Light high-strength thin-wall cast-in-place concrete

A thin-walled structure, concrete technology, applied in the field of building materials, can solve problems affecting strength development, limiting organic components and expansion agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

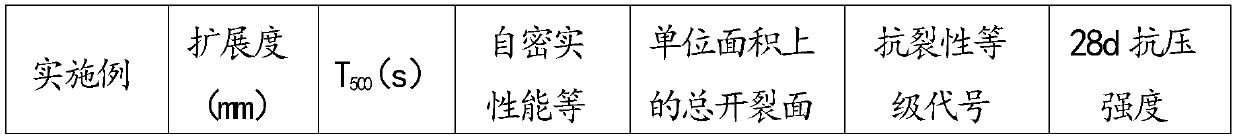

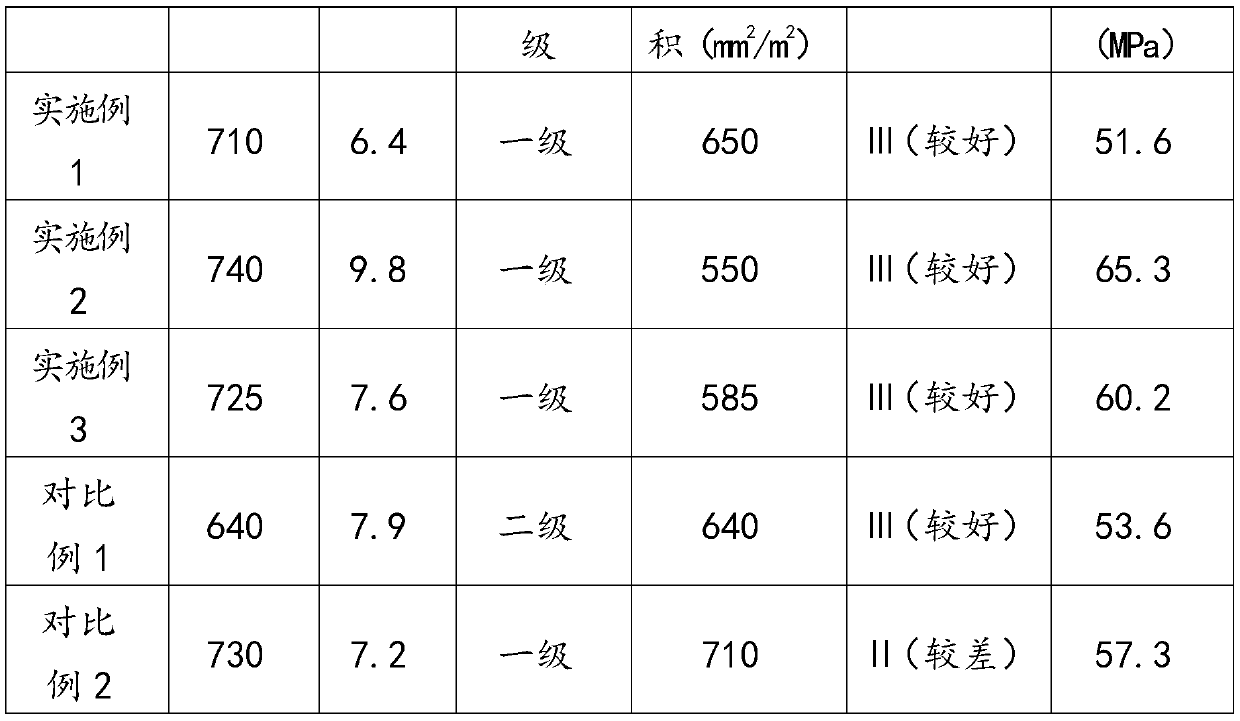

Examples

Embodiment 1

[0023] The embodiment of the present invention provides a light-weight, high-strength thin-walled cast-in-place concrete, which is composed of the following raw materials: 220 parts of cement, 150 parts of fly ash, 30 parts of silica fume, 80 parts of mineral powder, 900 parts of crushed stone, 800 parts of sand, 80 parts of FRP particles, 8 parts of admixture, 40 parts of shrinkage-reducing and anti-cracking material, and 150 parts of water.

[0024] In a specific embodiment, the cement is Washi P·O 42.5 ordinary Portland cement.

[0025] In a specific embodiment, the fly ash is Huadian high-quality Class I fly ash.

[0026] In a specific embodiment, SiO in silica fume 2 The content is 96%, and the specific surface area is 23200m 2 / kg.

[0027] In a specific embodiment, the ore powder is Xinyuan S95 ore powder.

[0028] In a specific embodiment, the gravel is Youkun 5mm-16mm continuous graded gravel, the maximum nominal particle size is ≤16mm, the crushing value is 9.0%,...

Embodiment 2

[0033] The embodiment of the present invention provides a light-weight, high-strength thin-walled cast-in-place concrete, which is composed of the following raw materials: 300 parts of cement, 120 parts of fly ash, 20 parts of silica fume, 60 parts of mineral powder, 820 parts of crushed stone, 640 parts of sand, 140 parts of glass fiber reinforced plastic particles, 12 parts of admixture, 80 parts of shrinkage-reducing and anti-cracking material, and 130 parts of water.

[0034] In a specific embodiment, the cement is Washi P·O 42.5 ordinary Portland cement.

[0035] In a specific embodiment, the fly ash is Huadian high-quality Class I fly ash.

[0036] In a specific embodiment, SiO in silica fume 2 The content is 96%, and the specific surface area is 23200m 2 / kg.

[0037] In a specific embodiment, the ore powder is Xinyuan S95 ore powder.

[0038] In a specific embodiment, the crushed stone is Youkun 5mm~16mm continuous graded crushed stone, the maximum nominal particle...

Embodiment 3

[0043] The embodiment of the present invention provides a light-weight, high-strength thin-walled cast-in-place concrete, which is composed of the following raw materials: 260 parts of cement, 135 parts of fly ash, 25 parts of silica fume, 70 parts of mineral powder, 860 parts of crushed stone, 720 parts of sand, 110 parts of FRP particles, 10 parts of admixture, 60 parts of shrinkage-reducing and anti-cracking material, and 140 parts of water.

[0044] In a specific embodiment, the cement is Washi P·O 42.5 ordinary Portland cement.

[0045] In a specific embodiment, the fly ash is Huadian high-quality Class I fly ash.

[0046] In a specific embodiment, SiO in silica fume 2 The content is 96%, and the specific surface area is 23200m 2 / kg.

[0047] In a specific embodiment, the ore powder is Xinyuan S95 ore powder.

[0048] In a specific embodiment, the crushed stone is Youkun 5mm~16mm continuous graded crushed stone, the maximum nominal particle size is ≤16mm, the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com