Method for preparation, characterization and performance test of graphene-graphene nanoribbon sponge

A graphene nanoribbon and graphene technology, applied in the field of chemistry, can solve the problem that sponges do not have compressive elasticity, and achieve the effects of good compressive elasticity, simple operation and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

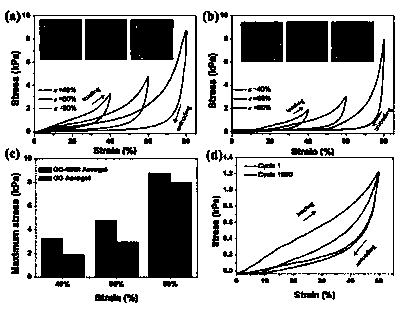

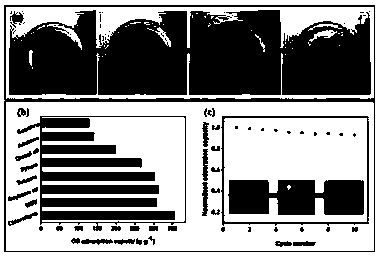

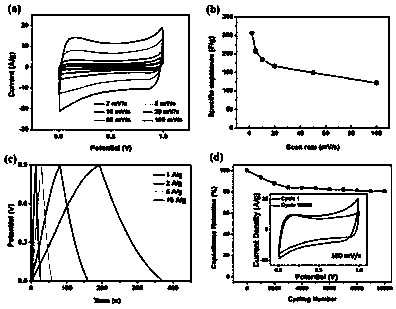

[0029] The method of preparation, characterization and performance testing of graphene-graphene nanoribbon sponge, using the gravimetric method to determine the concentration of graphene oxide (GO) and graphene oxide nanoribbon (GONR) solution, in mg / mL;

[0030] (2) According to the mass ratio of GO and GONR is 1:1, draw the corresponding volume of solution into the mold, stir and mix evenly;

[0031] (3) Freeze the well-mixed GO-GONR solution in the cold well of the freeze dryer for about 24 hours, then vacuumize and start freeze-drying. In order to ensure that the sample is completely dry, the freeze-drying time needs to be at least 48 hours;

[0032] (4) Take out the completely freeze-dried sample, which is the unreduced GO-GONR sponge, that is, graphene oxide-graphene oxide nanoribbon composite sponge;

[0033] (5) Place it in hydrazine hydrate vapor at 90°C for 24 hours, take it out after cooling to room temperature, put it in a vacuum drying oven at 100°C for 24 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com