Method and system for controlling liquid level of vapor-liquid separator in polycrystalline silicon cold hydrogenation production

A vapor-liquid separator, cold hydrogenation technology, applied in the control/regulation system, liquid level control, non-electric variable control and other directions, can solve problems such as the difficulty of liquid discharge of the vapor-liquid separator, achieve the degree of automation of sustainable operation, solve the The effect of difficult drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

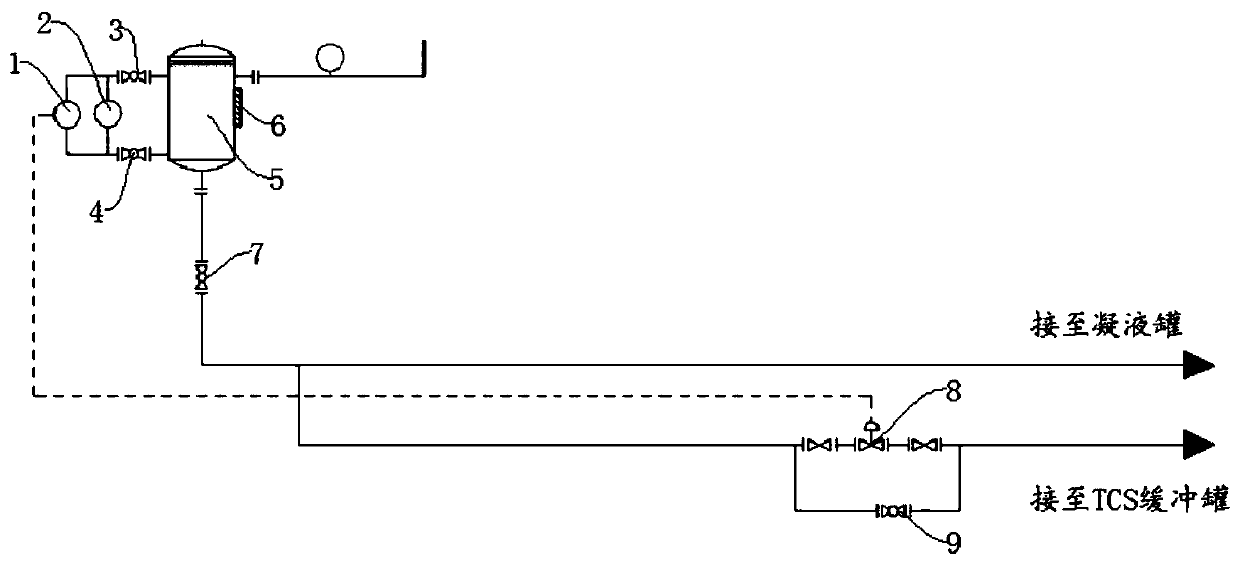

[0029] Such as figure 1 As shown, the method for controlling the liquid level of the vapor-liquid separator 5 in the cold hydrogenation production of polysilicon includes:

[0030] Retrofit of vapor-liquid separator 5: installing a thermometer on vapor-liquid separator 5 ( figure 1 Among them is the first thermometer 6) and a liquid level gauge, and the thermometer is used to measure the temperature of the silane liquid in the vapor-liquid separator 5, and the liquid level gauge is used to detect the liquid level of the silane liquid in the vapor-liquid separator 5; The outlet of 5 is provided with a regulating valve ( figure 1 Among them is the third ball valve 7), the regulating valve is used to regulate the liquid level of silane liquid (trichlorosilane and / or silicon tetrachloride) in the vapor-liquid separator 5, and the silane liquid level in the vapor-liquid separator 5 Control within the target range;

[0031] Set up liquid storage: Liquid storage includes condensat...

Embodiment 2

[0036] This embodiment is similar to the first embodiment, the difference is that many technical features have been improved in this embodiment, so that the overall solution is more complete and the effect is more prominent.

[0037] The number of condensate intermediate tanks and TCS buffer tanks is at least one, and a liquid outlet main pipe is drawn from the vapor-liquid separator 5. The liquid outlet main pipe is connected to several branch pipes, and each branch pipe is connected to the condensate intermediate tank or TCS buffer tank.

[0038] A regulating valve is arranged on the liquid outlet main pipe, and the regulating valve is a ball valve.

[0039] A regulating valve is arranged on each branch pipe, and the regulating valve is a ball valve. A controlled regulating valve 8 is also arranged on the branch pipe connected to the TCS buffer tank. The controlled regulating valve 8 is electrically connected with the remote liquid level gauge 1, and the opening and closing ...

Embodiment 3

[0046] Such as figure 1 As shown, a system for controlling the liquid level of the vapor-liquid separator 5 in polysilicon cold hydrogenation production, the system includes:

[0047] Part 5 of vapor-liquid separator: install a thermometer on vapor-liquid separator 5 ( figure 1 Among them is the first thermometer 6) and a liquid level gauge, and the thermometer is used to measure the temperature of the silane liquid in the vapor-liquid separator 5, and the liquid level gauge is used to detect the liquid level of the silane liquid in the vapor-liquid separator 5; The outlet of 5 is provided with a regulating valve ( figure 1 Among them is the third ball valve 7), the regulating valve is used to regulate the liquid level of the silane liquid in the vapor-liquid separator 5, and the liquid level of the silane liquid in the vapor-liquid separator 5 is controlled within the index range;

[0048] Liquid storage equipment part: The liquid storage equipment includes a condensate int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com