Low-temperature fermented beef sausage and preparation method thereof

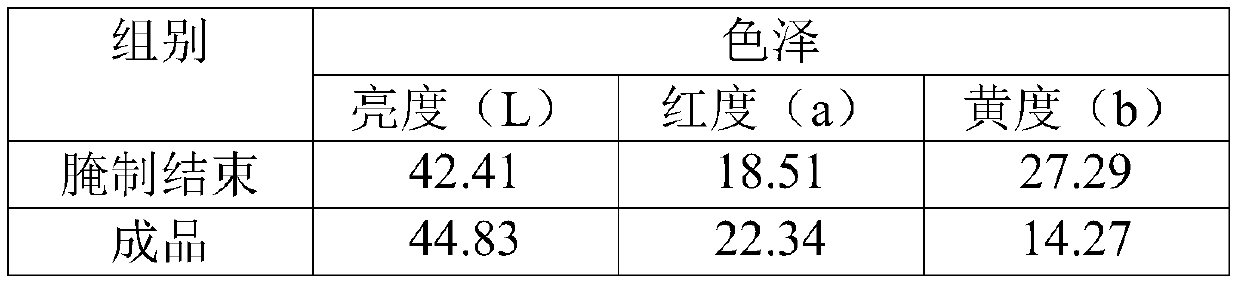

A technology of low-temperature fermentation and beef sausage, which is applied in food science and other fields, can solve the problems of poor sausage storage, harm to human health, and insufficient beef sausage, and achieve the effects of reducing residual nitrous acid, improving color, and improving the composition of flavor substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-temperature fermented beef sausage, comprising the following components in parts by weight: 1% of edible salt, 6% of white sugar, 1% of rice wine, 0.05% of chili powder, 0.1% of thirteen spice powder, 0.2% of tomato powder, and 0.5% of starter %, the balance is lean beef and diced fat.

Embodiment 2

[0024] A low-temperature fermented beef sausage, comprising the following components in parts by weight: 3% edible salt, 2% white sugar, 3% rice wine, 0.2% chili powder, 0.3% thirteen spice powder, 1% tomato powder, 3% fermented agent, the balance is lean beef and diced fat.

Embodiment 3

[0026] A low-temperature fermented beef sausage, comprising the following components in parts by weight: 2.0% of edible salt, 4% of white sugar, 1.5% of rice wine, 0.1% of chili powder, 0.15% of thirteen spice powder, 0.5% of tomato powder, and 0.5% of Leavening agent, the balance is lean beef and diced fat. The starter is a 1:2 compound of Lactobacillus sake and Staphylococcus xylosus.

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] S1. Mix the minced lean beef with diced fat (blanched) at a ratio of 4:1, mix with other materials, marinate at 4°C for 12-15 hours, and pour into collagen casings with a diameter of 22-25mm Medium; among them, lean beef: selected beef hind legs (fascia removed); pig fat is cut into 0.4×0.4×0.4 fat cubes, blanched in 45-60°C water for 10 minutes, and then taken out;

[0029] S2. Fermentation: ferment for 24 hours at a temperature of 28°C and a humidity of 90%, and the acidity drops to 4.6-5.0;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com