Ecological desilting system and method

An ecological and dredging vessel technology, applied in the direction of chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., can solve problems such as inability to respond, failure to achieve, etc., to improve filter press efficiency, The effect of increasing the processing capacity and meeting the requirements of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

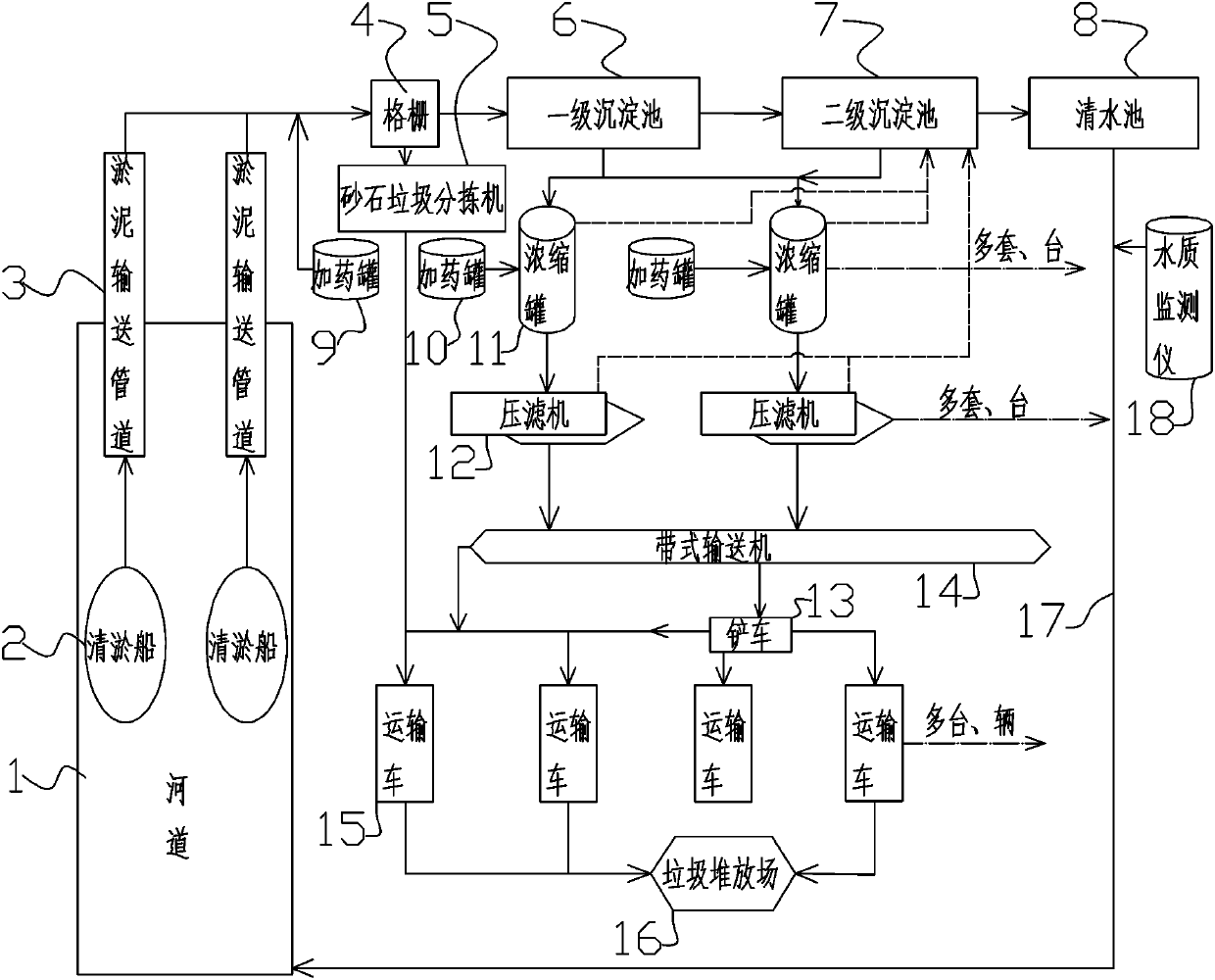

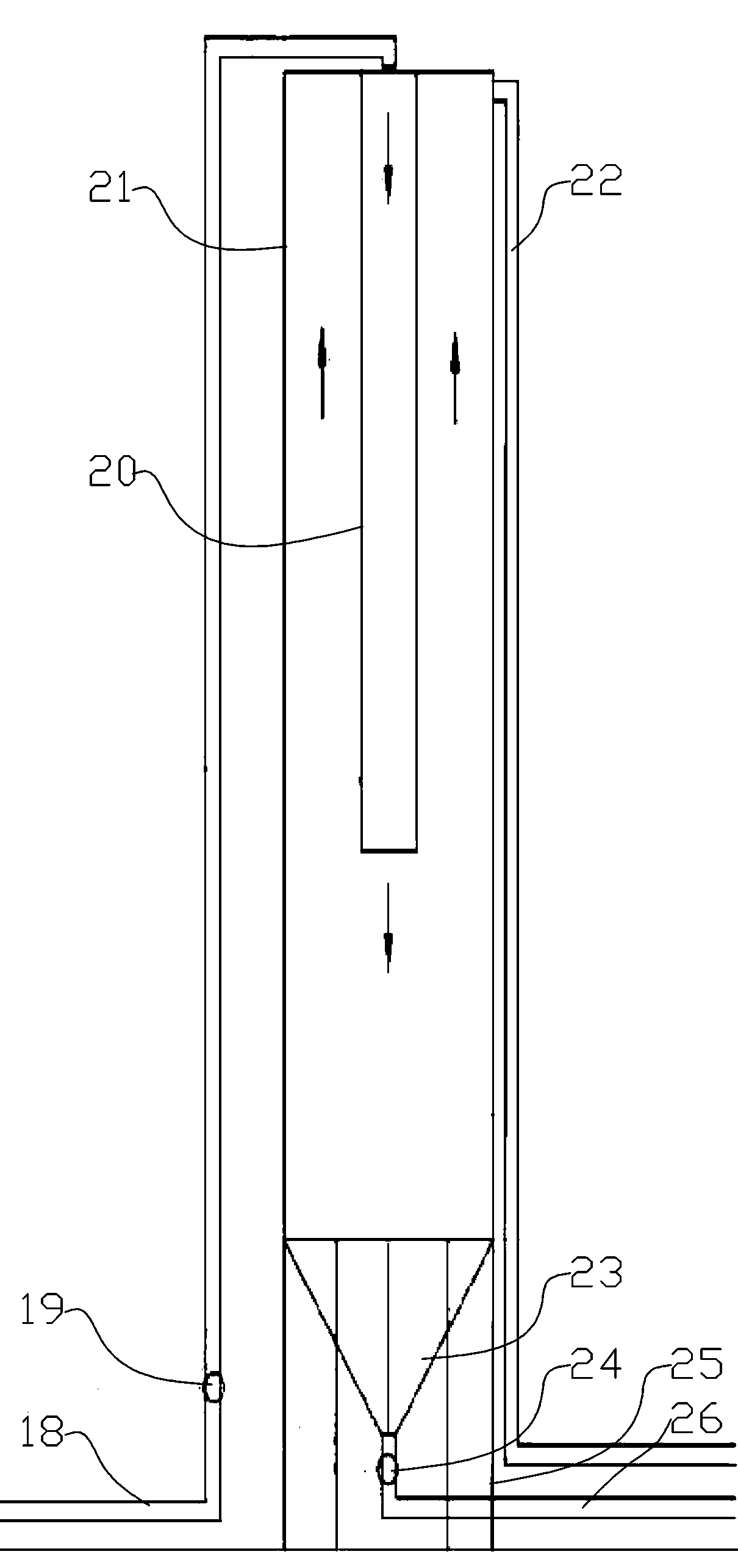

[0040] see figure 1 , an ecological dredging system, which includes a dredging ship 2 for sucking sludge inside a river channel 1, and the sludge outlet of the dredging ship 2 is connected to a grid 4 for dry-wet separation through a sludge conveying pipeline 3 , the leakage port of the grid 4 is connected with the primary sedimentation tank 6, the primary sedimentation tank 6 is connected with the secondary sedimentation tank 7, the sewage outlet of the primary sedimentation tank 6 and the secondary sedimentation tank 7 A plurality of concentration tanks 11 for sewage concentration are communicated respectively, and the bottom sewage outlet of the concentration tank 11 is connected with a filter press 12, and the dry mud outlet of the filter press 12 is connected with a belt conveyor 14, The filter press water outlet is connected to the secondary settling tank 7 through a pipeline, and the feeding end of the belt conveyor 14 is connected to a garbage dump 16 through a transpo...

Embodiment 2

[0051] In this embodiment, an actual engineering project of a certain river course is taken as an example for illustration.

[0052] 1. Project overview

[0053] The company won the bid for the fifth construction section of the ecological dredging project of the Xiaoqing River Jinan City Section (0+000~30+472).

[0054] For a long time, the Xiaoqing River, as the mother river of Jinan, has been polluted by industrial and domestic sewage discharged from surrounding industrial and residential areas for a long time, resulting in the accumulation of silt at the bottom, which seriously affects the surrounding environment. It cannot be drained during the rainy season, endangering the health of residents on both sides of the river. In order to effectively improve the ecological environment of the river waters, restore its ecological functions and improve the flood discharge capacity, it is urgent to carry out comprehensive treatment of the river. This dredging is a measure for the im...

Embodiment 3

[0088] The method for carrying out river channel cleaning by the ecological dredging system comprises the following steps:

[0089] Step1: The dredging ship 2 is equipped with a sewage suction winch, and the sludge at the bottom of the river channel 1 is transported to the solid-liquid separation grid 4 through the sludge conveying pipeline 3 for preliminary separation, and then the large sandstone and garbage in the sludge are initially separated Separation; wherein in the conveying process, the flocculant is added to the inside of the sludge conveying pipeline 3 through the first dosing box 9 for preliminary flocculation;

[0090] Step2: The solid waste separated by the grid 4 will be transported to the gravel waste sorting machine 5 for sorting, and then transported to the waste dump 16 by the transport vehicle 15; and the separated sludge will be transported To the primary sedimentation tank 6 for precipitation;

[0091] Step3: The primary sedimentation tank 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com