Automated gear case fault diagnosis method based on neural network and characteristic frequency band

A technology of fault diagnosis and characteristic frequency bands, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve the problems of time-consuming and labor-intensive, high threshold for ordinary technicians, reduce workload, facilitate engineering promotion, and widely powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

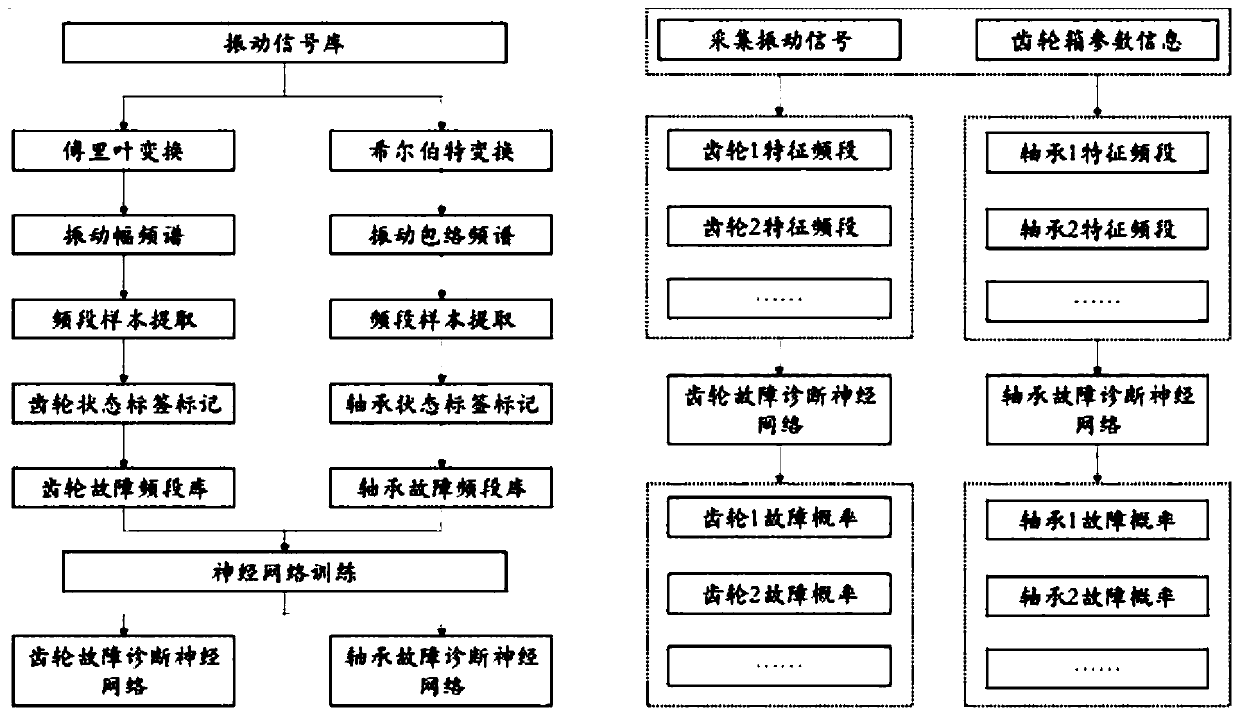

[0042] see figure 1 , an automatic fault diagnosis method for gearboxes based on neural networks and characteristic frequency bands. Gearbox faults generally include gear faults and bearing faults, and bearing faults include inner rings, outer rings, rolling elements, and cages. , including the following steps:

[0043] Step 1. Collect signals and build a signal library:

[0044] The vibration acceleration signal collected by the acceleration sensor is used on the casing of the sample gearbox, and filtered. The vibration acceleration signal includes the vibration signal of the gear / bearing when there is / is not faulty, and the signal library is constructed.

[0045] Step 2, signal processing:

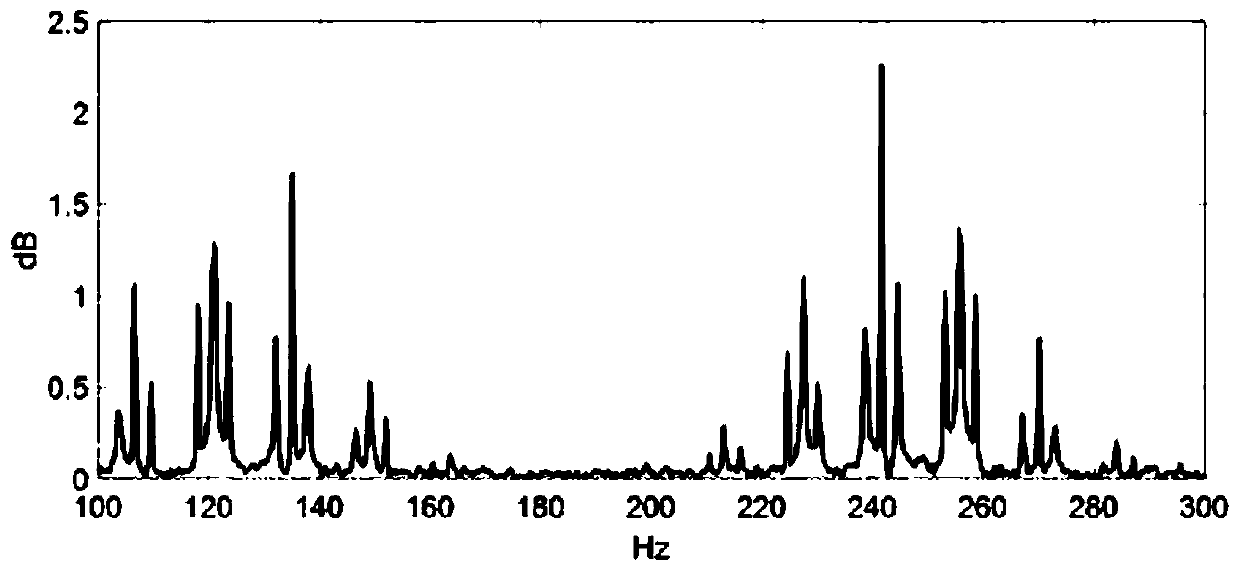

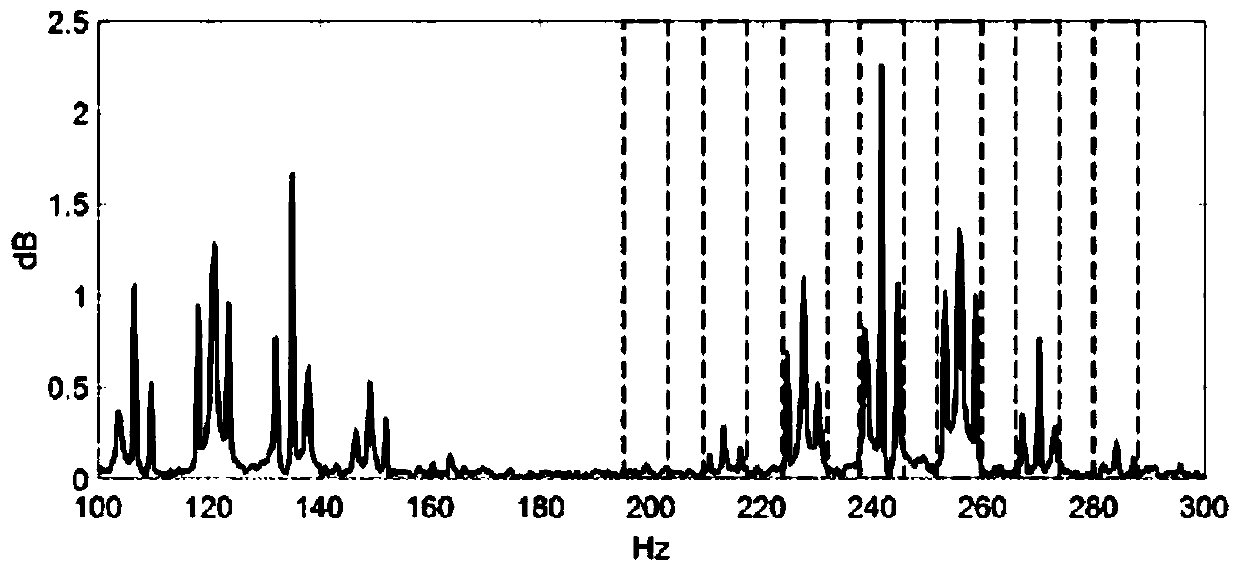

[0046] Fourier transform and Hilbert transform are respectively performed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com