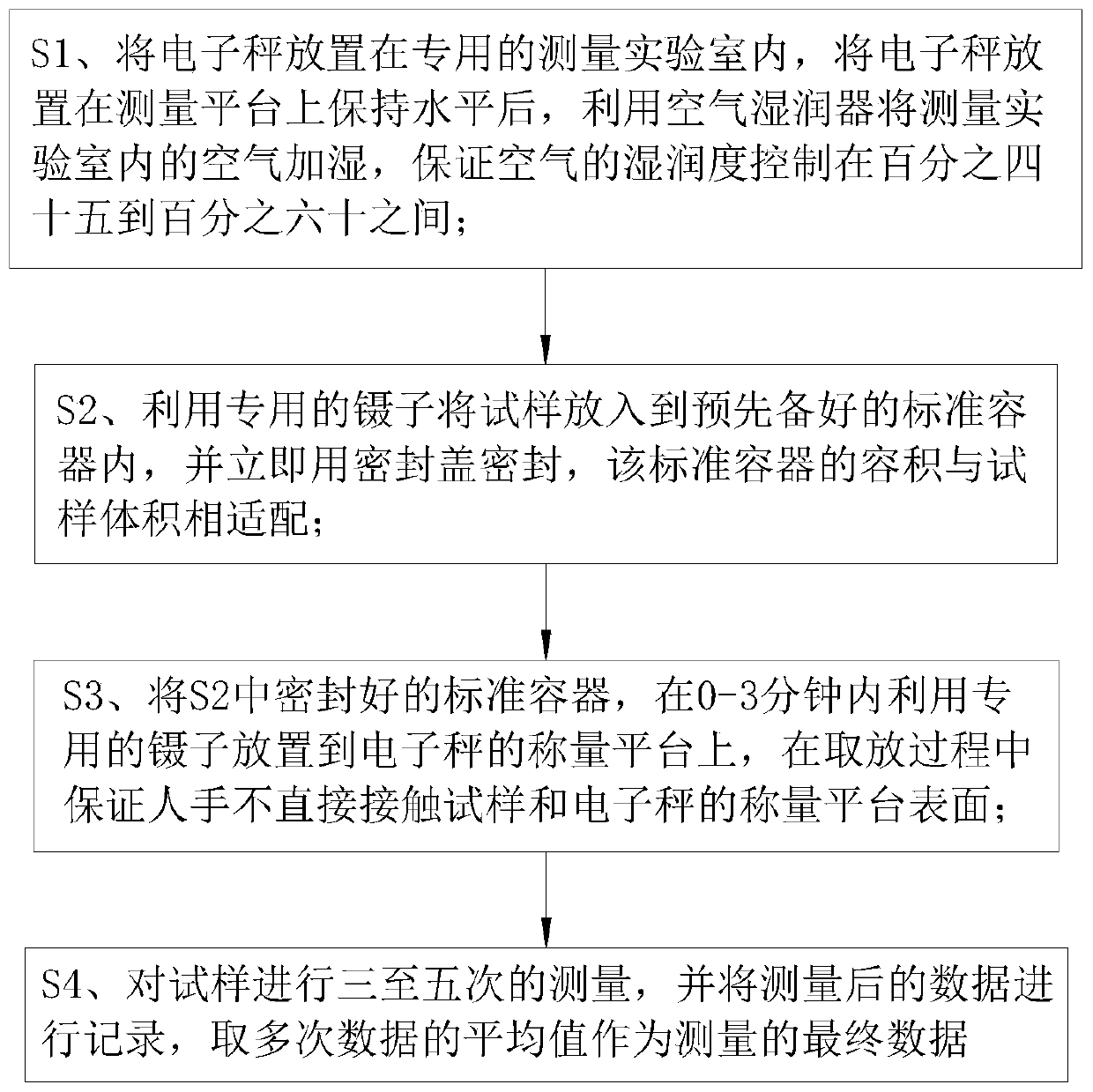

Measurement method of micro-weighing electronic scale

A measurement method and technology of electronic scales, applied in the field of measurement, can solve the problems affecting the accuracy of the weighing results of the measured objects, the accuracy of the measurement results, etc., and achieve the effects of avoiding sweat residue, reducing time, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

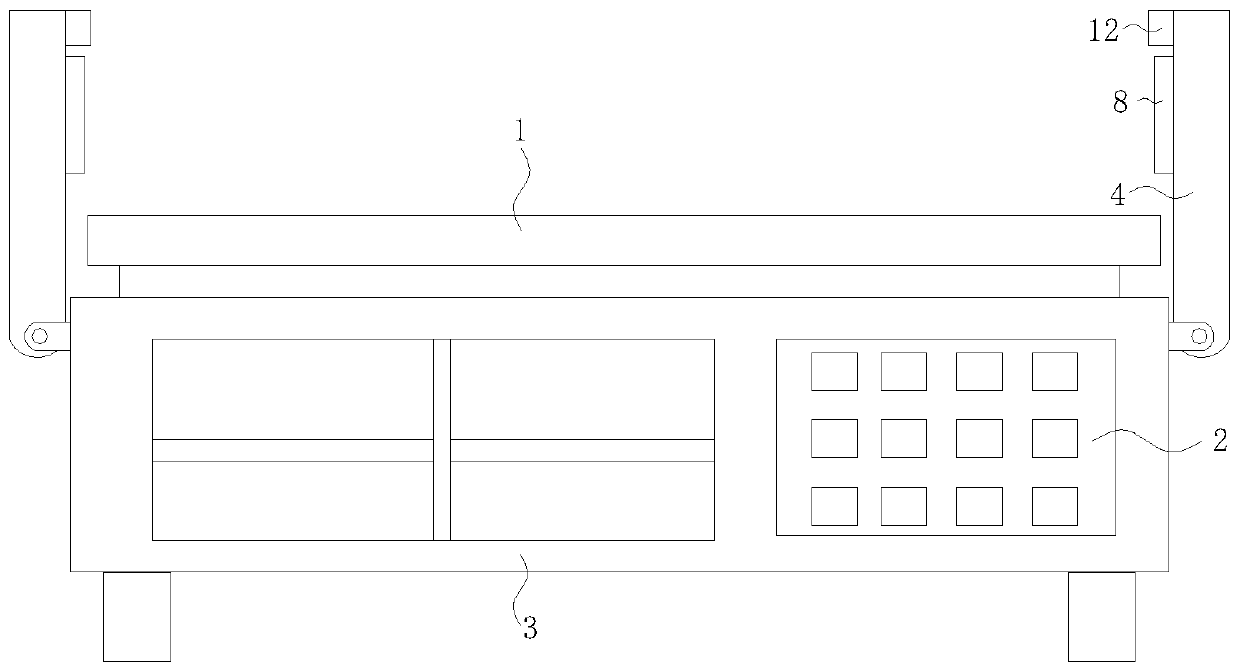

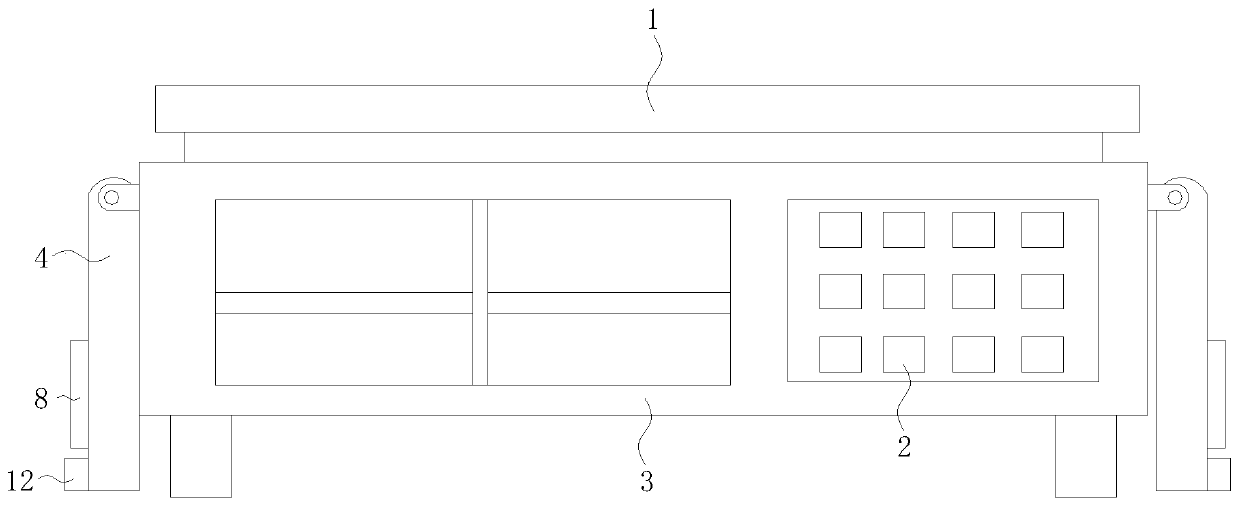

Image

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the standard container and the sealing cover are made of non-metallic materials, and the standard container and the sealing cover are in an interference fit to form a sealed cavity inside the standard container; During the weighing process, tiny powder samples, weighing paper, and glass containers are very likely to generate static electricity due to friction, and the electrostatic force generated will directly affect the weighing results, while standard containers and sealing covers made of non-metallic materials Poor conductivity, it can sufficiently seal the sample, and at the same time isolate the static electricity on the sample, so as to ensure that the static electricity on the sample will not interfere with the accurate measurement of the electronic scale. During the weighing process, the interference force The appearance is caused by the interaction of charges, so the influence of static electricity on the weighing resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com