Memory module automatic test equipment

A technology for automatic testing equipment and memory testing, which is applied to conveyor objects, transportation and packaging, etc. It can solve the problems of memory testing production delays, low efficiency of manual operations, and inability to meet the needs of rapid inspection of qualified memory, and improve the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

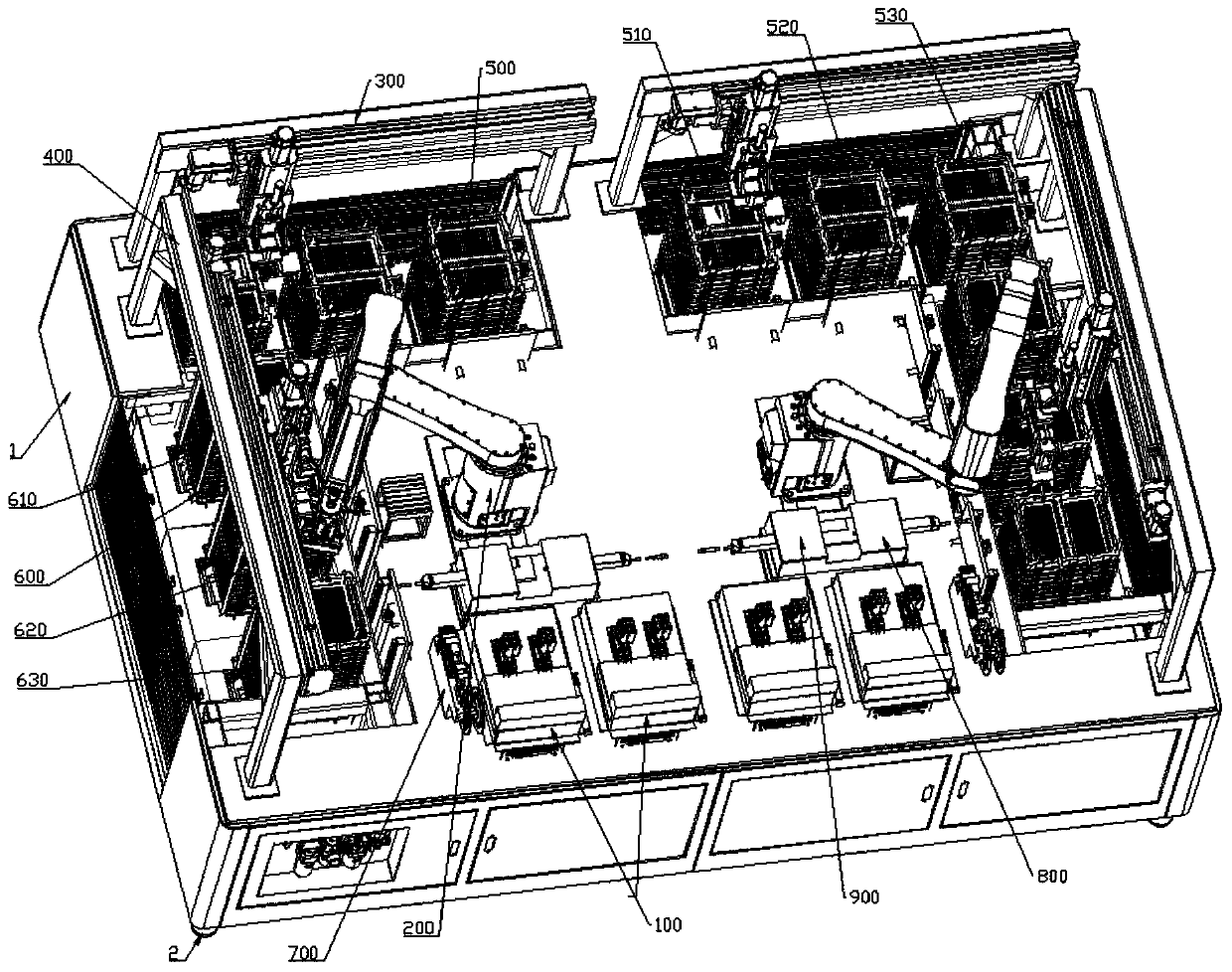

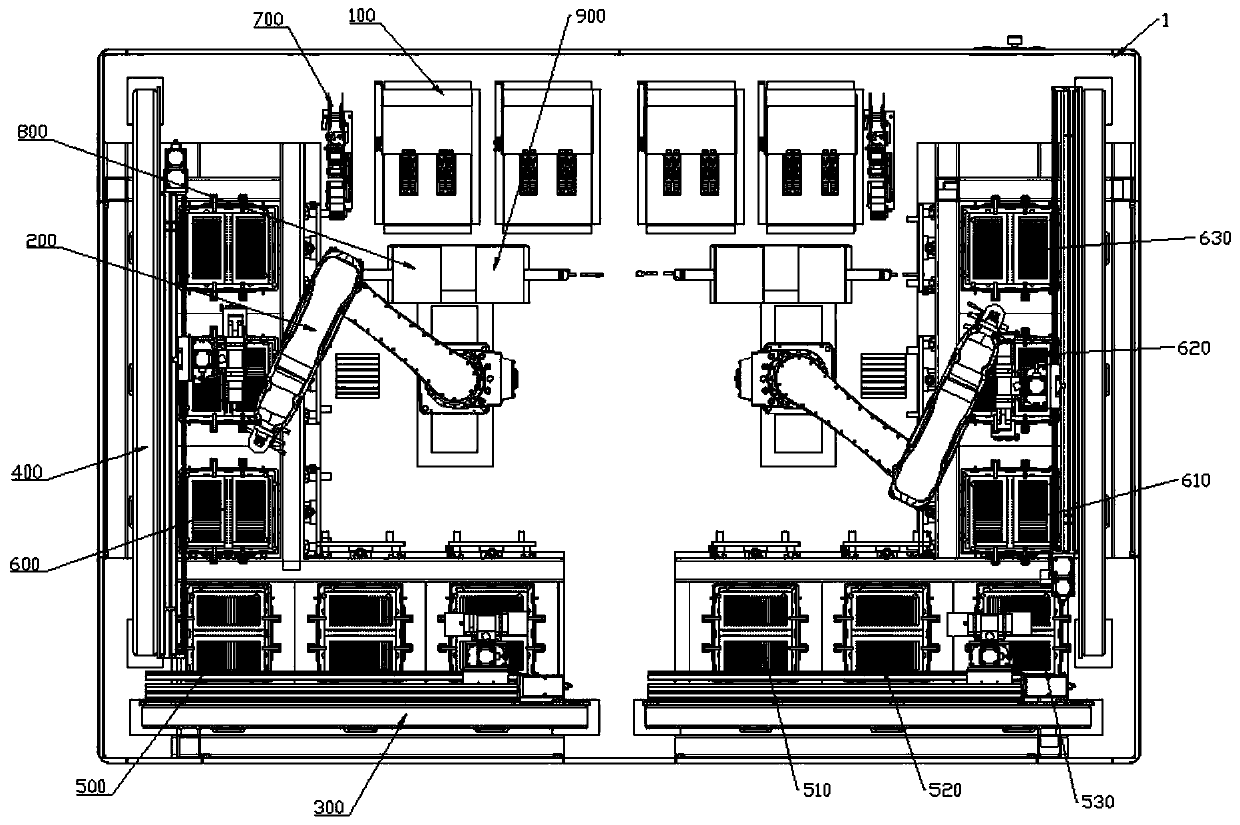

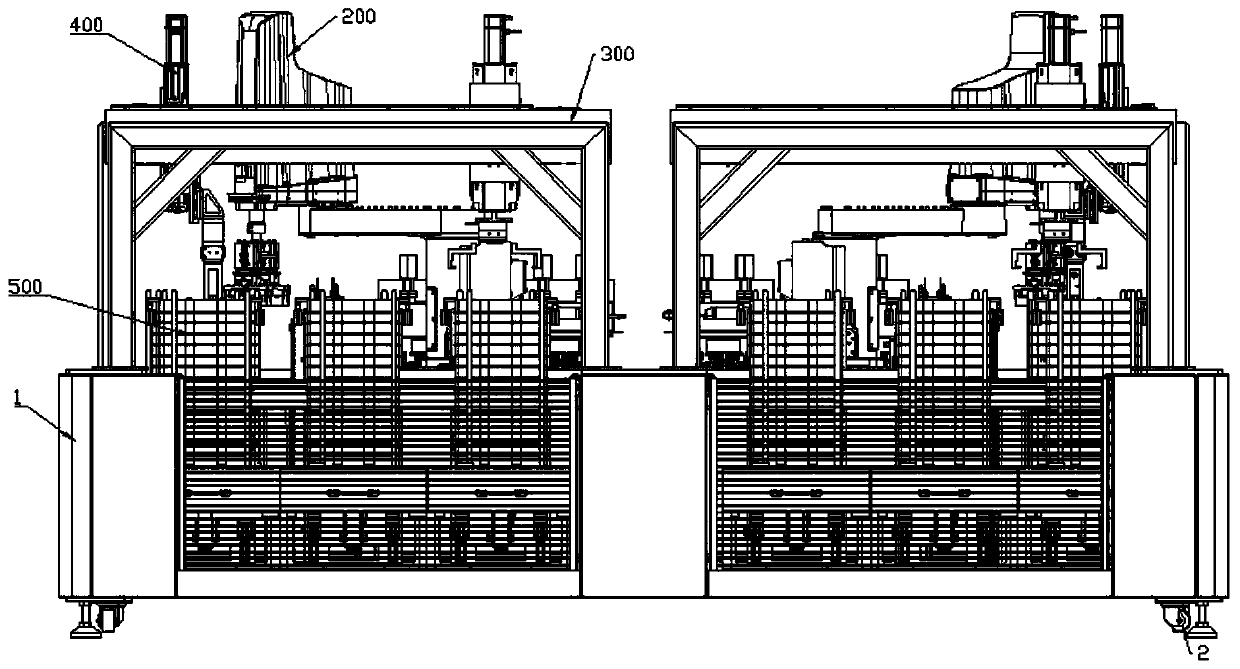

[0025] combine Figure 1 to Figure 8The shown automatic test equipment for memory sticks, in this embodiment, includes a rack platform 1 and two groups of test mechanisms arranged in a mirror image distribution on the rack platform 1, the test mechanism includes a manipulator 200, X-direction transfer and handling Station 300, Y-direction transfer station 400, X-direction material box module 500, Y-direction material box module 600, labeling machine 700, code scanning gun 800, ion fan 900 and memory tester 100; X-direction transfer The transfer station 300 includes an X-direction gantry frame 310 fixed on the rack platform 1, an X-direction electric slide table 320 fixed on the X-direction gantry frame 310, and a first Z axis connected to the slide block on the X-direction electric slide table 320. to the mounting plate 330, the first Z-direction electric slide 340 fixed on the first Z-direction The X-direction gripper mechanism 360 on the gripper mounting frame 350; the Y-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com