Corner cutting die capable of adjusting corner cutting angle

A technology of cutting angles and angles, applied in metal processing equipment, perforating tools, manufacturing tools, etc., can solve the problems of reducing production efficiency, increasing production investment capital costs, and shortening the service life of molds, so as to ensure and improve processing quality and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

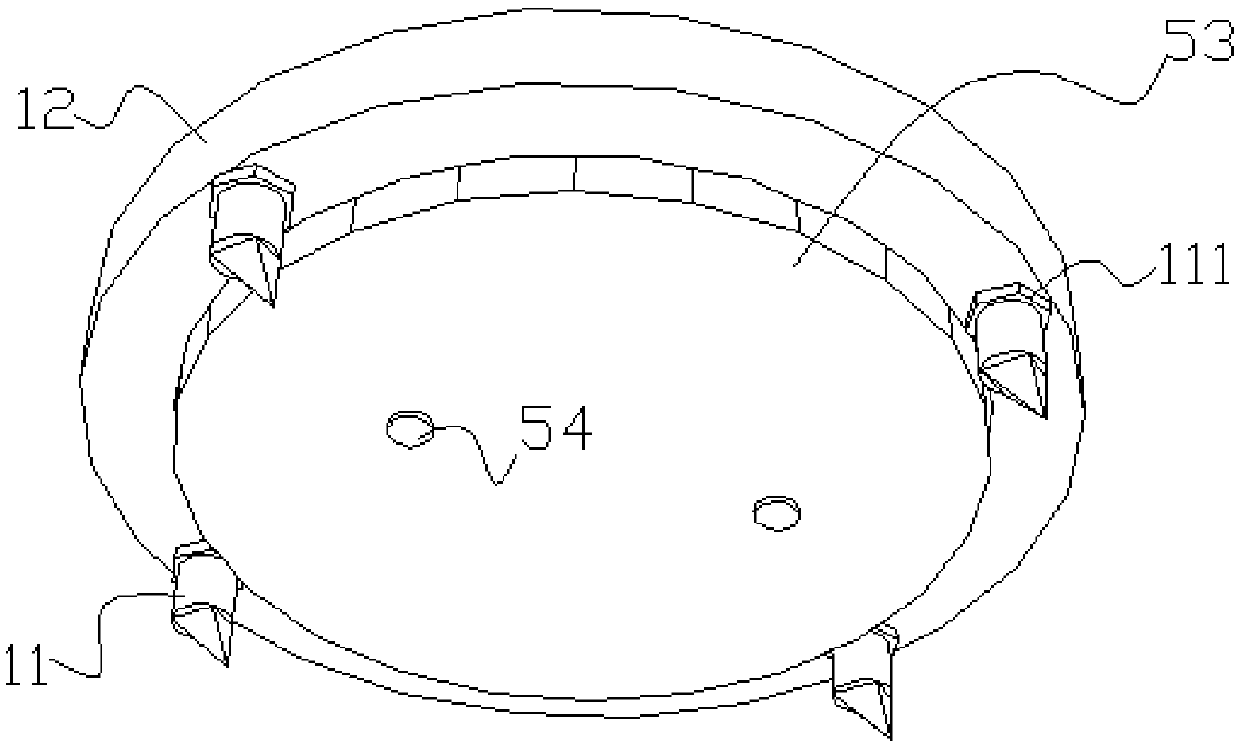

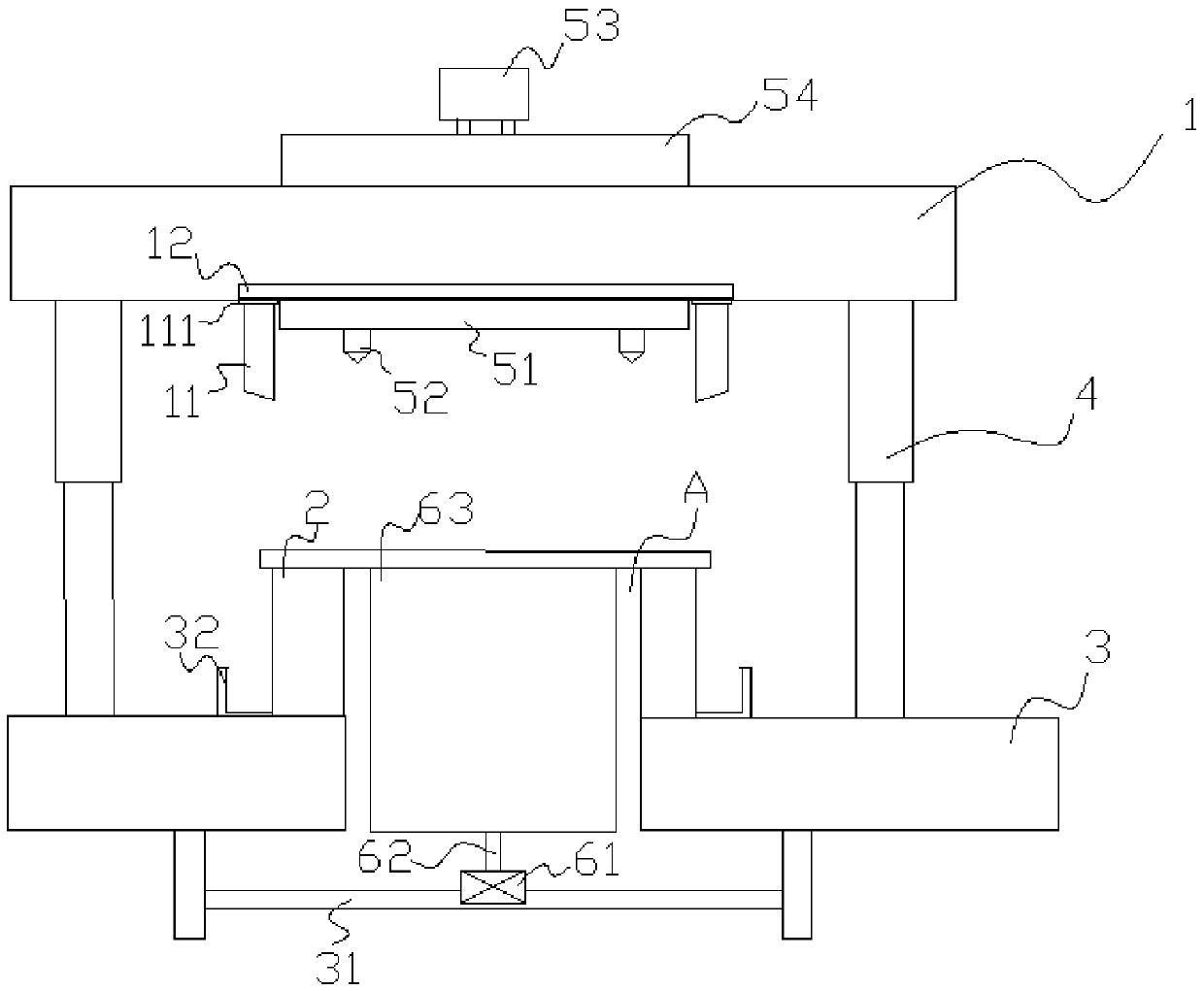

[0024] see figure 1 with figure 2 , a corner-cutting die that can adjust the corner-cutting angle, including a corner-cutting upper die 1, a corner-cutting lower die 2, a base 3, a guide rod 4, a corner-cutting tool 11, a rotating disk 12, a fixed plate 51, a punching tool 52 and Punching die. The base 3 is located directly below the corner-cutting upper die 1 and is connected to the corner-cutting upper die 1 through a guide column 4 . The guide column 4 includes a guide sleeve connected with the corner cutting upper die 1 and a guide column connected with the base 3 . The base 3 is provided with a corner-cutting lower die.

[0025] The turntable 12 is a ring structure, and is positioned at the bottom of the angle-cutting upper die 1 , and its lower end is connected with a corner-cutting tool 11 . The fixing plate 51 is fixed on the middle part of the turntable 12 , and a punching tool 52 is disposed on the lower end thereof.

[0026] The base 3 is provided with a punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com