Rotary bin cleaning device

A technology of cleaning device and rotating silo, applied in the field of kitchen appliances, can solve the problems of not easy to dry the rotating silo, easily mildewed and polluted materials, unable to clean the rotating silo, etc., to achieve good cleaning effect, avoid water vapor accumulation, and avoid too wet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

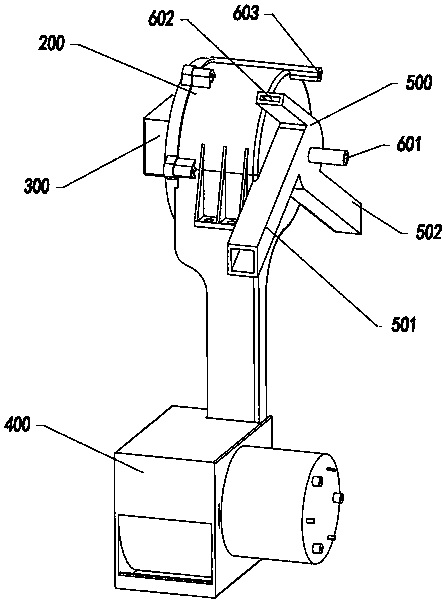

[0036] In this embodiment, if figure 1 As shown, it is a rotary bin cleaning device for cleaning materials. The materials can be grains, beans and other materials, such as rice, black rice, glutinous rice, millet, corn, soybeans, red beans, mung beans, etc. This rotary bin The cleaning device can be used together with the cooking utensils to provide clean and hygienic materials for the cooking utensils. At the same time, the rotary bin cleaning device can also be used alone to complete the automatic cleaning of materials and save manpower and material resources.

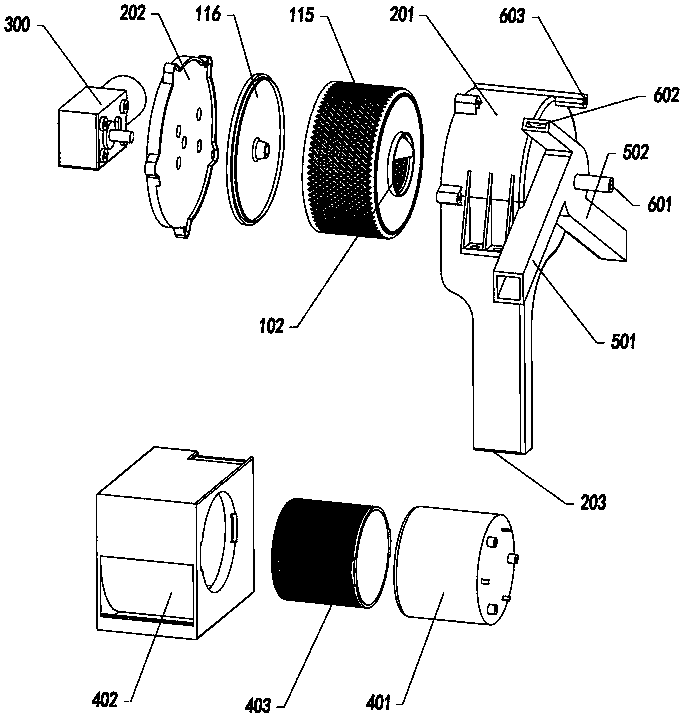

[0037] refer to figure 2 , the rotary bin cleaning device of the present embodiment includes a rotary bin 100 and a steam supply unit (not shown), the rotary bin 100 includes a material port, a turning blade and a filter screen, and the material port is used for the inlet and outlet of the rotary bin 100; the steam supply unit The cleaning water vapor is provided for the rotary bin 100, so that the materials are cl...

Embodiment 2

[0102] When it is necessary to clean the interior of the rotary bin to remove dust, harmful substances and other impurities attached to the inner surface of the rotary bin due to dry cleaning, the steam supply unit can provide cleaning water to the rotary bin to clean the rotary bin. No materials are provided, just idling.

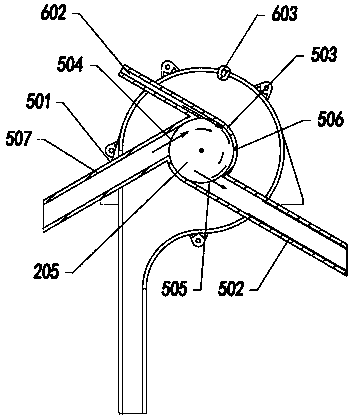

[0103] Such as Figure 4 and Figure 5 As shown, in order to realize the cleaning of the rotating bin itself, the rotating bin cleaning device of this embodiment includes a housing, a rotating bin, a steam supply unit and an air extraction device, the rotating bin is arranged in the housing, and the rotating bin There is a material port, the housing is provided with a sewage outlet and a material window, the material window is set opposite to the material port, the air extraction device is connected to the sewage outlet, and the steam supply unit is the rotating The bin provides cleaning water vapor to clean the inside of the rotating bin, and the air ex...

Embodiment 3

[0112] When it is necessary to clean the inner wall of the housing to remove dust, harmful substances and other impurities attached to the inner surface of the housing due to dry cleaning, the steam supply unit can provide cleaning water vapor to the rotating chamber to clean the rotating chamber. Material cleaning is not carried out, and it can be turned or not.

[0113] Such as Figure 4 , 5 As shown, in order to realize the cleaning of the housing itself, the rotating bin cleaning device of this embodiment includes a housing, a rotating bin, a steam supply unit and an air extraction device, the rotating bin is arranged in the housing, and the housing A cleaning port 603 and a sewage discharge port are provided, the air extraction device is connected to the sewage discharge port, and the steam supply unit provides cleaning water vapor for the housing through the cleaning port 603 to clean the inside of the housing. The air extraction device extracts the cleaned water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com