Homogenizing valve for high-pressure homogenizer

A technology of high-pressure homogenizer and homogenizer valve, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of affecting the continuity of product production, shortening the service life of impact ring, increasing production cost, etc., to reduce shearing force and impact, extended service life, guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

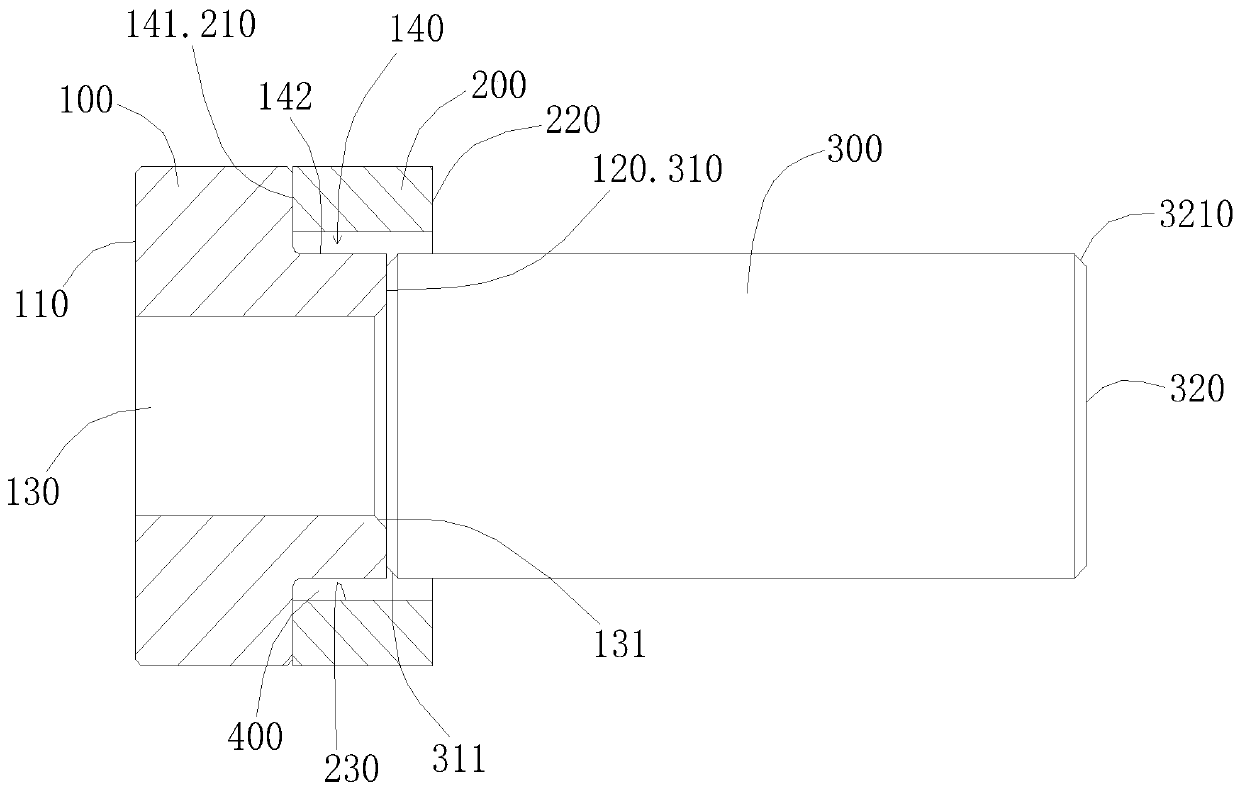

[0017] see figure 1 , shown in the figure is a homogenizing valve for a high-pressure homogenizer, including a valve seat 100, an impact ring 200 and a valve core 300. In this embodiment, the valve seat 100, the impact ring 200 and the valve core 300 are all made of Made of ceramic materials, effectively reducing the cost of homogenizing valves.

[0018] The valve seat 100 is cylindrical, and there is a material channel 130 axially passing through its front and rear end surfaces 110, 120. The inner surface of the outlet end of the material channel 110 is a tapered surface 111 with a small front and a large rear. A stepped surface 140 is provided on the outer peripheral surface of 100 at the outlet end of material channel 110 .

[0019] The imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com