Inclined Bed Double Spindle CNC Lathe

A technology of CNC lathe and inclined bed, applied in the field of CNC machine tools, can solve problems such as insufficient lubrication of guide rails, low machining accuracy, and reduced parts accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

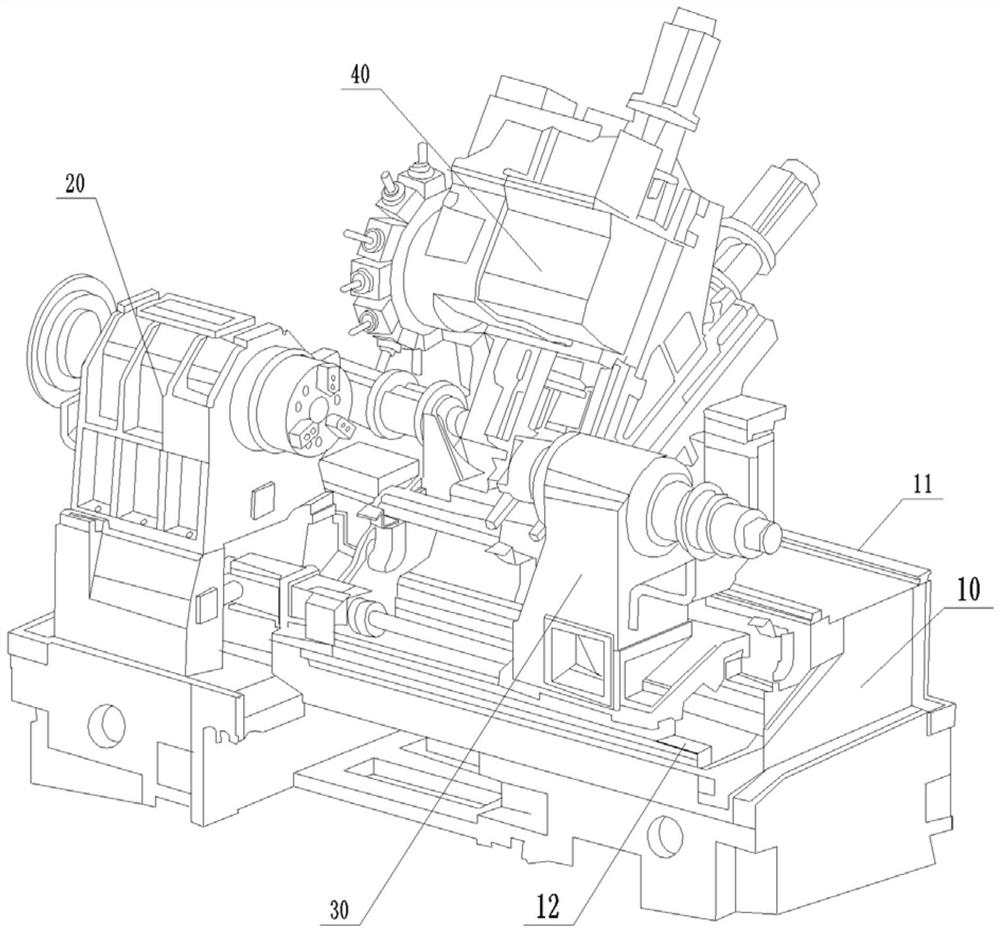

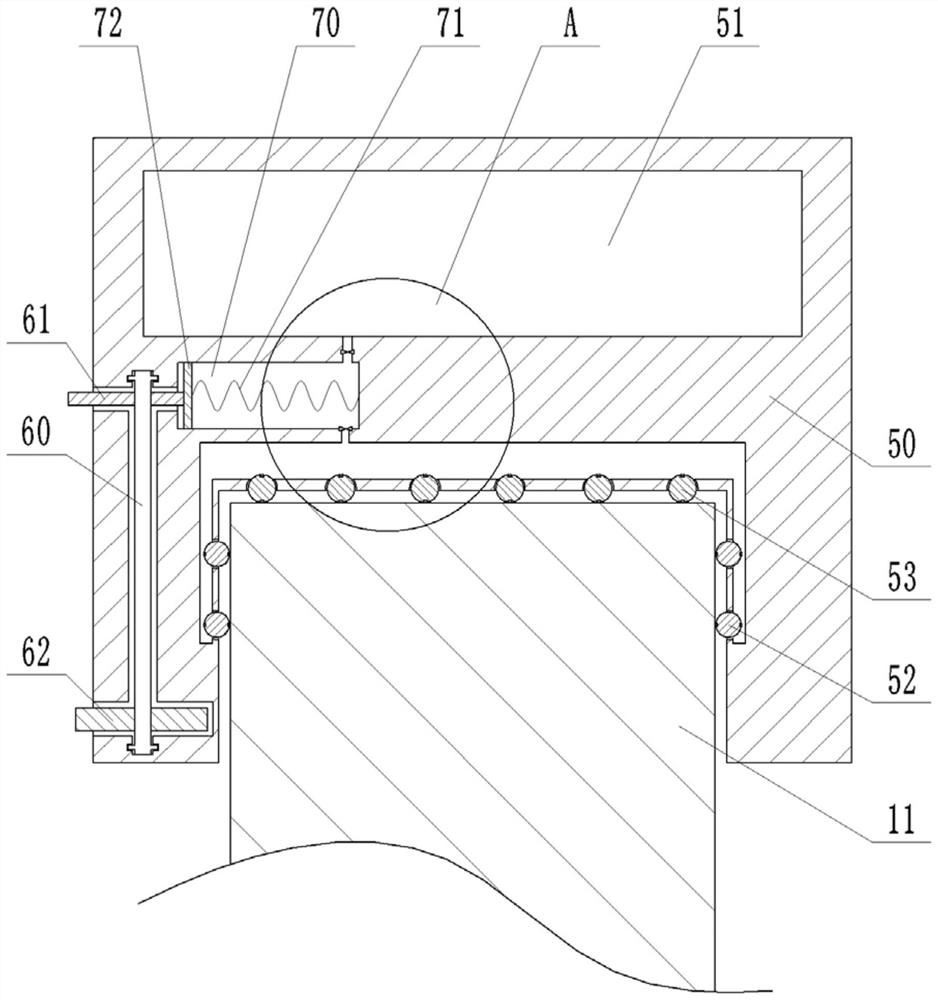

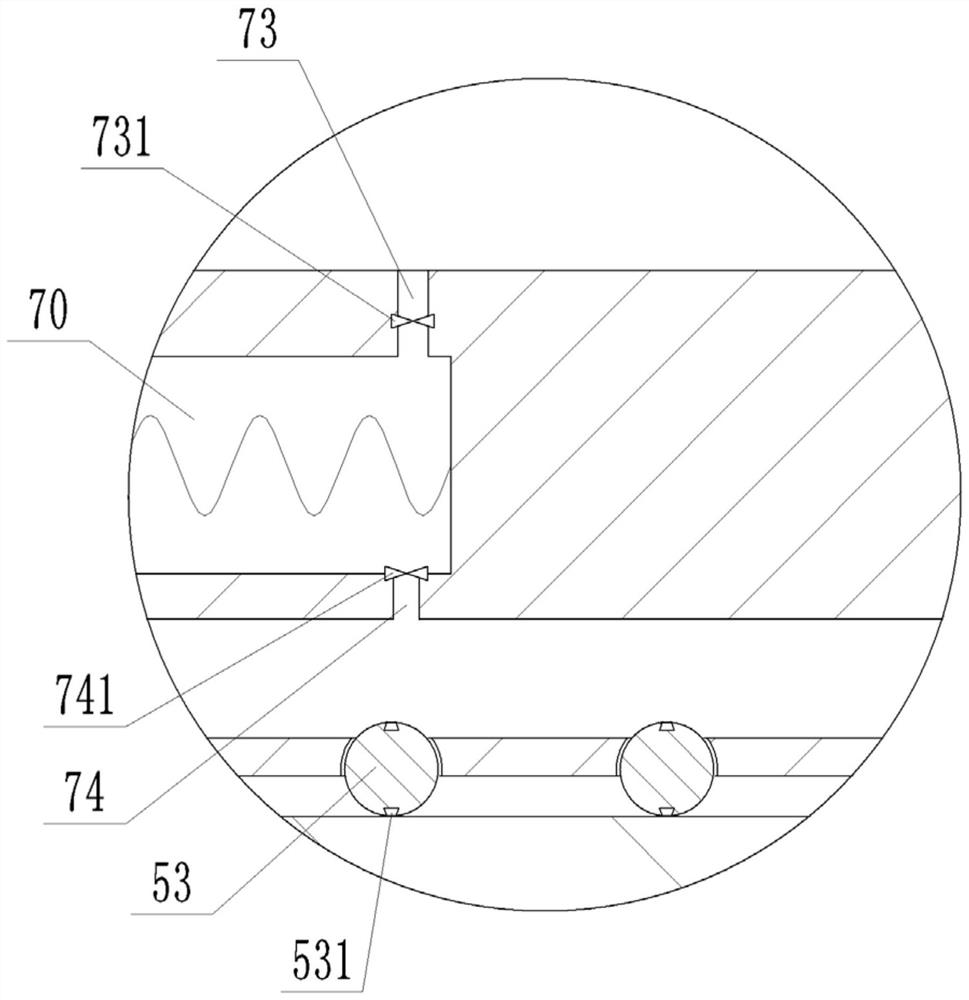

[0027] This embodiment is basically as figure 1 Shown: Slanted bed double-spindle CNC lathe, including hydraulic station, cooling system, protective cover and programmable control board, and the protective cover is equipped with a door that can be opened and closed. A slanted bed 10 is installed in the protective cover, and a first main shaft assembly 20, a second main shaft assembly 30 and a saddle assembly 40 are arranged on the slanted bed 10. The first main shaft assembly 20 is similar in structure to the second main shaft assembly 30, Both the first main shaft assembly 20 and the saddle assembly 40 are existing devices, and their specific structures will not be repeated here. Two saddle guide rails 11 and two second spindle guide rails 12 are also fixedly installed on the guide rail mounting surface of the inclined bed 10, and both the saddle guide rails 11 and the second spindle guide rails 12 are slidably connected with slide blocks 50, the saddle assembly 40 is slidab...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, in this implementation, an oiling layer is fixed at the oil outlet. In this embodiment, the oiling layer is a sponge layer 54, and the lubricating oil flowing out from the oil outlet cylinder 70 is applied on the surface of the saddle guide rail 11 through the sponge layer 54. .

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that: Figure 5 , Figure 6 As shown, the direction in which the oil outlet cylinder 70 is arranged and the specific structure of the power mechanism are different from the first embodiment. In this embodiment, the opening of the oil outlet cylinder 70 faces downward, and the piston 72 can slide up and down along the inner wall of the oil outlet cylinder 70 . The power mechanism comprises a threaded rod 80, a second gear 81 and a second rack meshed with the second gear 81, the threaded rod 80 is rotatably connected in the slide block 50, the second gear 81 is welded on the threaded rod 80, and the first rack Fixedly installed on the inclined bed 10, the length of the second rack can be reasonably set according to actual needs. The threaded rod 80 passes through the piston 72 and is threadedly connected with the piston 72; the stopper that restricts the rotation of the piston 72 is fixed in the oil outlet cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com