Conductive composite fiber bundle, preparation method thereof and organic electrochemical transistor

A technology of conductive composite fiber and conductive fiber, which is applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems that affect the conductivity and electrical properties of transistors, uneven distribution of nanowires, and blocked carrier transmission, etc., to achieve superior performance , multiple reaction sites, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

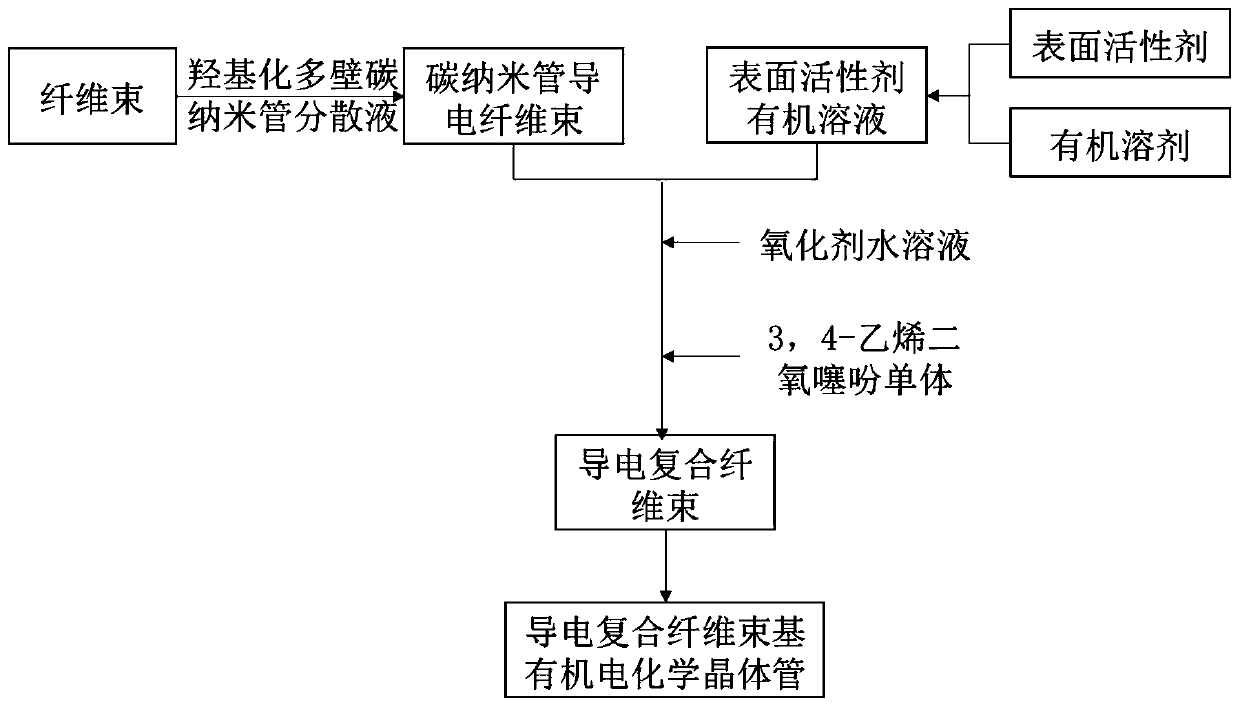

[0039] see figure 1 As shown, the preparation method of conductive composite fiber bundle and electromechanical chemical transistor provided by the invention comprises the following steps:

[0040] S1. Prepare a dispersion of hydroxylated multi-walled carbon nanotubes at a preset concentration, and then immerse the clean fiber bundles in it to prepare carbon nanotube conductive fiber bundles;

[0041] S2. Mixing the surfactant and the organic solvent at a preset temperature to prepare a surfactant organic solution with a preset concentration;

[0042] S3, mixing the oxidizing agent and deionized water at room temperature to prepare an aqueous oxidizing agent solution with a preset concentration;

[0043] S4. Under ice bath conditions, immerse the carbon nanotube conductive fiber bundle described in step S1 into the surfactant organic solution described in step S2, soak and stir; then add the oxidant aqueous solution described in step S3 according to the preset volume ratio I...

Embodiment 1

[0047] A conductive composite cotton fiber bundle, prepared by the following method:

[0048] S1. Preparation of carbon nanotube conductive cotton fiber bundles:

[0049] Put the cotton fiber monofilament into deionized water, absolute ethanol, and acetone in sequence for ultrasonic cleaning for 15 minutes to ensure that the previous step is cleaned well, and then proceed to the next step of cleaning after drying at room temperature. dry and save for later use;

[0050] Mix 0.2 g of hydroxylated multi-walled carbon nanotubes with 0.2 g of sodium lauryl sulfate and 100 ml of deionized water, and use a cell pulverizer to ultrasonically disperse the mixture for 1 hour, after which the cotton fiber bundles are repeatedly Immersed therein, the carbon nanotube conductive cotton fiber bundle is prepared.

[0051] S2. Preparation of surfactant organic solution:

[0052] Mix dioctyl sodium sulfonate succinate with a mass of 12 g and xylene with a volume of 80 ml at a temperature of ...

Embodiment 2~11

[0065] Compared with Example 1, Examples 2-11 differ in that the preparation conditions are shown in Table 1, and the others are basically the same as Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com