A high-efficiency treatment system for waste tire rubber particles

A waste tire rubber and processing system technology is applied in the field of high-efficiency processing systems for waste tire rubber particles, which can solve the problems of uneven heating, insufficient raw material recycling rate, insufficient pyrolysis of waste tire particles, etc. The effect of improving energy utilization and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

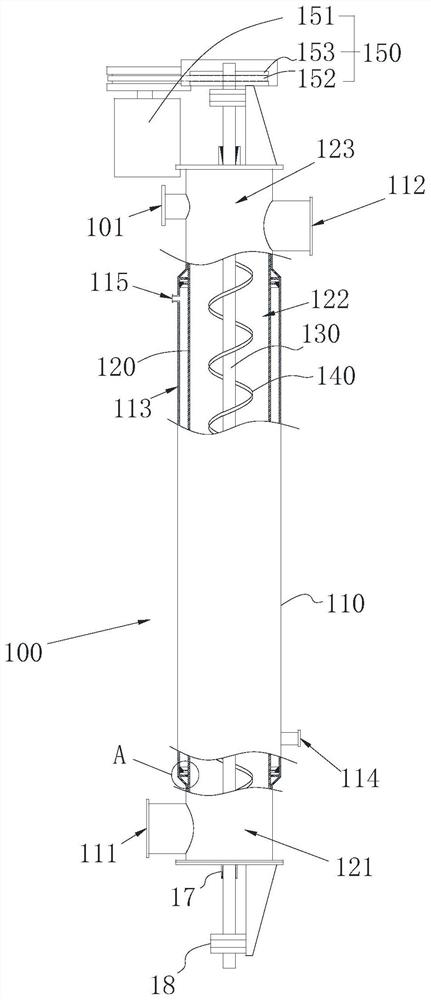

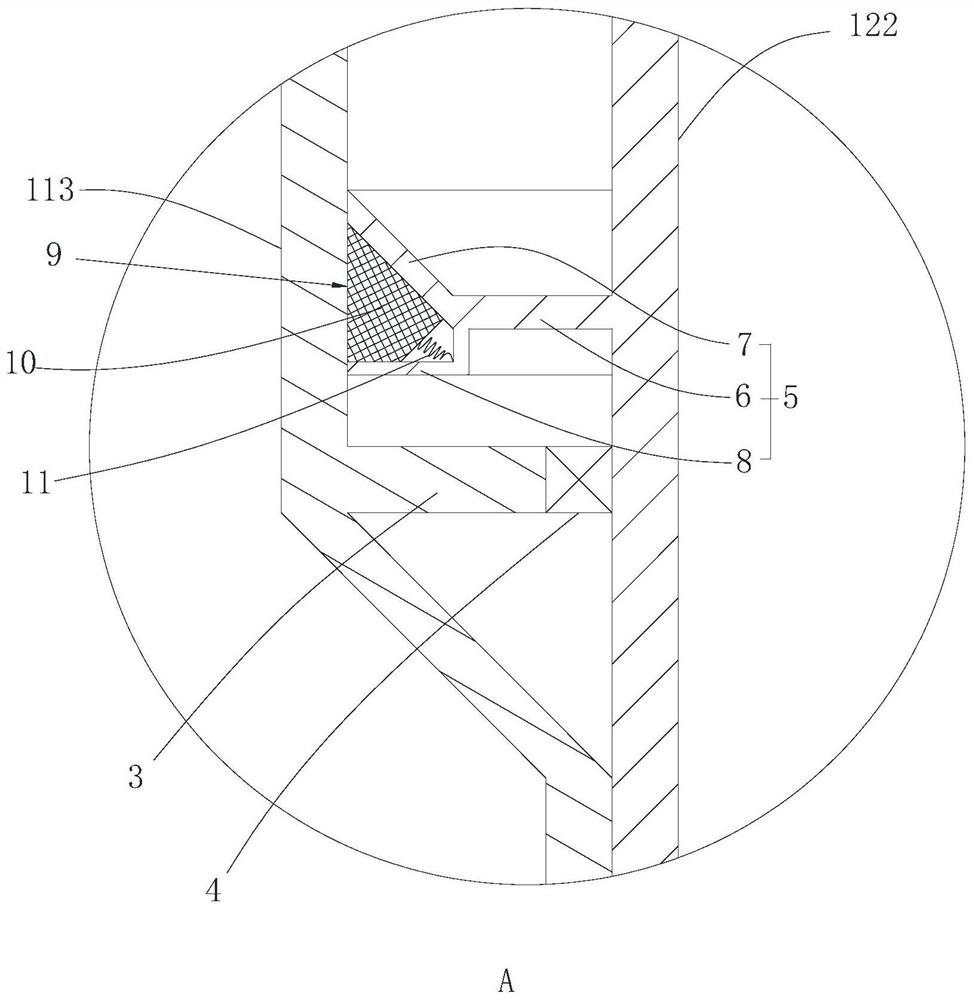

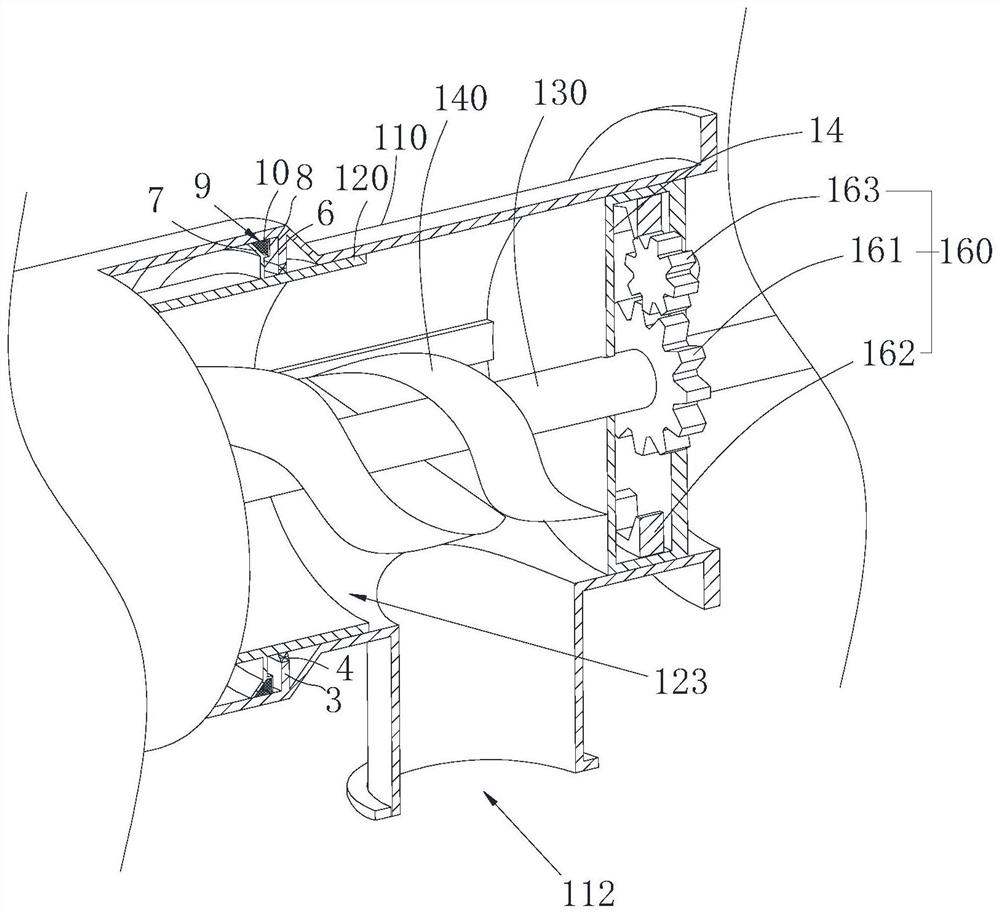

[0040] Embodiment 1, a high-efficiency treatment system for waste tire rubber particles:

[0041] as attached Figure 1~4 The high-efficiency treatment system for waste tire rubber particles shown includes a cracking furnace 100 , a molten salt combustion furnace 200 , an oil-gas separator 300 , a desulfurization tower 400 , an air tank 500 , an oil tank 600 , and a carbon black bin 20 . The molten salt combustion furnace 200 is used to heat the molten salt and supply the molten salt to the cracking furnace 100; The gas outlet 301 enters the gas tank 500 through the desulfurization tower 400, and the separated oil enters the oil tank 600 from the liquid outlet of the oil-gas separator 300; here, the gas in the gas tank 500 can be supplied to the molten salt combustion furnace 200 for recycling; The carbon black produced in the cracking furnace 100 directly enters the carbon black bin 20 .

[0042] Among them, an oil-gas condenser 19800 is connected between the oil-gas separa...

Embodiment 2

[0051] Embodiment 2, an efficient treatment system for waste tire rubber particles:

[0052] The difference between the second embodiment and the first embodiment is that there are several ribs 12 distributed on the inner surface of the material reaction tube 120 , and the length direction of the ribs 12 is arranged along the axial direction of the material reaction tube 120 . The length direction of the strip-shaped rib 12 is consistent with the conveying direction of the rubber particles. On the one hand, the resistance to the conveying of the rubber particles is small; More fully and evenly.

Embodiment 3

[0053] Embodiment 3, an efficient treatment system for waste tire rubber particles:

[0054] The difference between the third embodiment and the first embodiment is that the inner surface of the material reaction cylinder 120 has a number of protrusions 13 uniformly distributed, and the protrusions 13 are formed by extrusion from the outer surface of the material reaction cylinder 120 to the inner surface. On the one hand, the protruding part 13 can drive the rubber particles to move in the circumferential direction, and improve the mixing effect of the rubber particles; area, improve the heat conduction effect, and make the rubber particles in the cylinder more fully and evenly heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com