Reinforced temperature measurement optical cable

An enhanced, optical cable technology, applied in optics, light guides, thermometers, etc., can solve the problems of unfavorable temperature rapid perception, unfavorable temperature rapid conduction, temperature timeliness lag, etc., and achieve the effect of simple structure, rapid temperature conduction and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

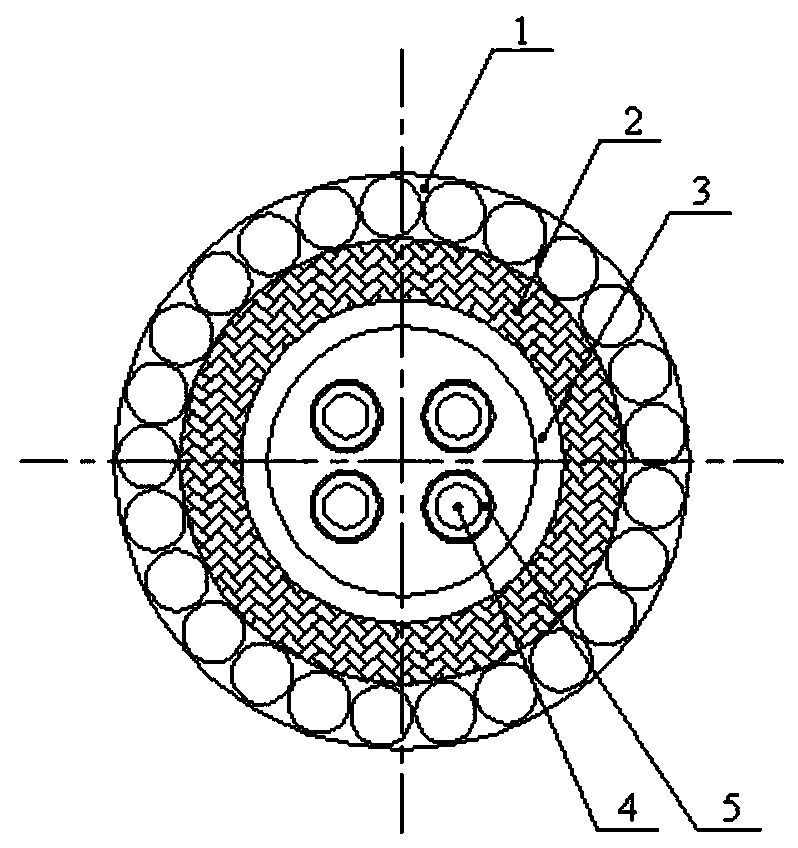

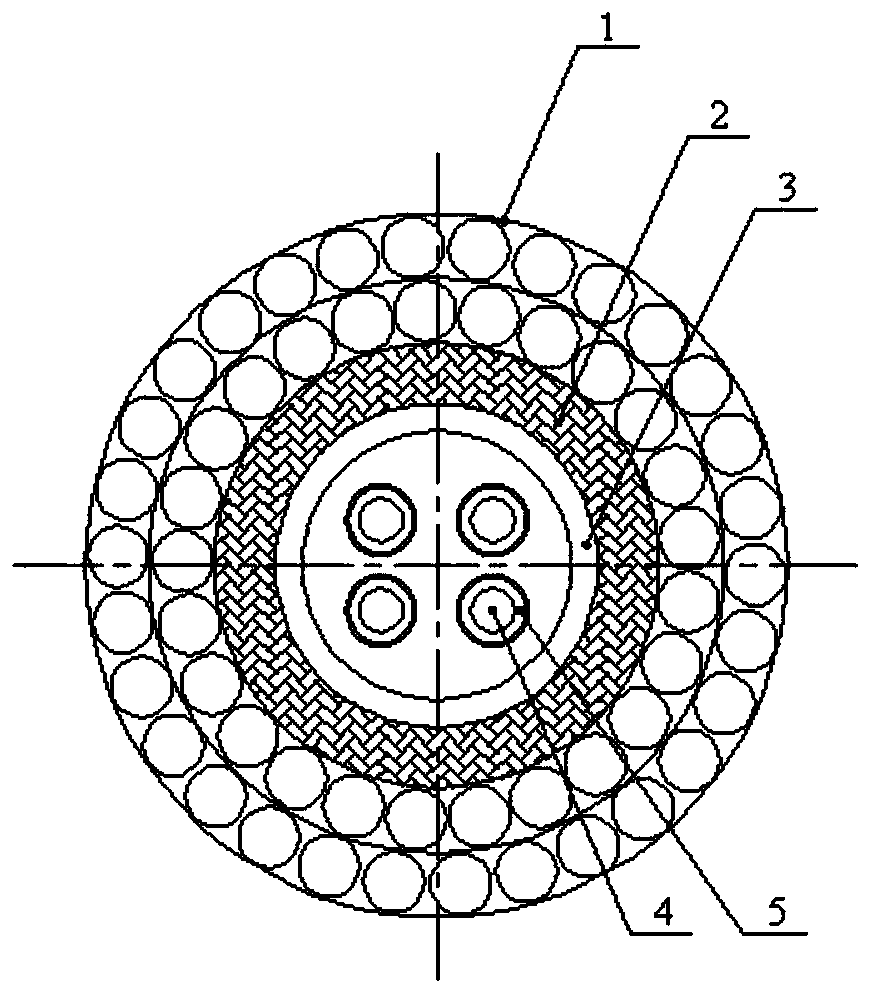

[0018] A reinforced temperature measurement optical cable, such as figure 1 As shown, the center is one or more bare optical fibers 4. If necessary, a tight jacket layer 5 can be added outside the bare optical fiber as the primary protection for the optical fiber. The type of optical fiber can be single-mode optical fiber or multi-mode optical fiber.

[0019] A metal tube is used as the armor layer 3 on the outer layer of the optical fiber bundle to provide compression protection for the optical fiber and provide a certain tensile force. The metal tube can be manufactured using a variety of materials or processes, for example, one is made of stainless steel The other is to use stainless steel welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com