A kind of sizing equipment for foam rubber sealing strip

A foamed rubber and sealing strip technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of easy deformation, no shrinkage, affecting the use of sealing strips, etc., to improve product quality and practicability, Guarantee the bonding performance and improve the effect of sizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

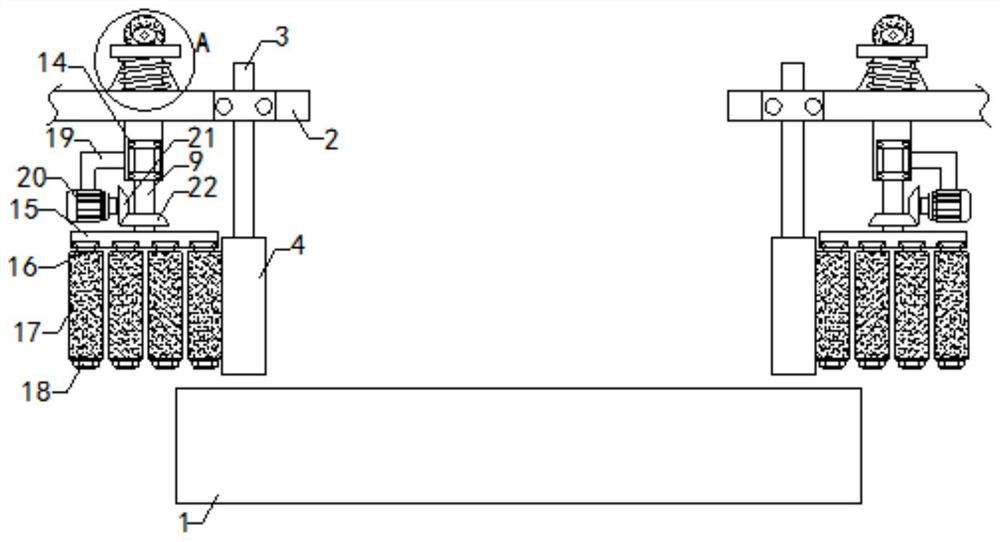

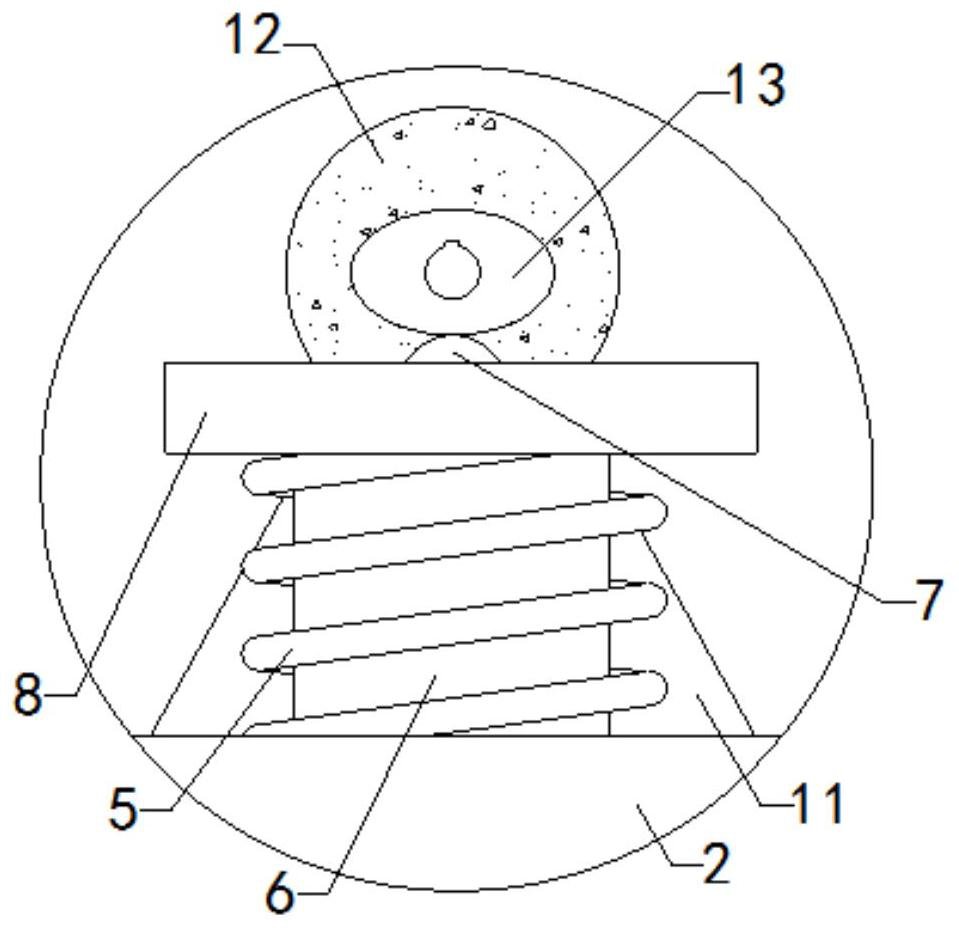

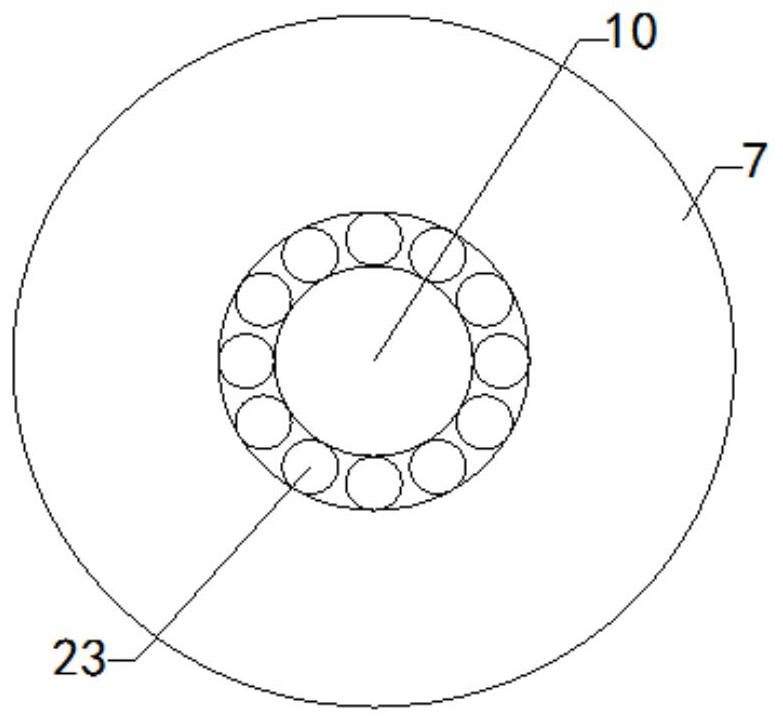

[0020] A sizing device for foam rubber sealing strips, including a conveyor belt, a glue injector, a scraper, a guiding mechanism, and a cleaning mechanism. Its structure is as follows: figure 1 shown. The conveyor belt is used to transport the sealing strip to be glued. The glue injector is located above the conveyor belt and is used to apply glue to the sealing strip on the conveyor belt; the leveler is located above the conveyor belt and is used to scrape the glue on the sealing strip; The top is used to guide the sealing strip; the cleaning mechanism is located outside the guiding mechanism and is used to clean the glue on the guiding mechanism. In the present invention, the guiding mechanism includes two groups, and the two groups of guiding mechanisms are arranged symmetrically above the left and right sides of the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com