A synchronous removal of h in gas 2 s and so in the flue gas x with no x Methods

A gas and flue gas technology, applied in the field of gas and flue gas pollutant control, can solve problems such as difficulty in absorbing liquid regeneration, and achieve the effects of significant energy saving and environmental protection benefits, low operating costs, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

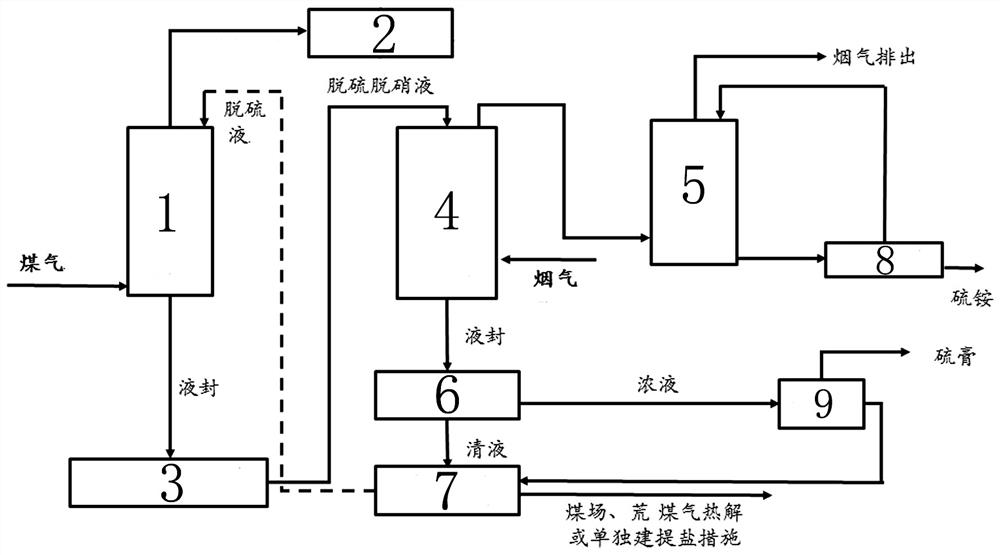

[0024] Embodiment 1: A kind of synchronous removal of H in gas 2 S and SO in flue gas x with NO x The method, described method is coal gas desulfurization and flue gas desulfurization denitrification process; Concrete steps are:

[0025] Coal gas desulfurization process: Coal gas A cooled to 35°C enters from the bottom of the gas desulfurization tower, and the H in gas A2 S concentration is 6g / m 3 , the desulfurization liquid uses ammonia as the alkali source, HPF as the desulfurization catalyst, the desulfurization liquid B is sprayed from the top of the gas desulfurization tower, the gas A and the desulfurization liquid B are in countercurrent contact and the H in the gas is removed 2 S, absorbing H through desulfurization liquid B 2 The gas A obtained after S is discharged from the top of the desulfurization tower, and the gas goes through the above process, and its H 2 S concentration reduced to 15mg / m 3 , the purified gas enters the follow-up ammonium sulfate system;...

Embodiment 2

[0027] Embodiment 2: A kind of synchronous removal of H in coal gas 2 S and SO in flue gas x with NO x The method, described method is coal gas desulfurization and flue gas desulfurization denitrification process; Concrete steps are:

[0028] Coal gas desulfurization process: H 2 S concentration is 10g / m 3 Coal gas A at a temperature of 40°C enters from the bottom of the gas desulfurization tower, and desulfurization liquid B is injected from the middle and upper part of the gas desulfurization tower. Desulfurization liquid B uses sodium carbonate as an alkali source and a complex iron desulfurization catalyst. B countercurrent contact and removal of H in the gas 2 S, absorbing H through desulfurization liquid B 2 The gas A obtained after S is discharged from the top of the desulfurization tower and enters the gas user. The H in the gas after desulfurization 2 S concentration is 12mg / m 3 ; absorb H 2 The desulfurized liquid B after S is discharged from the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com