Full-automatic unmanned aerial vehicle service desk for electric power inspection and using method

A technology of power inspection and unmanned aerial vehicles, applied in the field of unmanned aerial vehicles and electric power inspection and maintenance, can solve the problems that the model cannot be practically applied to actual operation occasions, cannot realize the full automatic operation of the system, and cannot get rid of the shackles of human resources, etc. Achieve the effect of improving wireless charging efficiency, perfecting drone inspection system, and facilitating analysis and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

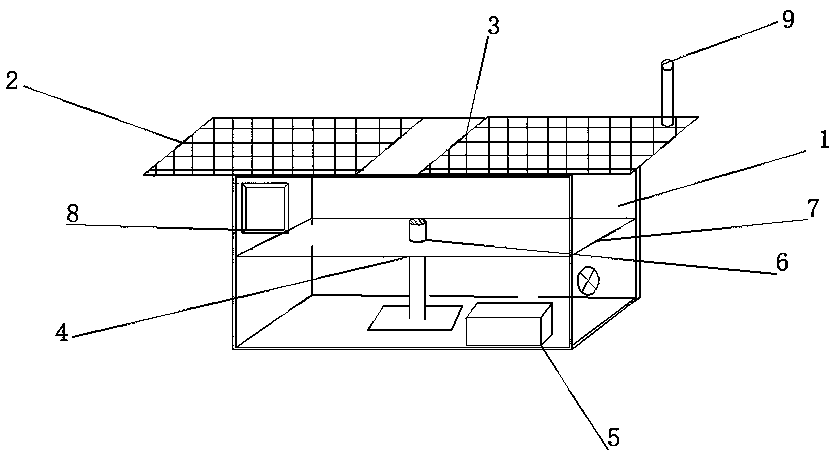

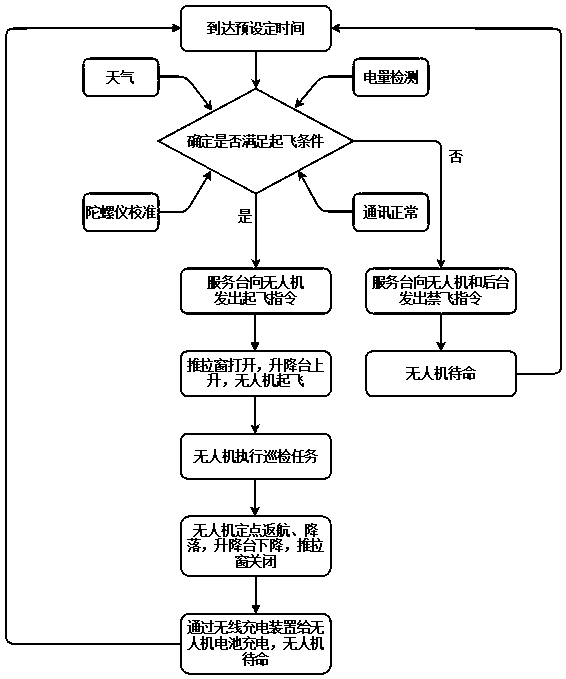

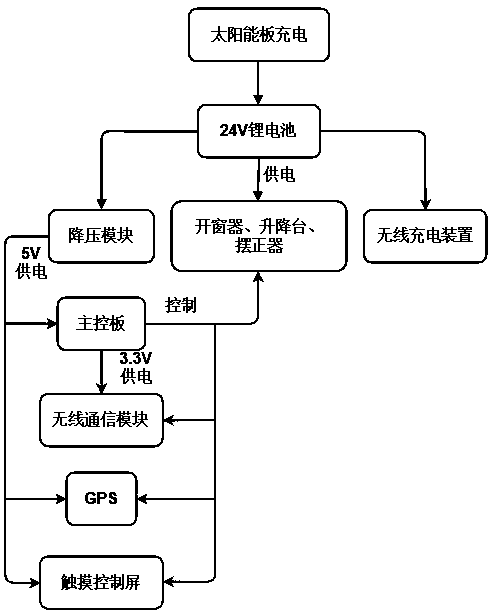

[0043] The fully automatic UAV service desk obtains the current location information and time through the built-in GPS module. When the system reaches the set time, the communication module judges according to the weather conditions and the power of the UAV provided by the background management system. Is it possible to fly the mission. When conditions are met, the skylight 3 structure of the service desk is opened, and the lifting platform 4 is raised. The UAV received the take-off command and began to perform power inspection tasks. After the unmanned aerial vehicle flies out, the lifting platform 4 descends to the starting position again, and the skylight 3 is closed, waiting for the unmanned aerial vehicle to return. After receiving the UAV return command, the service desk opens the skylight 3 again, the lifting platform 4 is stretched out, and the UAV docks at a fixed point and returns to the starting position. The service desk is equipped with a wireless charging devic...

Embodiment 2

[0046] The second embodiment proposes the technical solution of the wireless charging and the wireless charging aligner 7 device adopted by the service station.

[0047] At present, the charging forms of aircraft charging piles invented to solve the poor endurance of aircraft on the market are divided into wired charging and wireless charging. In this solution, the charging device set up in the service desk is wireless charging. The UAV is docked on the lifting platform 4 at a fixed point. Due to certain errors in GPS positioning, it is difficult to achieve very accurate positioning. Therefore, a mechanical device of a squarer 7 is set up in the service desk. The push rods of the stabilizer 7 surround and form the landing area of the aircraft, and the push rods of the stabilizer 7 are driven by the drive unit to reduce the landing area. When the unmanned aerial vehicle parked in the landing area described in the lifting platform 4 is moved to the rechargeable range of the w...

Embodiment 3

[0049] The third embodiment proposes the communication module of the fully automatic drone service desk to realize the tripartite communication technical scheme of the service desk, the drone and the background management system.

[0050] At present, most of the power inspection drones use drones equipped with high-definition cameras and infrared thermal imagers to take pictures of the lines, and manually analyze the videos and photos to identify the main defects and hidden dangers.

[0051] In this solution, the three-party communication between the UAV and the background management system can be realized through the communication module in the service desk. When performing line inspection tasks remotely, the service desk can also be used as a relay communication station to transmit image data information, and the host computer in the background completes subsequent image data recognition and analysis, ensuring image quality without increasing the number of drones equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com