A composite cementitious material for bonding high-voltage electric porcelain and its preparation method

A technology of composite cementitious material and high-voltage electric porcelain, applied in the field of electric porcelain, can solve the problems of reduced structural density, poor water resistance, increased porosity, etc., and achieves the effects of improving strength, water resistance and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

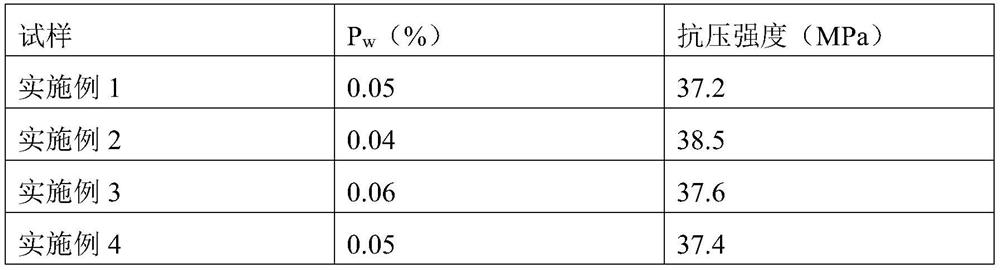

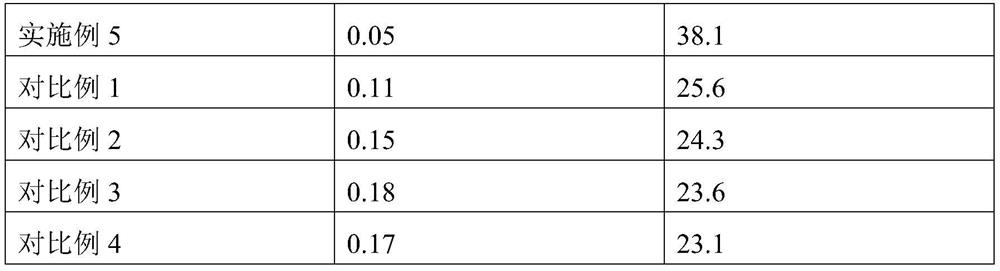

Examples

Embodiment 1

[0024] A composite cementitious material for bonding high-voltage electric porcelain, including the following raw materials in parts by weight: 60 parts of cement, 5 parts of quartz sand, 1 part of water reducer, 5 parts of nano oxides, 1 part of mineral fiber, and 3 parts of heterocyclics compound, 5 organic solvents and 20 parts of water.

[0025] In this embodiment, the mineral fiber is carbon fiber; the nano oxide is nano silicon dioxide; the heterocyclic compound is pyrrole; the organic solvent is ethanol, and the water reducing agent is sodium lignosulfonate.

[0026] A method for preparing a composite cementitious material for bonding high-voltage electric porcelain, comprising the following steps:

[0027] Step 1: Grind cement, quartz sand and mineral fiber separately, and then mix the ground raw materials evenly to obtain the first mixture;

[0028] The second step: then add nano-oxide, water reducer and water to the first mixture obtained in the first step, and stir...

Embodiment 2

[0036] A composite cementitious material for bonding high-voltage electric porcelain, including the following raw materials in parts by weight: 70 parts of cement, 7 parts of quartz sand, 2 parts of water reducing agent, 6 parts of nano oxides, 5 parts of mineral fibers, and 6 parts of heterocyclics compound, 7 parts organic solvent and 30 parts water.

[0037] In this embodiment, the mineral fiber is glass fiber; the nano oxide is nano magnesium oxide; the heterocyclic compound is pyrimidine; the organic solvent is ethanol, and the water reducing agent is sodium lignosulfonate.

[0038] A method for preparing a composite cementitious material for bonding high-voltage electric porcelain, comprising the following steps:

[0039] Step 1: Grind cement, quartz sand and mineral fiber separately, and then mix the ground raw materials evenly to obtain the first mixture;

[0040] The second step: then add nano-oxide, water reducer and water to the first mixture obtained in the first ...

Embodiment 3

[0048] A composite cementitious material for bonding high-voltage electric porcelain, characterized in that it includes the following raw materials in parts by weight: 80 parts of cement, 10 parts of quartz sand, 3 parts of water reducer, 10 parts of nano oxides, 10 parts of mineral fiber, 10 parts of Parts of heterocyclic compounds, 10 parts of organic solvent and 40 parts of water.

[0049] In this embodiment, the mineral fiber is carbon fiber; the nano-oxide is nano-alumina; the heterocyclic compound is imidazole; the organic solvent is acetone, and the water reducer is sodium lignosulfonate.

[0050] A method for preparing a composite cementitious material for bonding high-voltage electric porcelain, comprising the following steps:

[0051] Step 1: Grind cement, quartz sand and mineral fiber separately, and then mix the ground raw materials evenly to obtain the first mixture;

[0052] The second step: then add nano-oxide, water reducer and water to the first mixture obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com