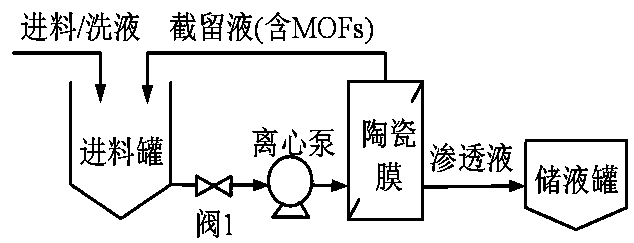

A process for functionalized MOFs adsorbent to enhance ceramic membrane separation

A ceramic membrane and adsorbent technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high maintenance and operation costs, low adsorption capacity, easy pollution, etc. problems, to reduce the risk of entering the ecosystem, realize the regeneration cycle, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Electroplating industrial wastewater contains low-concentration, highly toxic mixed heavy metal ions copper (Cu) and nickel (Ni), the concentrations are 25mg / L and 20mg / L respectively, the content of amino-functionalized MOFs is 1g / L, the control pressure is 0.1MPa, and the temperature is 20 ℃, ceramic membrane pore size 200nm, cross-flow velocity 4m / s, permeate volume 600L / m 2 / h, pH=3~6, the rejection rate of MOFs is 100%, the removal rate of copper and nickel ions is 100%, and the adsorption capacity of MOFs for copper and nickel ions is as high as 60mg / g. Adjust the pH to the neutral range after adsorption, MOFs are 100% intercepted, but copper ions are desorbed from the MOFs adsorbent into the solution, and eluted with pure water to obtain copper ion solution and Ni-MOFs solution, then adjust the pH To the alkaline range, nickel ion solution and MOFs solution are obtained, and the heavy metal ion products copper and nickel are respectively obtained by extraction, w...

Embodiment 2

[0030] In the analytically pure heavy metal ion solution of lead nitrate, the concentration is 30mg / L, pH=7~8, the content of amino-functionalized MOFs is 0.1g / L, the pore size of the ceramic membrane is 50nm, the control pressure is 0.15MPa, the temperature is 40°C, and the cross-flow velocity is 6m / s, permeation flux 770L / m 2 / h, the retention rate of MOFs is 100%, the removal rate of lead ions is close to 100%, and the adsorption capacity of MOFs to lead ions is as high as 300mg / g. After adsorption, the pH is adjusted to the acidic range, and the retention rate of MOFs is still 100%, but the lead ions are desorbed from the MOFs adsorbent into the solution, and eluted with pure water to obtain lead ion solution and MOFs solution, cooling and crystallization, and the product lead The purity of the salt is 99%, the yield is 90%, and the obtained MOFs can be recycled.

Embodiment 3

[0032] Industrial wastewater containing heavy metal ions cadmium, the concentration is 1.1μg / L, the content of amino-functionalized MOFs is 0.001g / L, the control pressure is 0.2MPa, the temperature is 60°C, the pore size of the ceramic membrane is 20nm, the cross-flow velocity is 2m / s, and the permeate volume is 300L / m 2 / h, pH=5~6, the interception rate of MOFs is 100%, the removal rate of cadmium ions reaches 100%, and the adsorption capacity of MOFs to cadmium ions is as high as 30mg / g. After adsorption, adjust the pH to the neutral range, MOFs are still 100% intercepted, but cadmium ions are desorbed from the MOFs adsorbent into the solution, and eluted with pure water to obtain cadmium ion solution and MOFs solution, and the heavy metal ion product cadmium is obtained by extraction , the yield is 90%, and MOFs are obtained at the same time, which can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com