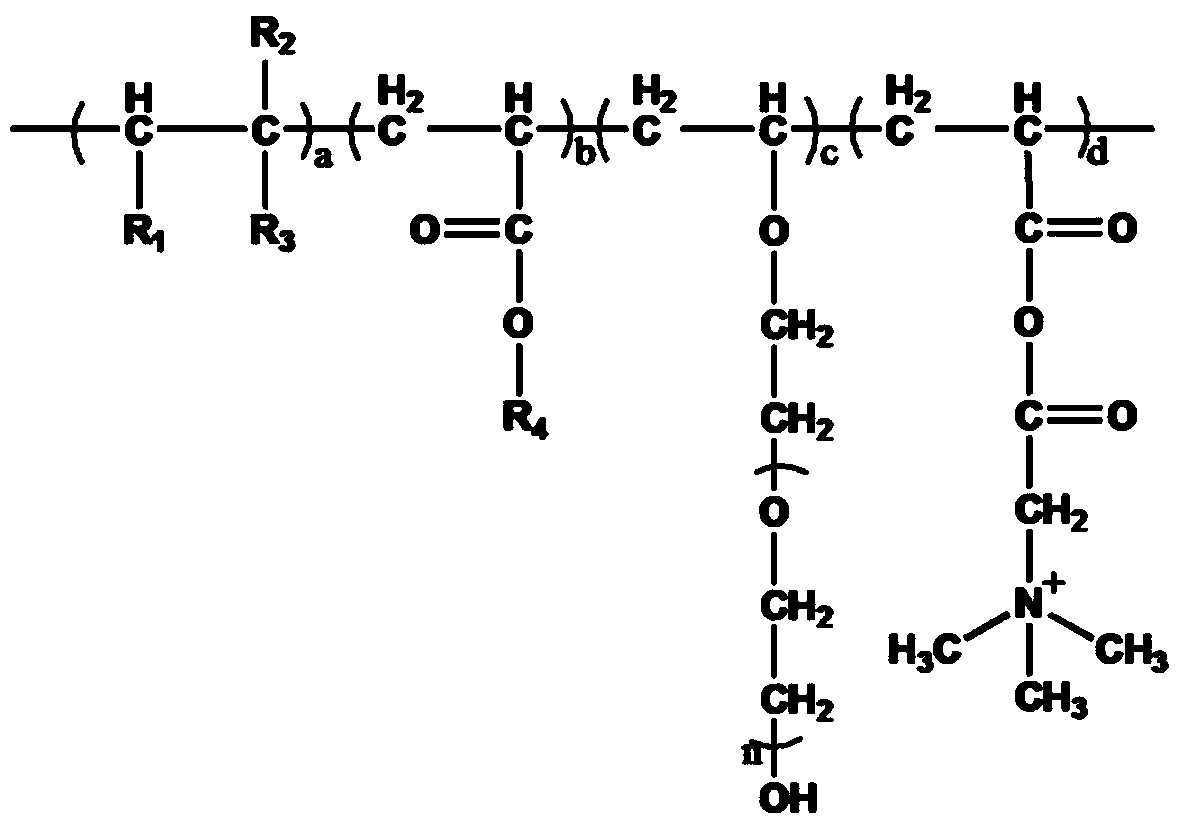

Polycarboxylate superplasticizer aiming at slow initial reaction of high-grade concrete and preparation method thereof

A concrete and high-grade technology, applied in the field of concrete admixtures, can solve the problems of increasing the workload of mixing plant personnel, prolonging the concrete production time, and affecting the normal construction of the construction site, so as to improve the viscosity of concrete, increase the water-reducing rate and retention , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

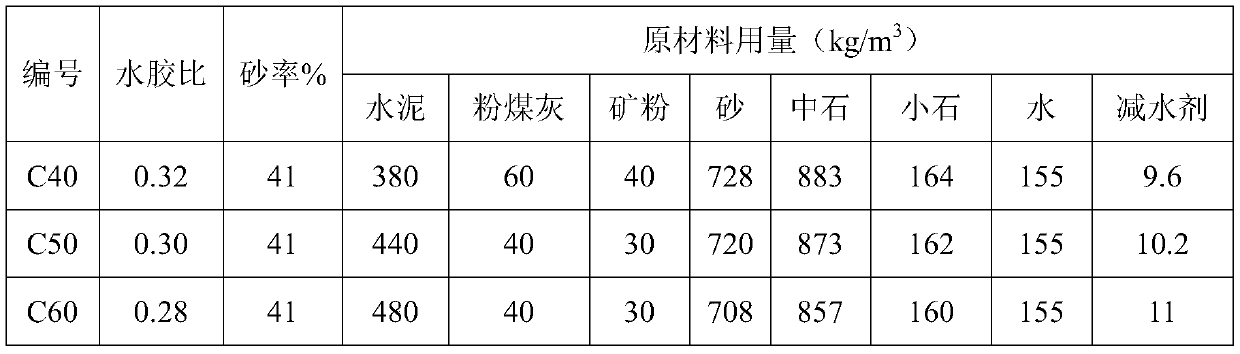

Embodiment 1

[0030] The polycarboxylate water-reducer and its preparation method aiming at the slow initial response of high-grade concrete according to the present invention comprise the following steps:

[0031] 1) Dissolve 100 g of betaine and 77 g of acryloyl chloride in 100 mL of DMF, react in an ice-water bath (0° C.) for 2 hours at a constant temperature, and remove the solvent to obtain modified betaine.

[0032] 2) Dissolve 100 g of glucose and 50 g of acryloyl chloride in 90 mL of DMF, react in an ice-water bath (0° C.) at a constant temperature for 2 h, and remove the solvent to obtain glucosyl acrylate.

[0033] 3) At room temperature, dissolve 260g of ethylene glycol monovinyl polyglycol ether, 22g of modified betaine, 5g of glucosyl acrylate, 20g of methacrylic acid, and 3.8g of potassium persulfate in 366g of deionized water to prepare A1 solution;

[0034] 4) Dissolve 20g of methacrylic acid and 3.2g of mercaptoethanol in 60g of deionized water to prepare B1 solution;

[...

Embodiment 2

[0038] The polycarboxylate water-reducer and its preparation method aiming at the slow initial response of high-grade concrete according to the present invention comprise the following steps:

[0039] 1) Dissolve 100 g of citric acid and 47 g of acryloyl chloride in 90 mL of DMF, react in an ice-water bath (0° C.) at a constant temperature for 2 h, and remove the solvent to obtain citric acid acrylate.

[0040] 2) At room temperature, dissolve 260g ethylene glycol monovinyl polyglycol ether, 5g modified betaine, 30g citric acid acrylate, 20g fumaric acid, 0.7g hydrogen persulfide, 2.0g ammonium persulfate in 384g deionized water, configured as A2 solution;

[0041] 3) Dissolve 20g of acrylic acid and 3.2g of mercaptoacetic acid in 60g of deionized water to form B2 solution;

[0042] 4) Dissolve 1.5g vitamin C in 70g deionized water to prepare C2 solution;

[0043] 5) Add B2 and C2 to the A2 solution at a constant speed, the time for B2 to be added is 2 hours, and the time fo...

Embodiment 3

[0045] The polycarboxylate water-reducer and its preparation method aiming at the slow initial response of high-grade concrete according to the present invention comprise the following steps:

[0046]1) Dissolve 100 g of molasses and 50 g of acryloyl chloride in 90 mL of DMF, react in an ice-water bath (0° C.) at a constant temperature for 2 h, and remove the solvent to obtain molasses acrylate.

[0047] 2) At room temperature, 260g ethylene glycol monovinyl polyglycol ether, 18g modified betaine, 24g molasses acrylate, 20g 2-acrylamide-2-methylpropanesulfonic acid, 3.6g ammonium persulfate, Dissolve in 395g deionized water to make A3 solution;

[0048] 3) Dissolve 20g of methacrylic acid and 3.2g of mercaptopropionic acid in 60g of deionized water to form B3 solution;

[0049] 4) Dissolve 1.5g E51 in 70g deionized water to prepare C3 solution;

[0050] 5) Add B3 and C3 to the A2 solution at a constant speed, the time for B2 to be added is 2 hours, and the time for C2 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com