Production process method of aquatic feed

A production process and aquatic feed technology, applied in the molding or processing of animal feed, feed, animal feed, etc., can solve the problems of insimplified process flow, low mixing uniformity requirements, and inability to make full use of equipment, so as to save equipment Investment and plant construction investment, high requirements for mixing uniformity, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

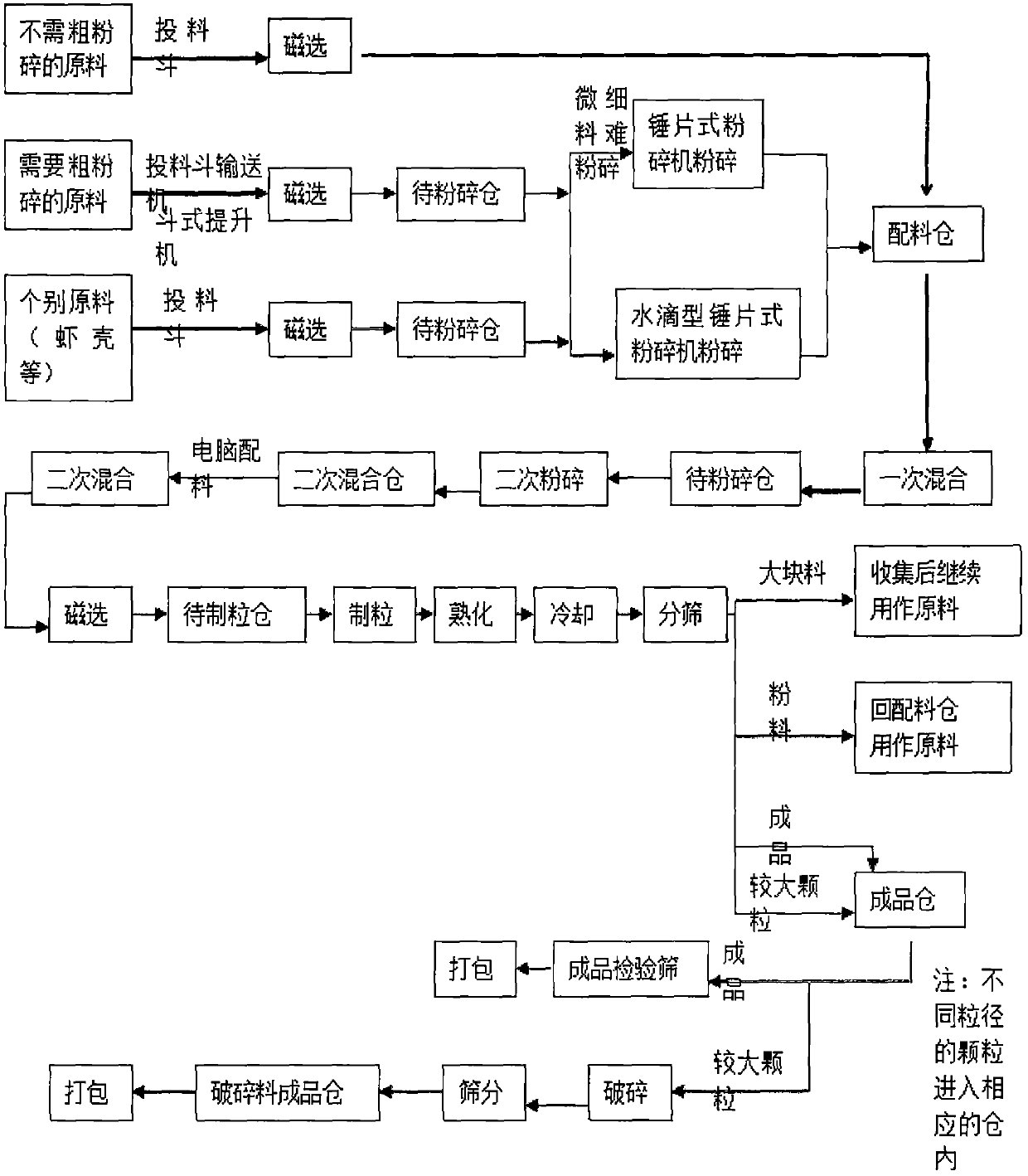

[0025] see figure 1 As shown, the technical solution adopted in this specific embodiment is: it comprises the following steps:

[0026] Raw material receiving and primary crushing--primary batching and mixing--secondary crushing and secondary batching mixing--granulation section--processing and packaging of finished fish feed--processing and packaging of finished shrimp feed--expanded granulation section and finished products deal with,

[0027] 1. Raw material reception and primary crushing: domestic fish meal, imported fish meal, chicken meal, pork meal, flour, hemoglobin, and calcium dihydrogen are placed on the No. 1 feeding line, and the raw materials pass through self-cleaning scraper conveyor, bucket type The hoist enters the cleaning equipment for magnetic separation of impurities, and then enters the batching bin through the 16-station distributor; soybean meal, rapeseed meal, cotton meal, peanut meal, rice bran, corn, and wheat are placed on the No. 2 feeding line, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com