Automatic balancing system for internal centering of large rotating moving parts

A technology of rotating motion and automatic balancing, which is applied in the directions of transportation, packaging, loading/unloading, etc., and can solve the problem of insufficient guarantee of the space accuracy of the rolling surface of the rolling ring raceway, wear and damage of the rolling surface of the rolling ring and its supporting rollers, and failure Solve problems such as the force on the rolling surface of the raceway of the rolling ring, and achieve the effects of simplifying the installation, calibration and adjustment process, balancing the force, and simplifying the installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

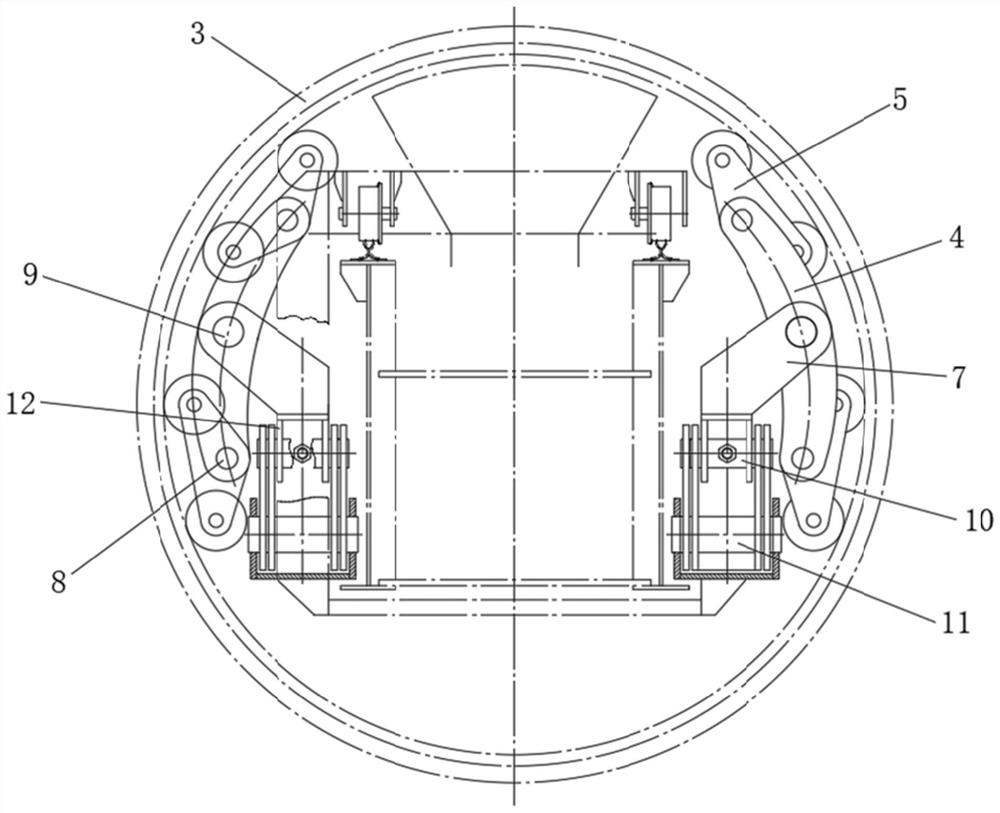

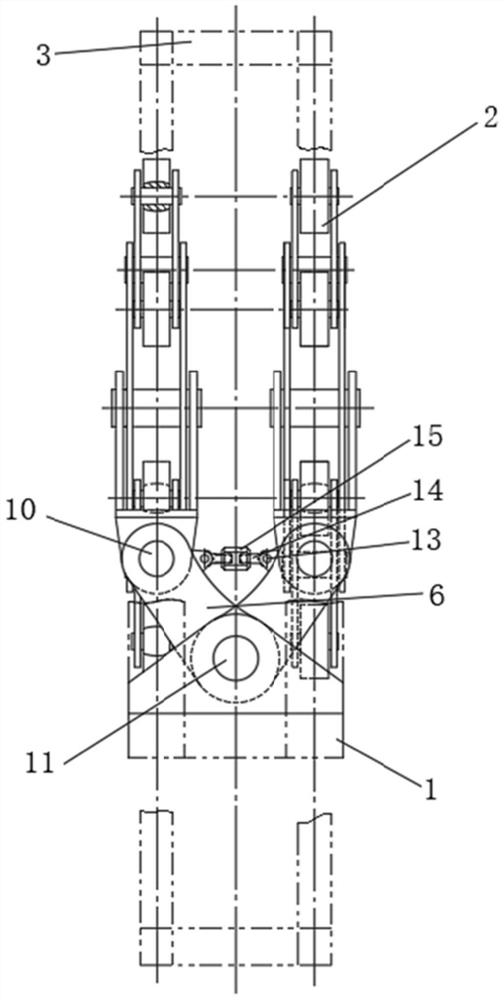

[0030] figure 1 and figure 2 It shows an embodiment of the automatic balancing system used in the centering of large rotating parts according to the present invention. The balancing system is provided with a base 1 and a radial balancing mechanism, and the radial balancing mechanism is installed on the base 1. The base 1. Fixed on the frame of the rotating moving part, the radial balance mechanism is provided with at least two groups of radial balancing components, and the radial balancing mechanisms are respectively located on both sides of the raceway of the rotating moving part; the radial balancing component Including radial balance pendulum 4 and support roller 2, described support roller 2 comprises at least two groups, each end of described radial balance pendulum 4 is provided with at least one set of support roller 2, and described support roller 2 is installed in radial direction On the balance pendulum 4 , and the support roller 2 can rotate relative to the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com