Image forming method and printed image

A technology for printing images and images, applied in the field of image formation and printing images, to achieve the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0362]Using J Paper A4 manufactured by Konica Minolta Corporation as a recording medium, and using a modified AccurioPress C2060 as an output device, a fixed image of a 2 cm×2 cm square sheet was obtained using Toner 1 .

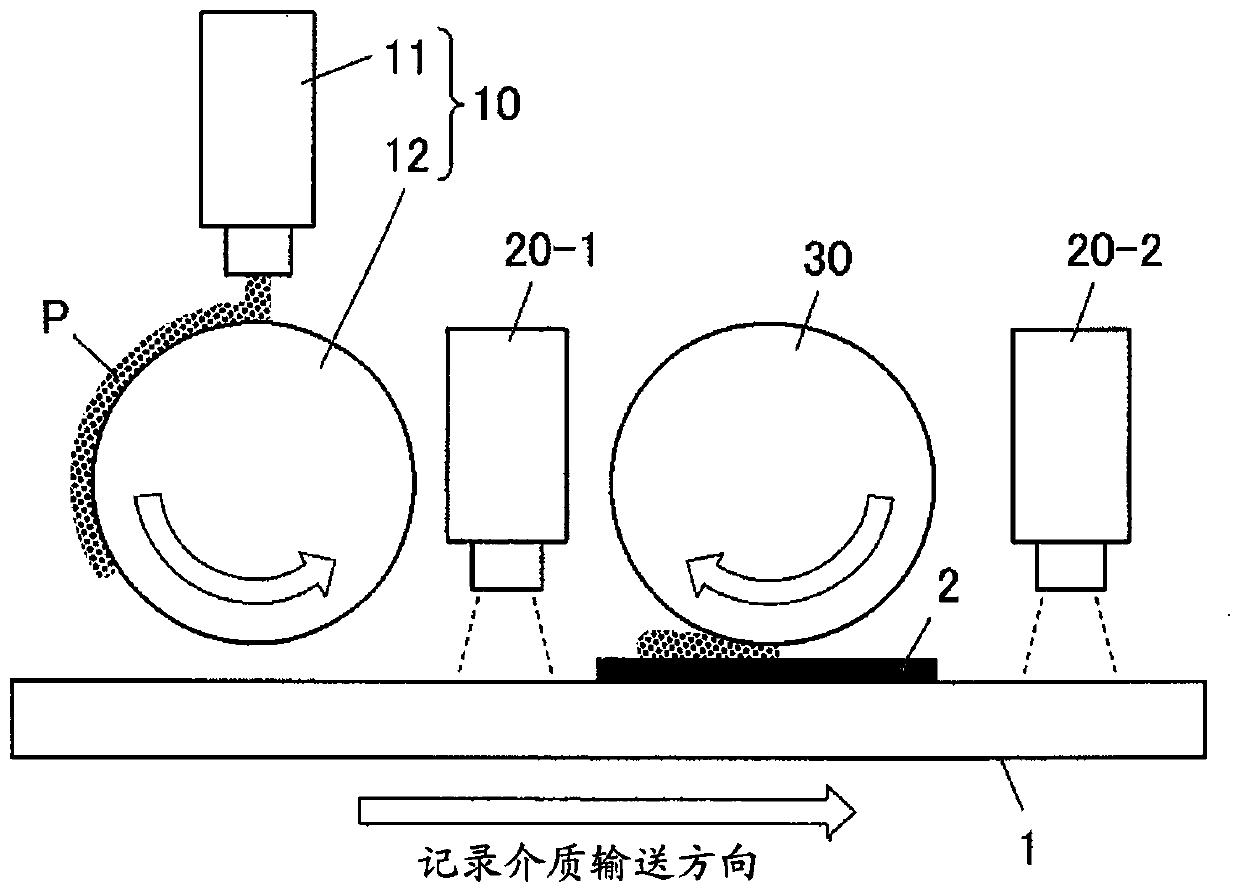

[0363] Set the above fixed image at figure 1 In the shown device, while moving it to the right, METASHINE 2025PS manufactured by Nippon Sheet Glass Co., Ltd. (shape: flake, thickness: 1 μm, average particle diameter 25 μm, composition: silver / glass, shown in Table 1 as 2025PS ), and then, irradiate 9J / cm through the illumination device 20-1 (light source: LED light source with emission wavelength of 365nm±10nm) 2 light, rub with a sponge roller. Further use the illumination device 20-2 (light source: LED light source with a light emission wavelength of 505nm±10nm) to irradiate 20J / cm 2 Light the amount of light, then use the bristles to remove the powder. The resulting image is a pearlescent style image. Irradiate 10J / cm by light in the same way 2 In th...

Embodiment 2

[0365] A plurality of parts having different decorative states are created on one image by one pass.

[0366] J Paper A4 manufactured by Konica Minolta Corporation was used as the recording medium, and a device modified from AccurioPress C2060 was used as the output device, and toner 1 was obtained on substantially the entire surface of A4 paper (19 cm × 27 cm). The fixed image of the solid image.

[0367] Set the fixed image of the solid image at figure 1 In the shown device, METASHINE 2025PS manufactured by Nippon Sheet Glass Co., Ltd. is scattered on the solid image while moving it to the right, and then, when passing through the illumination position, the illumination device 20-1 (light source: emission wavelength of 365nm ± 10nm LED light source) changes the amount of light to 9J / cm 2 、10J / cm 2 and 11J / cm 2 And light was irradiated, and then, it moved to the rubbing position, and rubbed with the sponge roller. Then, utilize the illumination device 20-2 (light source:...

Embodiment 3

[0369] Using J Paper A4 manufactured by Konica Minolta Corporation as a recording medium, and using a modified AccurioPress C2060 as an output device, a fixed image of a 2 cm×2 cm square sheet was obtained using Toner 1 .

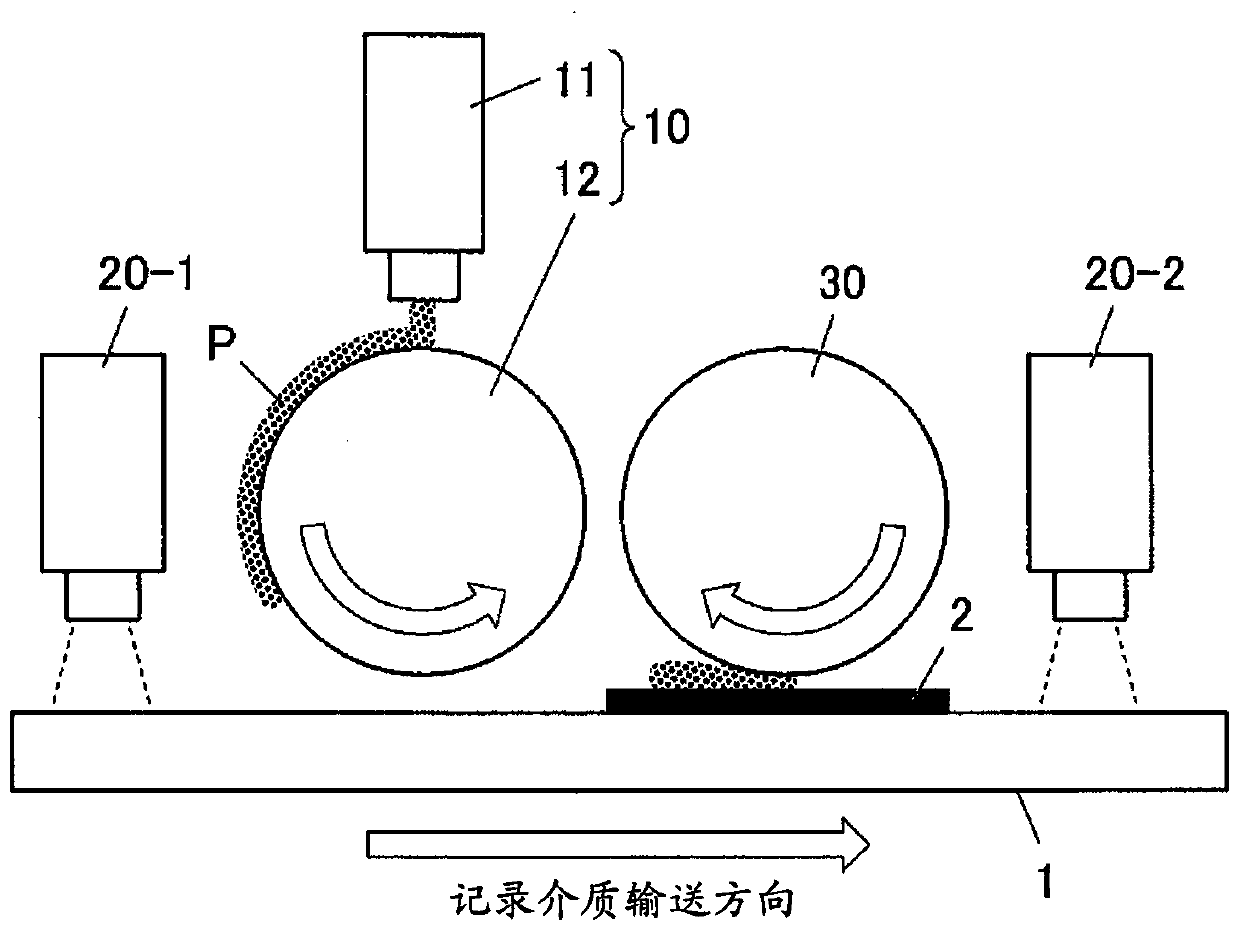

[0370] Set the above fixed image at figure 2 In the shown device, the toner is irradiated with light by the light source 20-1 (light source: an LED light source with an emission wavelength of 365nm ± 10nm) to melt or soften the toner, and then METASHINE 2025PS manufactured by Nippon Sheet Glass Co., Ltd. is spread, and then moved To the rubbing position, rub with a sponge roller. Further use the illumination device 20-2 (light source: LED light source with a light emission wavelength of 505nm±10nm) to irradiate 20J / cm 2 Light the amount of light, then use the bristles to remove the powder. The resulting image is a pearlescent style image. Irradiate 10J / cm by light in the same way 2 In the case of light with the same amount of light, the intermediate im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com