A kind of beneficiation system and beneficiation method of sulfide ore

A beneficiation method and sulfide ore technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of flotation agent consumption, high energy consumption of grinding, wear and tear, etc., to improve system processing capacity, The effect of shortening the sorting process and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

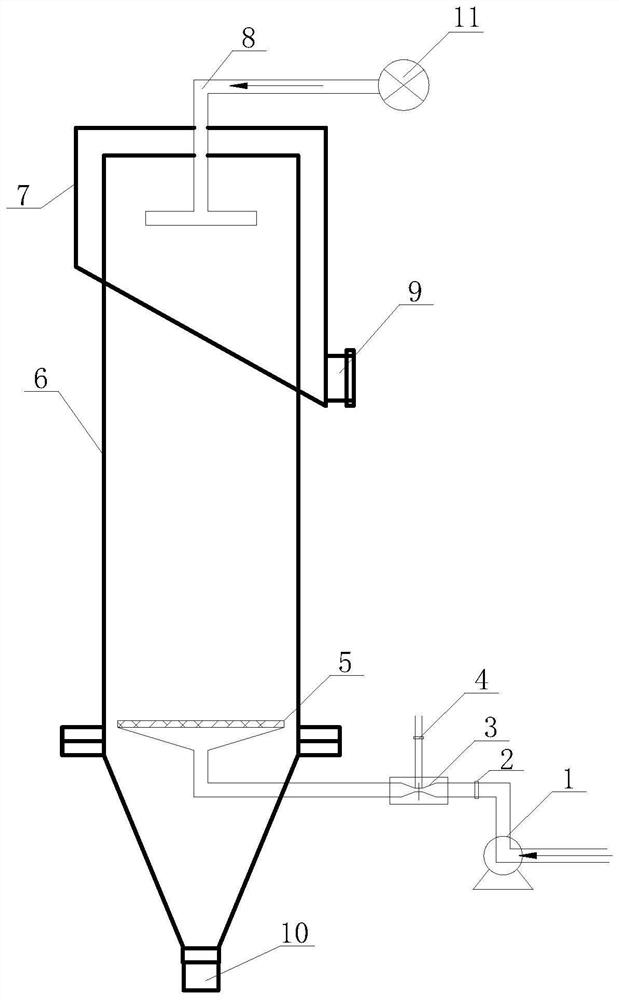

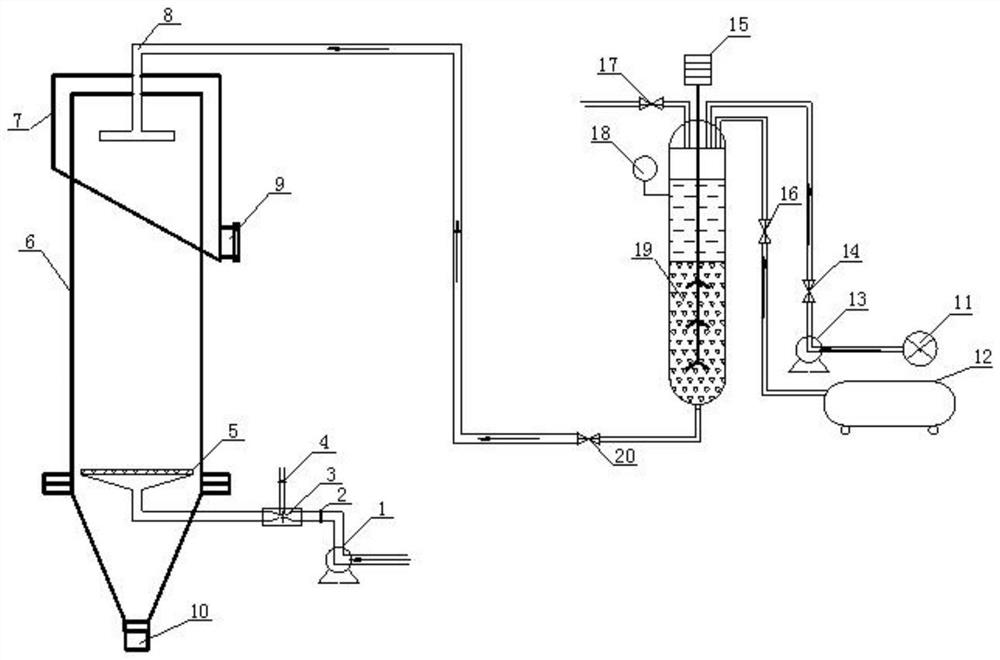

[0038] A specific embodiment of the present invention, such as figure 1 with 3As shown, a kind of beneficiation system of sulfide ore is disclosed, and a ball mill, a spiral classifier, a mixing tank 11, a coarse particle separation device and a flotation machine are arranged along the beneficiation pipeline; the coarse particle separation device includes a first cylinder 6 , the second cylinder 7 and the gas-water mixing input device, the first cylinder 6 and the second cylinder 7 are cylindrical structures, the second cylinder 7 is nested outside the upper end of the first cylinder 6, and the second The upper end surface of the cylinder 7 is higher than the upper end surface of the first cylinder 6, and the side of the second cylinder 7 is provided with an ore discharge port 9, and the material in the first cylinder 6 can overflow into the second cylinder 7, It is discharged through the ore discharge port 9.

[0039] Compared with the prior art, the beneficiation system of...

Embodiment 2

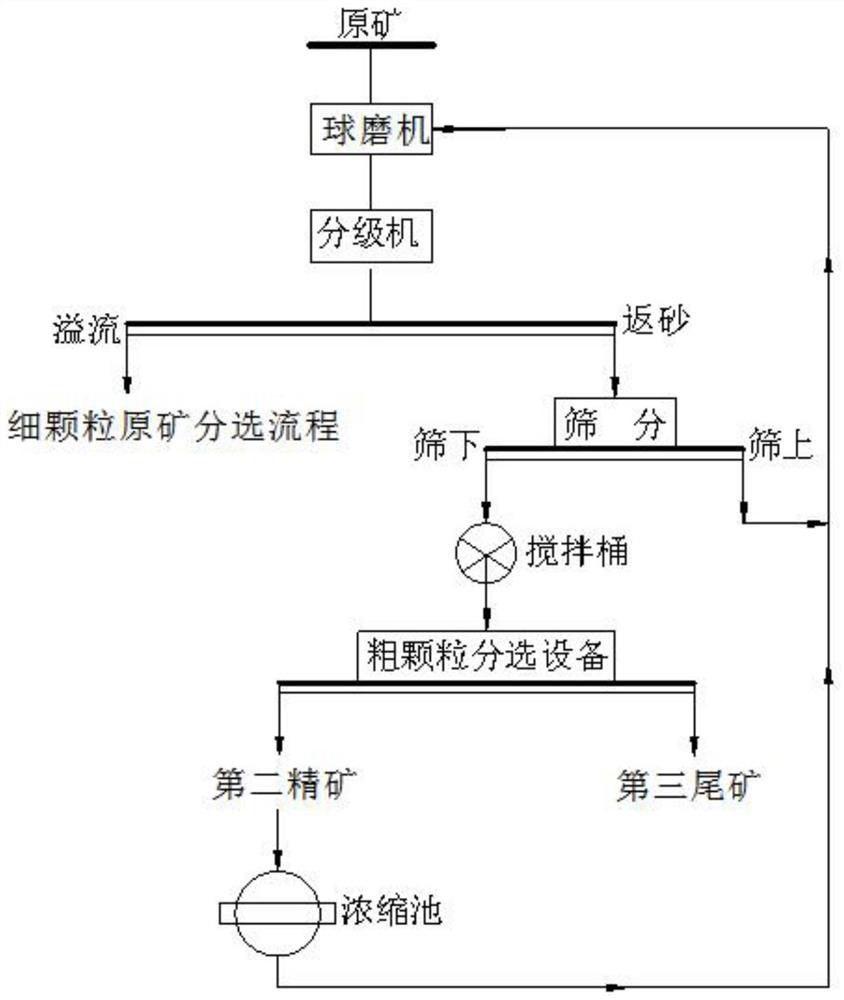

[0063] A specific embodiment of the present invention, such as figure 2 As shown, a kind of beneficiation method of sulfide ore is disclosed, adopt the beneficiation system of the sulfide ore provided by embodiment 1, the beneficiation method comprises the following steps:

[0064]Step S1: After the raw sulfide ore is ground by a ball mill, it is introduced into a spiral classifier for classification, and after classification, fine-grained raw ore with overflow and coarse-grained raw ore with returned sand are obtained;

[0065] Step S2: After the coarse-grain raw ore is screened, the material on the screen is returned to the ball mill, and the material under the screen enters the mixing tank 11, and the pulp is adjusted in the mixing tank 11 to obtain the ore pulp; the fine-grain raw ore is subjected to a rough grinding and a rough selection. The coarse concentrate and rough tailings are obtained; the coarse concentrate is regrinded once more, three times of beneficiation, a...

Embodiment 3

[0091] In a specific embodiment of the present invention, the mineral processing method provided in Example 2 is used to obtain the fine particle raw ore overflowed by a spiral classifier of a certain molybdenite (molybdenum grade is 0.076%) after a rough grinding and a rough selection Coarse concentrate and rough tailings; the coarse concentrate is regrinded once, three times of beneficiation, and two fine sweeps to obtain the first concentrate and the first tailings; the coarse tailings are swept three times to obtain the second tailings (see attached for specific process flow figure 2 with 4 , the process parameters are shown in the following table 1); the coarse particle raw ore that returns to the sand is screened, the sieve hole size is 2.0mm, the +2.00mm particle size material returns to the ball mill, and the -2.00mm sieved material enters the mixing tank, specifically including the following steps :

[0092] Step 1: Import the -2.00mm under-sieve material into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com