Progressive setting method for PID parameters

A parameter tuning and progressive technology, applied in the field of progressive tuning of PID parameters, can solve the problems of model credibility reduction, the quality of tuning depends on the quality of the model, etc., and achieve the effect of avoiding model errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In order to solve the problem of setting the PID controller parameters in the industrial process control in the prior art. This application proposes a progressive tuning method for PID parameters. By using this tuning method, the tedious modeling process and the deviation caused by modeling can be bypassed, and the corresponding PID controller parameters can be directly tuned to meet or approach the preset parameters. The set closed-loop control performance target.

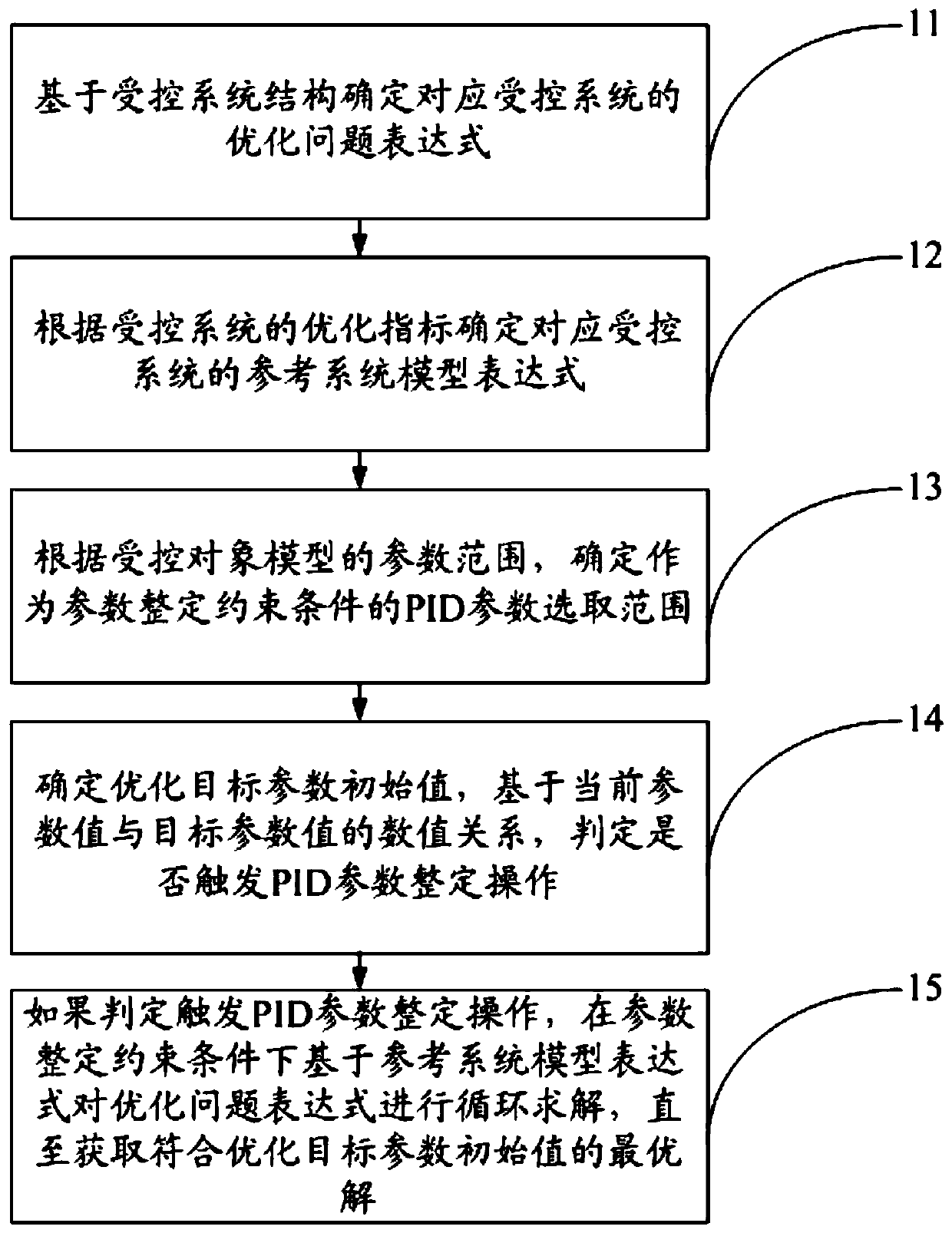

[0067] Specifically, the progressive tuning method for PID parameters provided by this application, such as figure 1 shown, including:

[0068] 11. Determine the optimization problem expression corresponding to the controlled system based on the controlled system structure;

[0069] 12. Determine the reference system model expression corresponding to the controlled system according to the optimization index of the controlled system;

[0070] 13. According to the parameter range of the controlled object m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com