A hand-held mixer for floor tile joints

A technology of mixer and beautiful seam, which is applied in the direction of construction and building construction, and can solve the problems of slow mixing speed and accelerated oxidation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

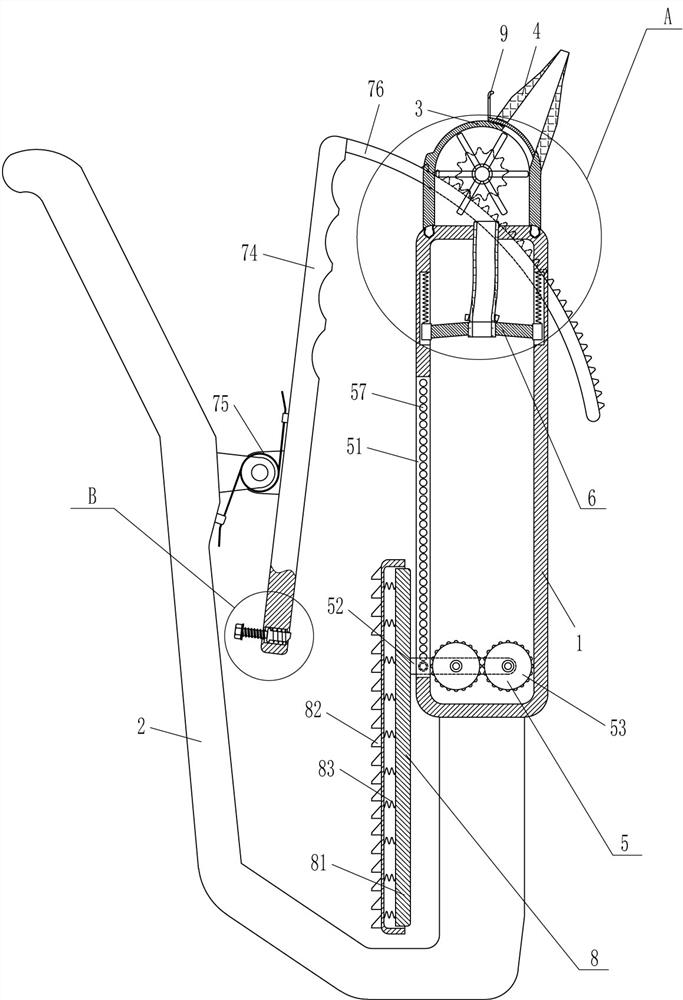

[0023] A hand-held mixer for floor tile beauty seams, such as Figure 1-4 As shown, it includes a frame 1, a handle 2, a mixing barrel 3, a glue nozzle 4, an extruding device 5, a fastening device 6 and a mixing device 7. The lower end of the frame 1 is equipped with a handle 2, and the front and rear sides of the frame 1 are Both are open, the upper end of the frame 1 is detachably installed with a mixing tube 3, the upper part of the mixing tube 3 is sealed with a glue nozzle 4, the glue nozzle 4 communicates with the mixing tube 3, the frame 1 is provided with an extruding device 5 for extruding raw materials at the bottom, a fastening device 6 for fixing aluminum tubes is provided at the top of the frame 1 , and the mixing tube 3 is provided with an epoxy resin, pigment and curing agent. Mixing device7.

[0024] The extrusion device 5 includes an n-type frame 52, an extrusion roller 53, a bump 55 and a first spring 56. A slot 51 is formed on the left side of the frame 1, ...

Embodiment 2

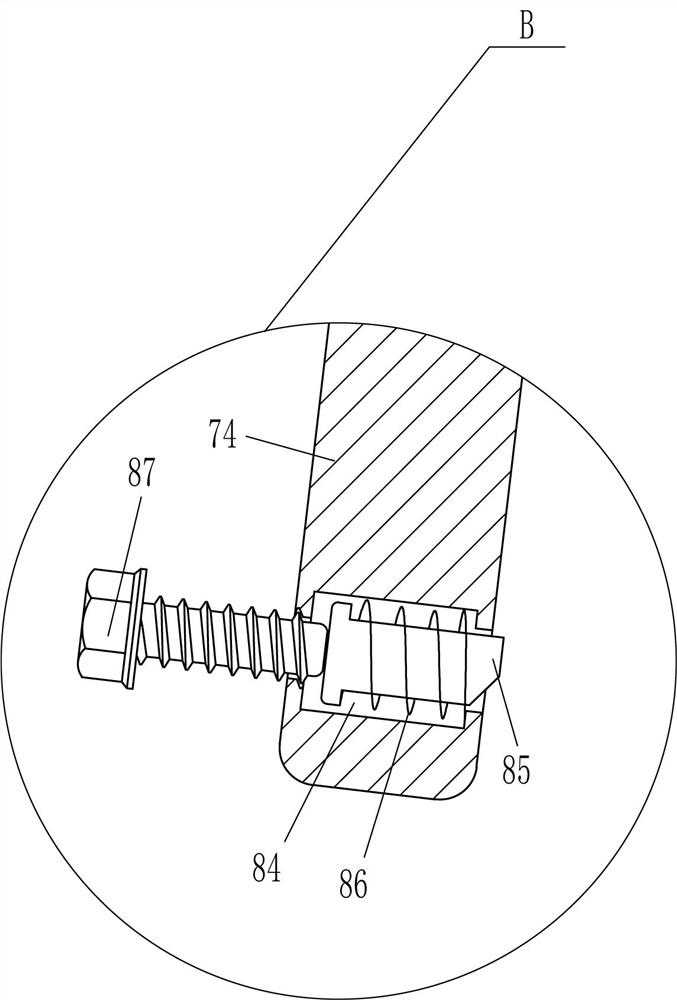

[0029] On the basis of Example 1, such as figure 1 and Figure 5 Shown, also include propulsion device 8, this propulsion device 8 includes fixed plate 81, movable rack 82, the 3rd spring 83, cooperate rod 85, the 4th spring 86 and bolt 87, this n-type frame 52 left side welding A fixed plate 81 is installed, the fixed plate 81 is provided with a movable rack 82 in a sliding manner, a third spring 83 is evenly spaced between the fixed plate 81 and the movable rack 82, and the lower end of the swing rod 74 Open hole 84 is arranged, and this hole 84 is provided with the mating bar 85 that matches with this movable rack 82, is connected with the 4th spring 86 between this mating bar 85 and this hole 84, and this swing bar 74 rotates up There is a bolt 87 which contacts and fits with the left end of the matching rod 85 .

[0030]After the epoxy resin, pigment and curing agent in the mixing cylinder 3 are used up, the operator rotates the bolt 87 clockwise, and the bolt 87 can ma...

Embodiment 3

[0032] On the basis of Example 2, such as figure 1 , image 3 and Figure 4 As shown, it also includes an arc-shaped baffle 9, which is provided with an arc-shaped baffle 9 in a sliding manner on the glue outlet 4, and the arc-shaped baffle 9 is closed and matched with the glue outlet 4, and the arc-shaped baffle The plate 9 is made of magnetic material, and the mixing cylinder 3 is made of iron.

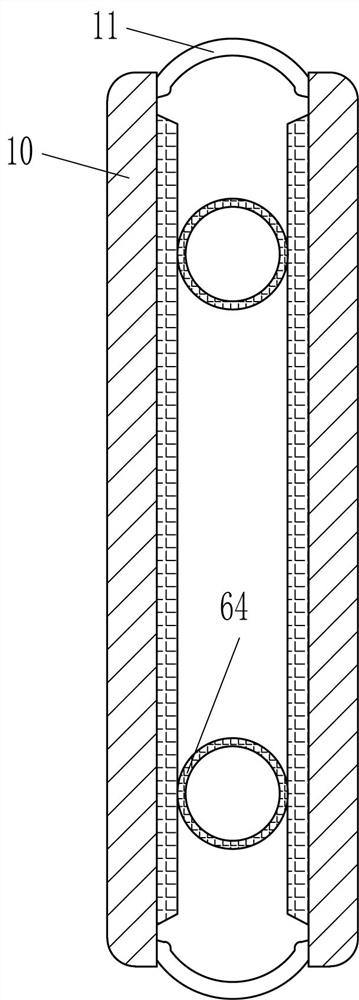

[0033] It also includes a pressing block 10 and a reed 11 , the hose 64 is provided with a pressing block 10 on the left and right sides, a reed 11 is connected between the two pressing blocks 10 , and the pressing block 10 is in contact with the hose 64 .

[0034] When mixing materials, the glue nozzle 4 is blocked by the arc-shaped baffle 9, so that the operator can mix epoxy resin, pigment and curing agent without turning the glue nozzle 4 upward. The arc-shaped baffle 9 is pulled out to adjust the discharge flow rate of the beautifying agent, and the magnetic arc-shaped baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com