One-way moisture wicking needled composite multilayer wadding and preparation method thereof

A needle-punched compound, one-way moisture-conducting technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as difficulty in direct contact with the human body for long-term use, reagent pollution, and poor one-way moisture-conducting effect, etc., to maintain heat and humidity Comfort and long-term use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

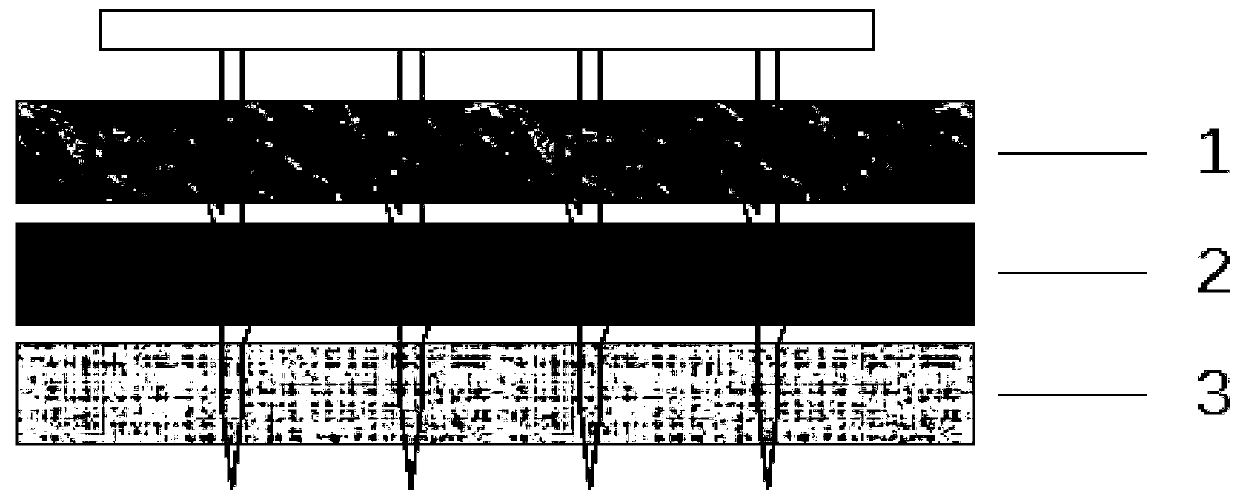

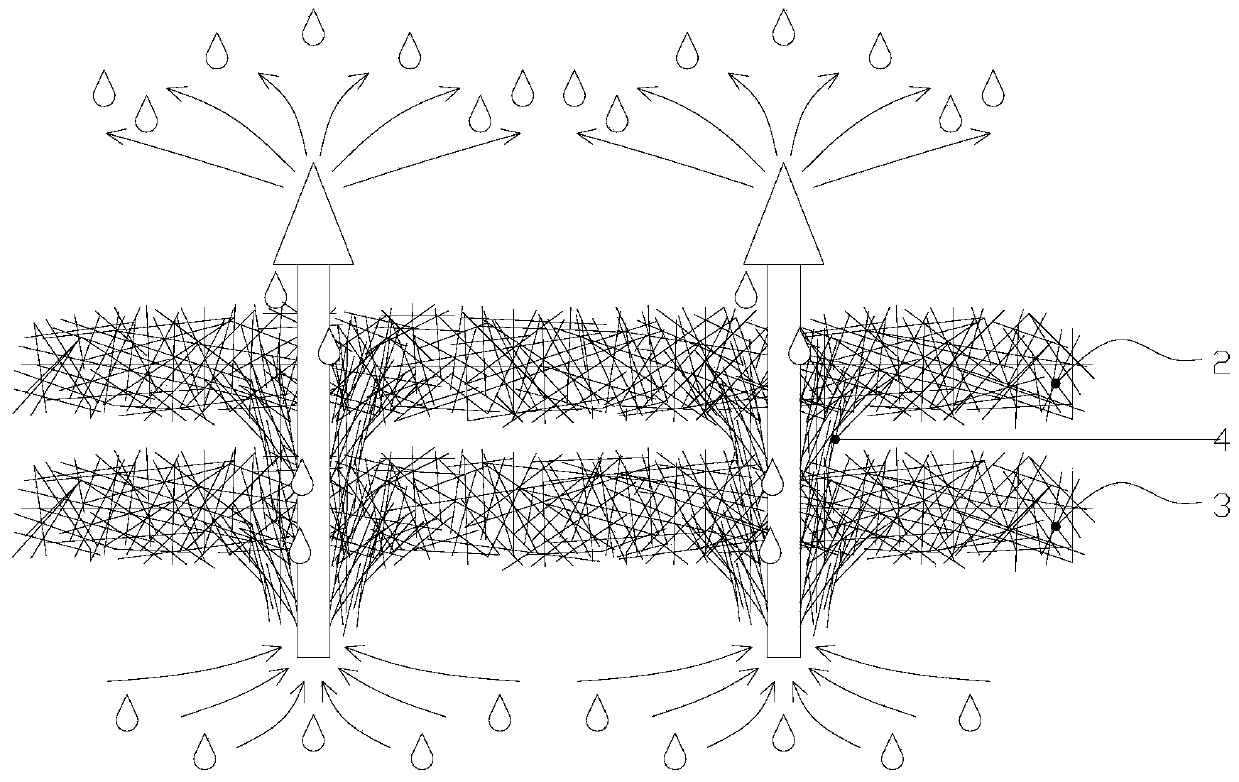

[0026] Select the viscose fiber with a fiber fineness of 1.5d and a fiber length of 38mm to be processed by acupuncture to a weight of 40g / m 2 Hydrophilic nonwoven batting layer 1. The cross-section polyester fiber with a fiber fineness of 1.68d and a fiber length of 38mm is selected and processed by acupuncture to a weight of 40g / m 2 Water-conducting nonwoven batting layer 2. Select polyester fibers with a fiber fineness of 3d and a fiber length of 64mm to be processed by acupuncture to a weight of 40g / m 2 Hydrophobic nonwoven batting layer 3. The specific preparation steps of the hydrophilic non-woven flake layer 1, the water-conducting non-woven flake layer 2 and the hydrophobic non-woven flake layer 3 are firstly to initially open the fibers through the coarse opener, and then pass them into the fine opener. The secondary opening is carried out, so that the large fiber clusters and blocks are torn into fiber bundles, and then the fiber bundles are combed into single fib...

Embodiment 2

[0028] Select bamboo fibers with a fiber fineness of 1.5d and a fiber length of 38mm to be processed by acupuncture to a grammage of 60g / m 2 Hydrophilic nonwoven batting layer 1. Select the Coolmax fiber with a fiber fineness of 1.68d and a fiber length of 38mm, which has a four-pipe hollow cross-section, and process it with a needle punching process so that the grammage is 50g / m 2 Water-conducting nonwoven batting layer 2. Select polyester fibers with a fiber fineness of 1.4d and a fiber length of 64mm to be processed by acupuncture to a weight of 50g / m 2 Hydrophobic nonwoven batting layer 3. Others are the same as embodiment one.

Embodiment 3

[0030] Select silk with a fiber fineness of 1.5d and a fiber length of 38mm to be processed by acupuncture to a weight of 60g / m 2 Hydrophilic nonwoven batting layer 1. Select Cooldry fiber with fiber fineness of 1.68d and fiber length of 38mm to be processed by needle punching process so that the grammage is 50g / m 2 Water-conducting nonwoven batting layer 2. The polypropylene fiber with a fiber fineness of 3d and a fiber length of 64mm is selected and processed by acupuncture to a weight of 30g / m 2 Hydrophobic nonwoven batting layer 3. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com