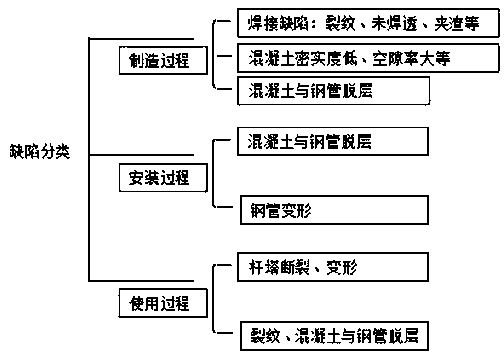

Qualitative and quantitative defect detection method for thin-walled centrifugal concrete steel tube tower

A quantitative detection method, the technology of concrete steel pipes, applied in the direction of measuring devices, material inspection products, test and manufacturing objects, etc., to achieve the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

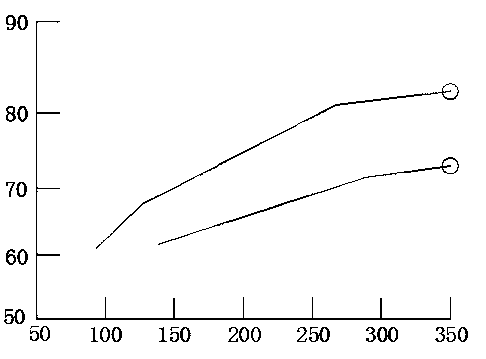

[0035]Embodiment 1, bonding state ultrasonic detection

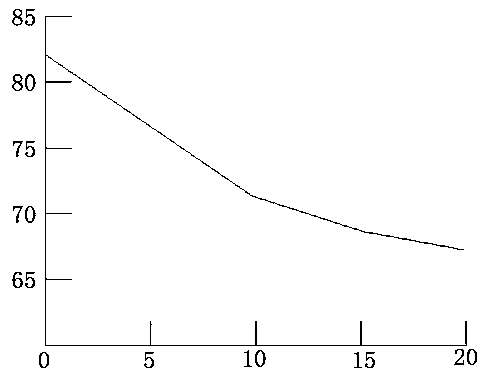

[0036] Ultrasonic testing principle: When the ultrasonic wave is perpendicular to the smooth plane surface, a reflected wave opposite to the direction of the incident wave will be generated in the first medium, and a transmitted wave in the same direction as the incident wave will be generated in the second medium.

[0037] Let the sound pressure of the incident wave be P 0 (sound intensity is I 0 ), the voltage of the reflected wave is P r (sound intensity is I r ), the sound pressure of the transmitted wave is P t (sound intensity is I t ).

[0038] The sound pressure P of the reflected wave and the sound pressure P of the incident wave on the interface 0 The ratio is called the sound pressure reflectivity of the interface, expressed by r, that is, r=P r / P 0 .

[0039] Transmitted wave sound pressure P on the interface t and incident wave sound pressure P 0 The ratio is called the sound pressure transmitta...

Embodiment 2

[0090] Embodiment 2 welding reinforcement scheme

[0091] The reinforcement method of welding reinforcement plates on the weld seam is more suitable for the thin-walled centrifugal concrete steel pipe structure studied by the present invention. While meeting the strength requirements, it can simplify the difficulty of field operations and improve work efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com