Polymerization terminator for rubber synthesis

A polymerization terminator and rubber technology, applied in the field of terminators, can solve problems such as harmful odor, equipment corrosion, large hydrogen sulfide, etc., and achieve the effect of improving product performance, low viscosity and good termination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Taking the production of styrene-butadiene rubber by emulsion polymerization as an example, in the polymerization water bath, a 2.0L polymerization kettle is used, and the polymerization kettle is subjected to vacuum and nitrogen replacement. Add soft water, soap solution, electrolyte solution, emulsifier, conditioner, styrene and butadiene into the polymerization kettle, when the temperature of the polymerization kettle drops to 4.5℃~5.5℃, add hydrogen peroxide to montane for polymerization In the experiment, when the conversion rate reached 60% to 70%, N-isopropylhydroxylamine and ionic liquid were added to the polymerization kettle at the same time. 0.1% by weight of styrene rubber, the ionic liquid includes n-butyl xanthate-tetramethyl quaternary ammonium salt.

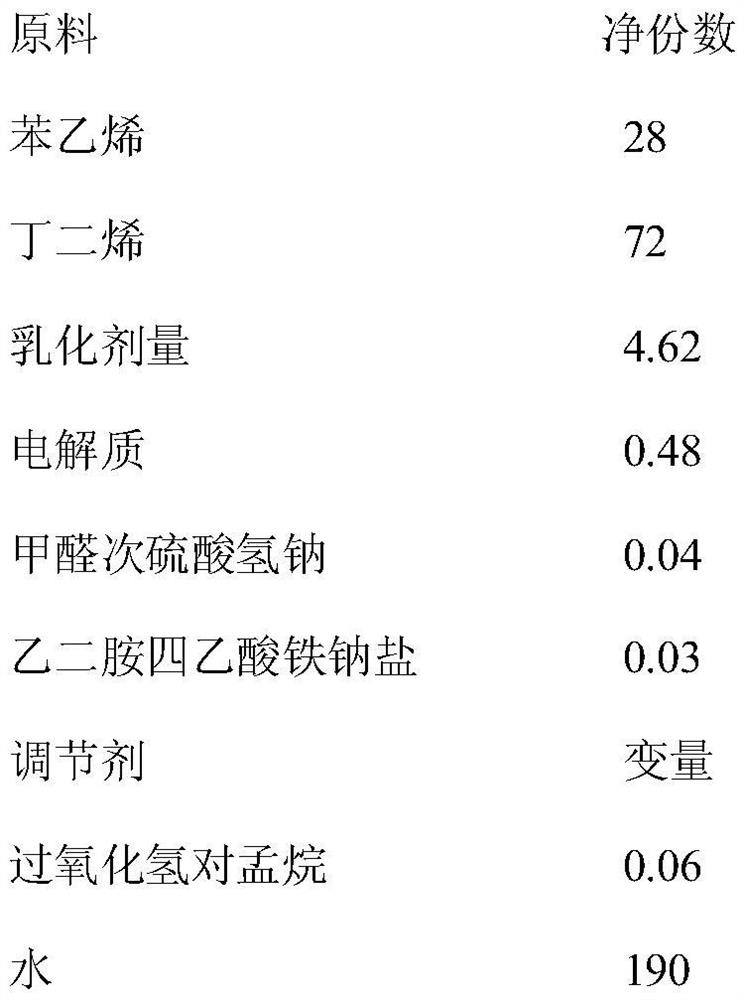

[0035] The above-mentioned polymer components and parts by weight are:

[0036]

Embodiment 2

[0038] The difference from Example 1 is that N-isopropylhydroxylamine accounts for 0.1% of the weight of the synthetic styrene-butadiene rubber, and the ionic liquid accounts for 0.06% of the weight of the synthetic styrene-butadiene rubber.

Embodiment 3

[0040] The difference from Example 1 is that N-isopropylhydroxylamine accounts for 0.06% of the weight of the synthetic styrene-butadiene rubber, and the ionic liquid accounts for 0.04% of the weight of the synthetic styrene-butadiene rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com