Multifunctional planer tool for processing wood product

A multi-functional wood product technology, applied in the field of wood processing, can solve the problems of increasing the workload of workers, achieve the effect of convenient replacement and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

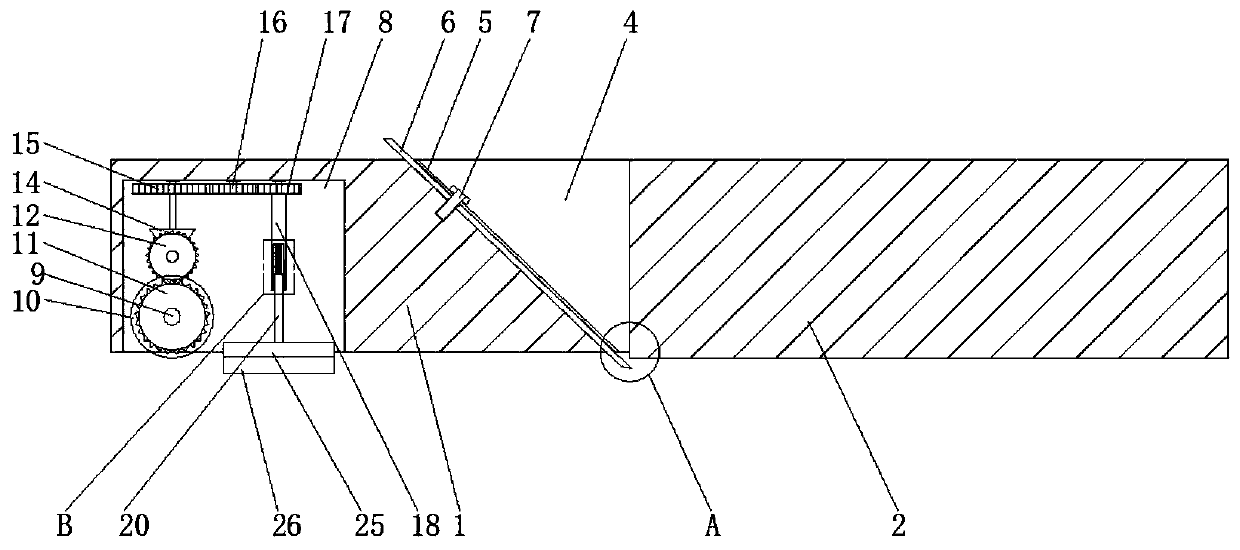

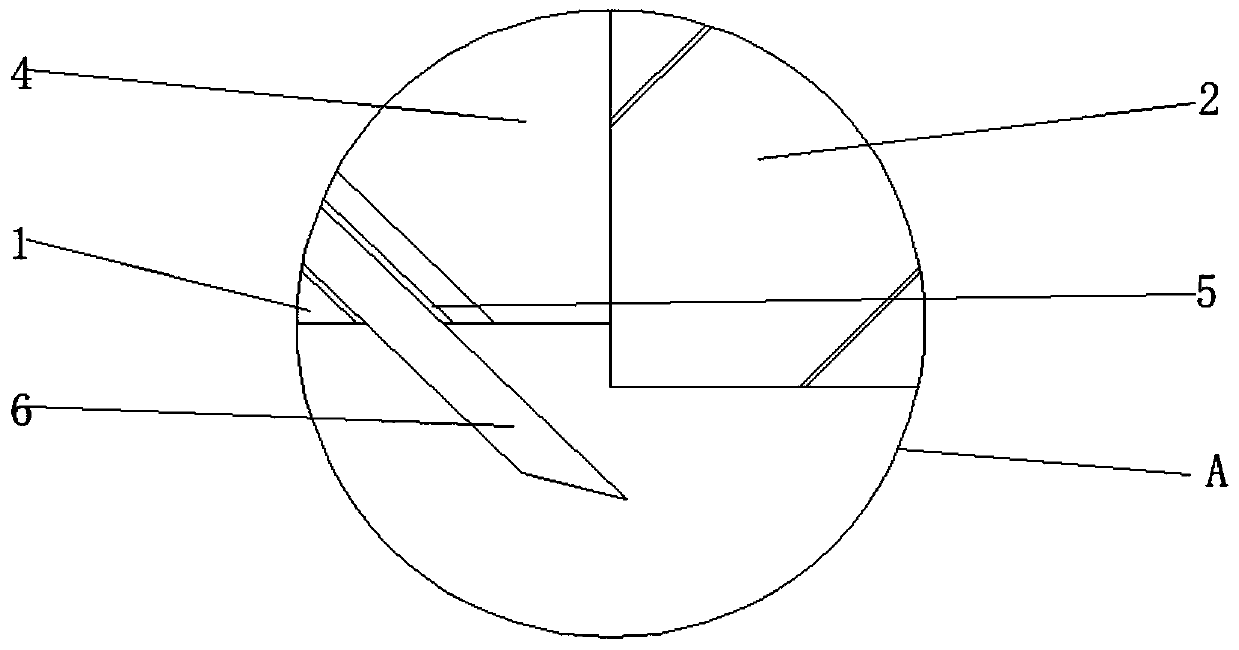

[0022] Such as Figure 1-3 A multifunctional planer for processing wood products is shown, comprising a rear plate 1 and a front plate 2 integrally formed with it, the level of the bottom surface of the rear plate 1 is lower than that of the bottom surface of the front plate 2, and the rear plate 1 A groove 4 that is connected to the upper and lower ends and has a right-angled trapezoidal structure is provided at the connection between it and the front plate 2, and the inclined surface of the groove 4 is provided with a blade 6 parallel to it. Both sides are provided with the chute 5 that slides at both ends of the blade 6, through the setting of sliding between the blade 6 and the chute 5 and the screw-type fixed connection mode, while providing convenience for the replacement of the blade 6, it also makes the two ends of the blade 6 The chute 5 on the side partially offsets the force on the blade, so as to reduce the damage to the blade due to the large force when the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com