Cable joint and connecting method thereof

A technology for cable joints and cables, which is used in equipment for connecting/terminating cables, gas-filled/oil-filled cable accessories, etc., can solve problems such as poor sealing, easy disconnection, easy bumping, etc., to reduce failures and safety hazards, Avoid disconnecting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

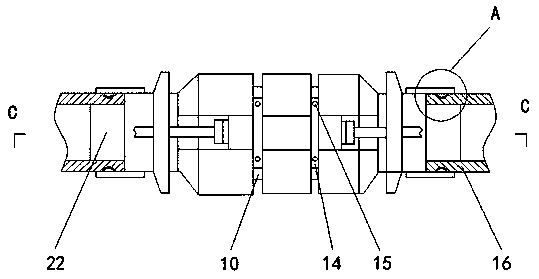

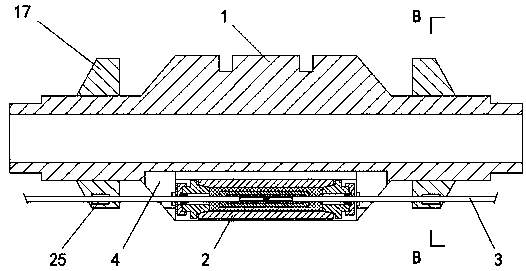

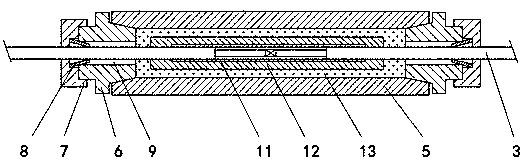

[0037] The embodiment of the present invention provides a cable joint and its connection method, aiming to solve the problems of easy bumping, easy disconnection, poor sealing and complicated binding process existing in the connection of cables used in oil field water wells.

[0038]By placing the hinged cable 3 in the sealing part 2, the sealing part 2 is fixedly connected to the U-shaped notch 4 on the side of the eccentric tube 1, so that the entire sealing part 2 is accommodated in the U-shaped notch 4. During the process, the eccentric tube 1 can effectively prevent the sealing part 2 from colliding with the bushing, thereby avoiding disconnection of the cable.

[0039] By injecting the sealing silicone grease 13 into the sealing nipple 5, the air in the sealing nipple 5 is displaced by the sealing silicone grease 13, so that the cable 3 can be completely isolated from the air, thereby reducing failures and potential safety hazards.

[0040] In addition, by setting the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com