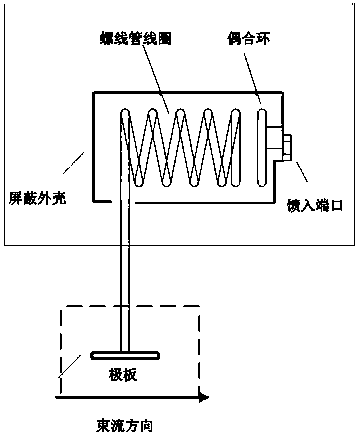

DC beam cutting device based on sine wave waveforms

A cutting device, sine wave technology, applied in the direction of accelerators, electrical components, etc., can solve the problem that the spiral resonator cannot guarantee the high precision of the natural frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

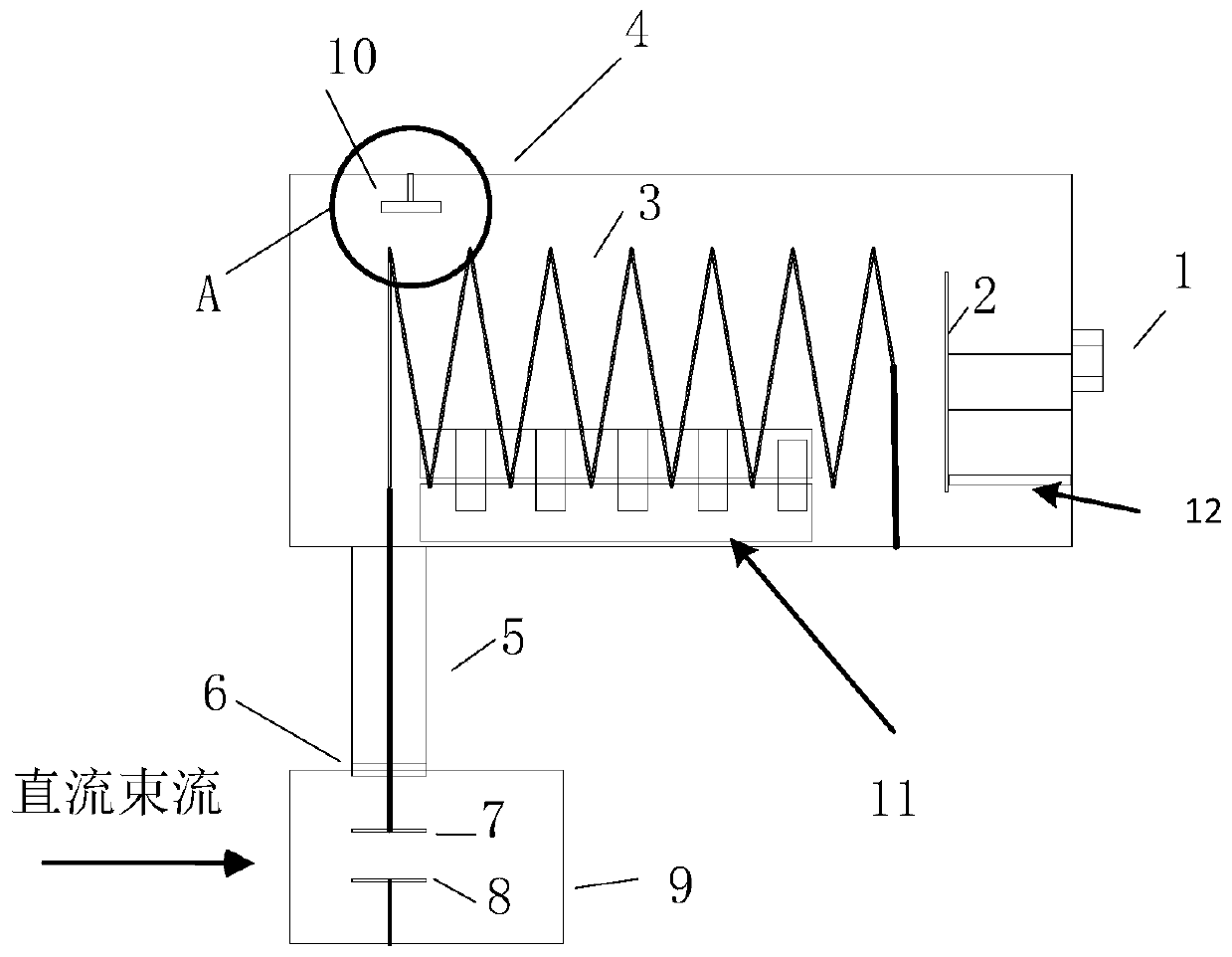

Embodiment 1

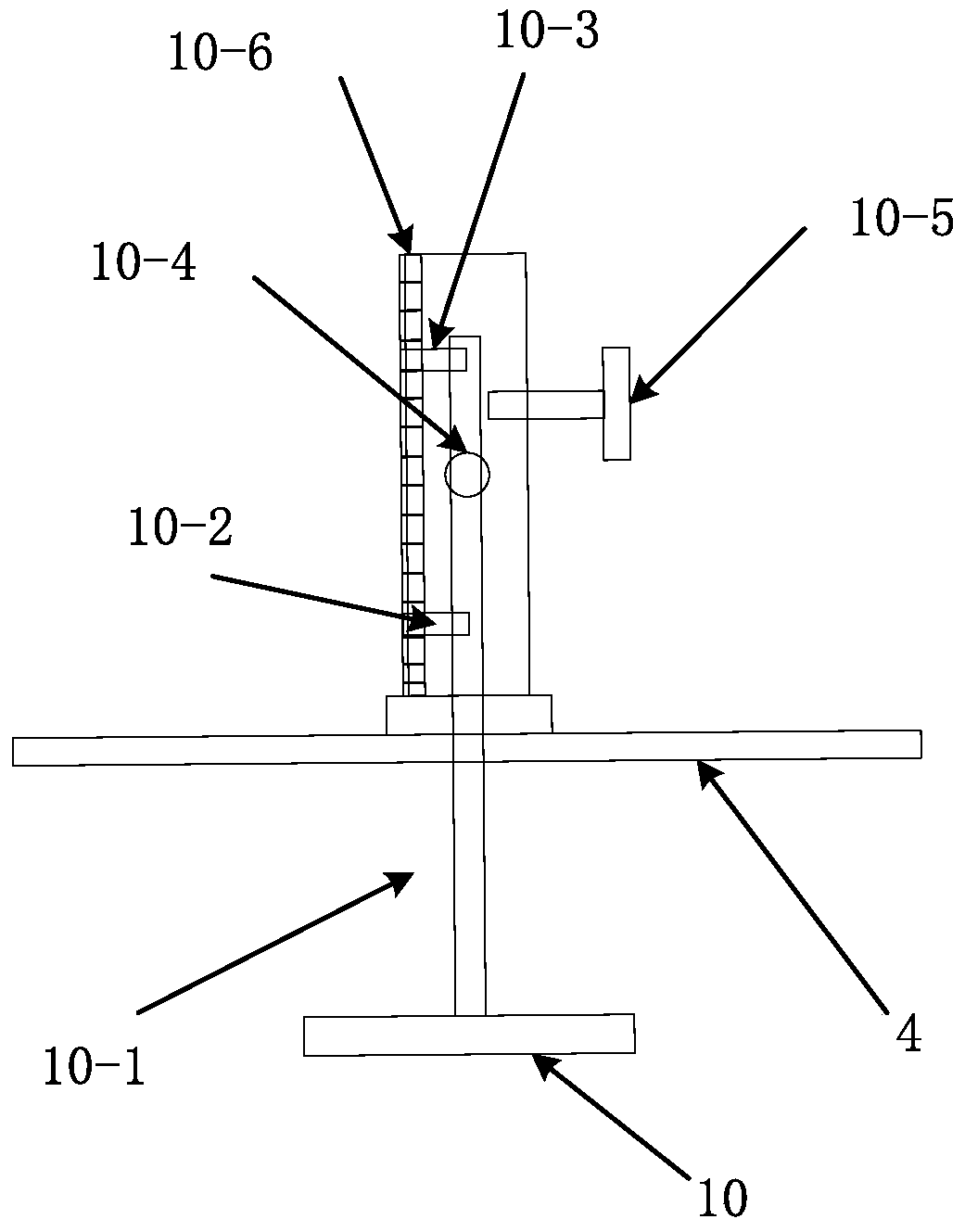

[0042] 1. The specific method of adjusting the front and rear positions of the coupling ring. By manually rotating the forward and reverse of the adjustment knob, the threaded telescopic rod drives the coupling coil to move forward and backward. At the same time, use a network analyzer to test the transmission power. When the transmission power is greater than 88.9%, it is considered that most of the power has been fed in, and it is acceptable. Within the range, and take the position of the coupling coil at this time as the final fixed position.

[0043] 2. The method of adjusting the capacitor plate. Set the front and rear positions of the capacitor plate by manually controlling the adjustment knob, and use a network analyzer to measure the frequency during the movement. First, measure the frequency parameters of the helical resonator at the maximum stroke and the minimum stroke, so as to determine the spiral resonance of the capacitance fine-tuning plate According to the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com