Fiber toning trial-production device

A fiber and mixing device technology, applied in the field of fiber spinning, can solve the problems of waste of manpower, physical and financial resources, difficulty in determining the fiber ratio, waste of raw materials, etc., to avoid waste of raw materials, reduce color difference, and ensure the uniformity of mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

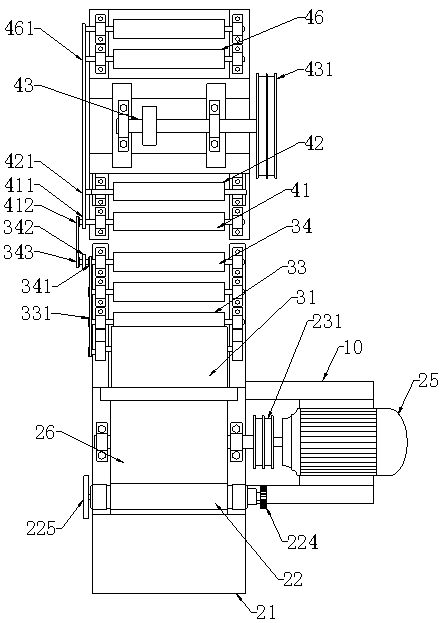

[0032] Such as Figures 1 to 4 As shown, a fiber toning trial production device includes a fixed seat 10, a mixing device 20, a transmission device 30 and a trial production device 40, and the mixing device 20, the transmission device 30 and the trial production device 40 are fixedly installed on the fixed seat 10. Said mixing device 20 is connected with the trial production device 40 through the transfer device 30;

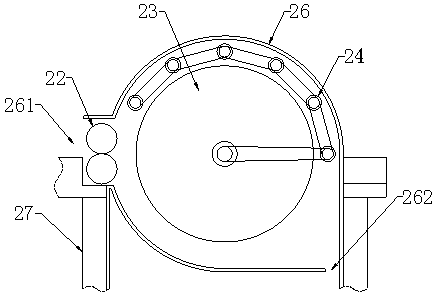

[0033] Described mixing device 20 comprises feeding platform 21, pressing roller group 22, main mixing roller 23, secondary mixing roller 24, first driving motor 25, shell 26 and mixing mounting frame 27, and described mixing mounting frame 27 is fixedly installed Above the fixed seat 10, the casing 26, the feeding platform 21 and the pressure roller group 22 are fixedly installed above the mixing installation frame 27, and the horizontal side of the casing 26 is provided with a feed port 261, which is opposite to the feed port 261 One side below is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com