One-touch reinforcing bar coupler

A joint, one-touch technology, applied in building components, building reinforcements, structural elements, etc., can solve the problems of increased slippage of steel bars and weak holding force, so as to improve structural rigidity, improve assembly, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

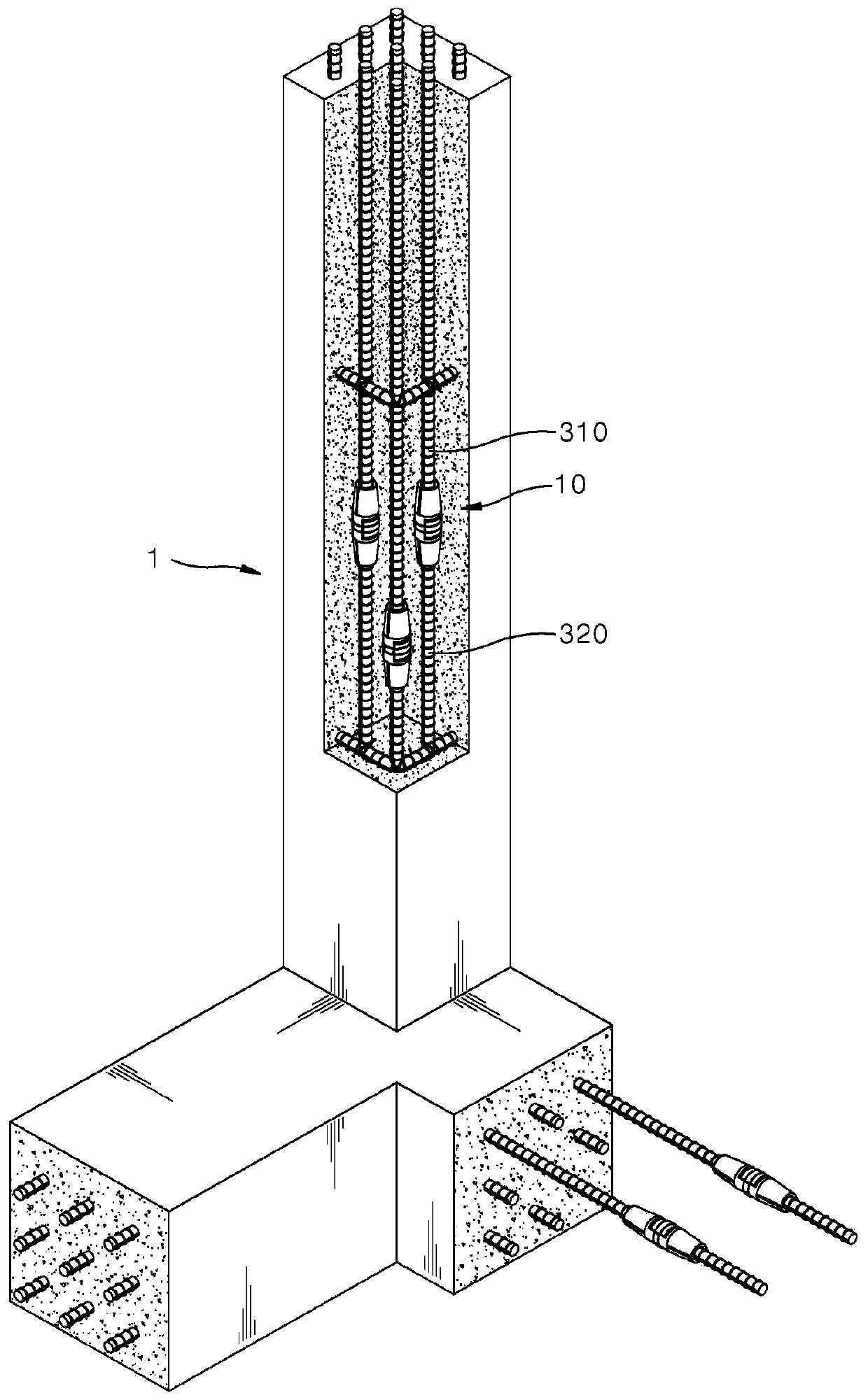

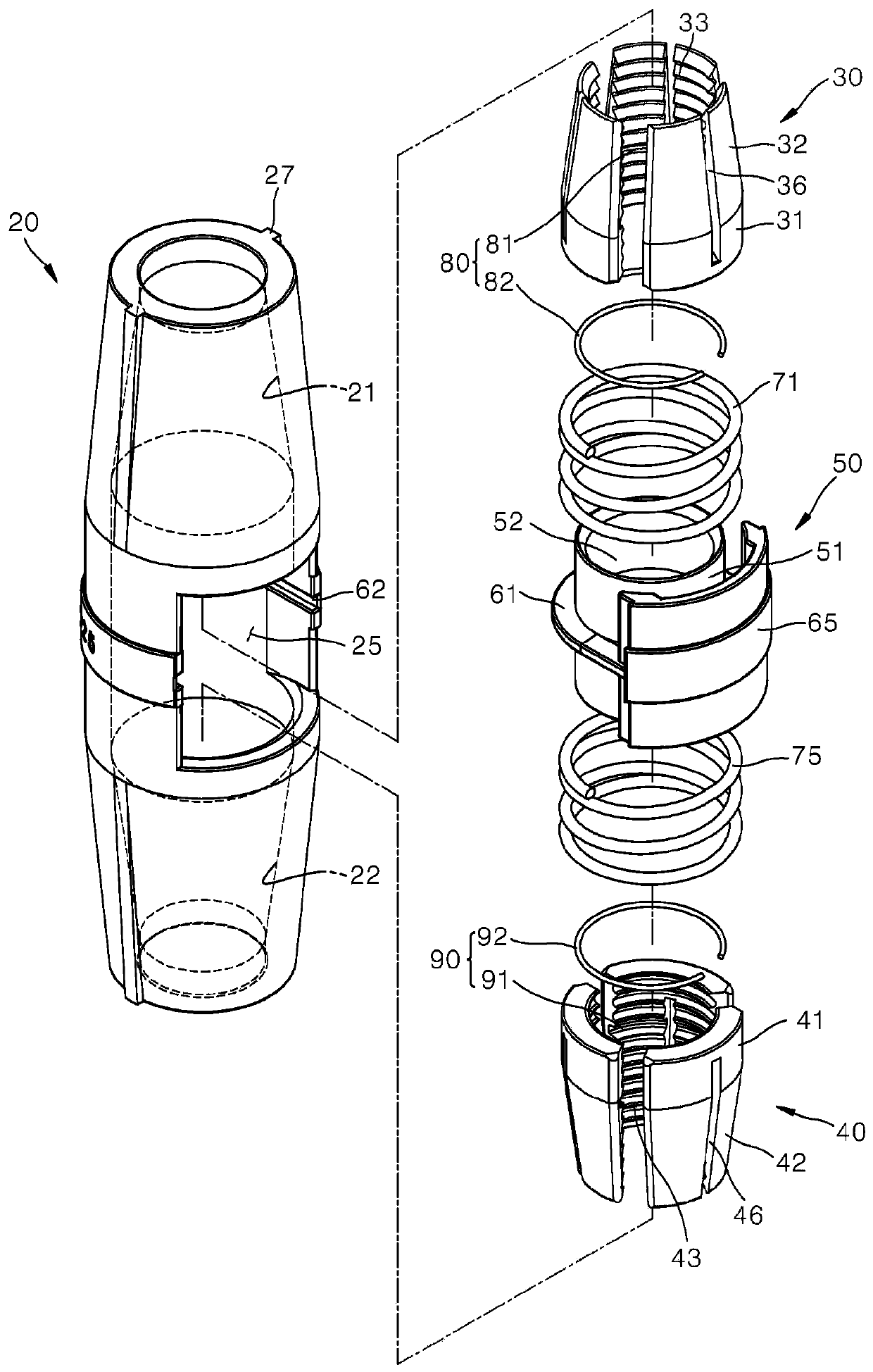

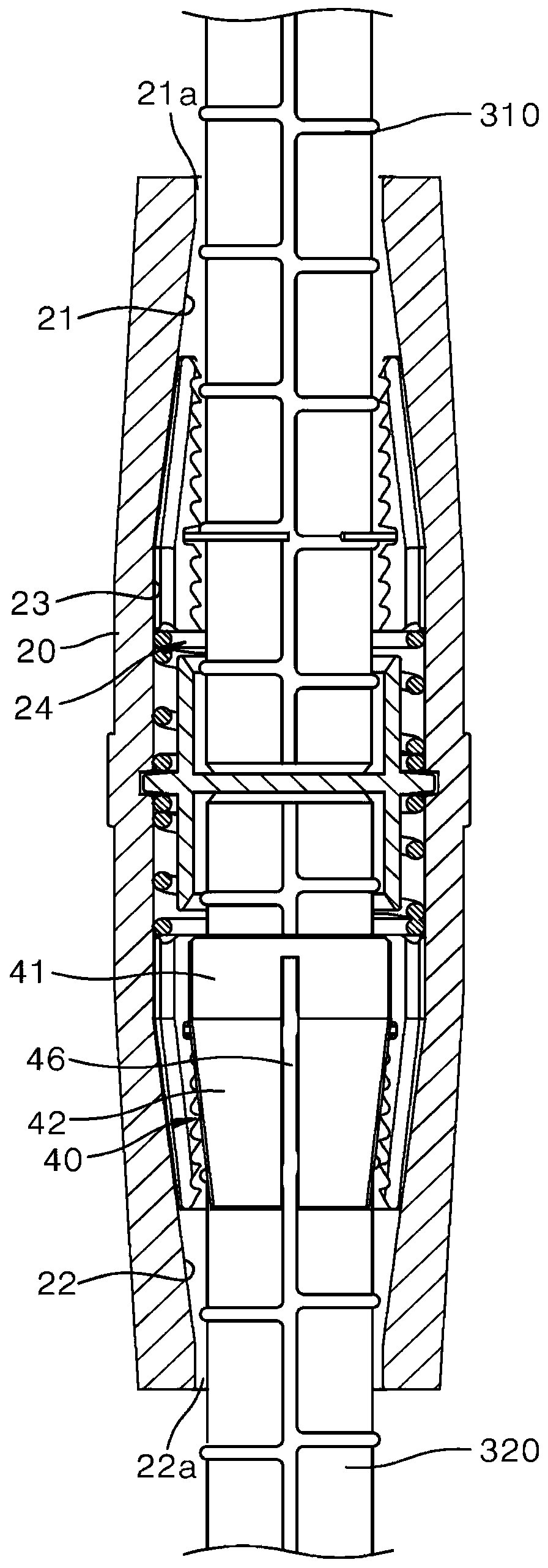

[0046] Figure 1 to Figure 8 An embodiment of a one-touch rebar coupling according to the invention is shown in .

[0047] Referring to the accompanying drawings, a one-touch steel bar coupling 10 according to the present invention is used to connect steel bars to each other when reinforcing bars in the construction of civil or concrete buildings 1, and has a coupling body 20, wherein the coupling body 20 forms There is a hollow part 24 with a first tapered part 21 and a second tapered part 22, the first tapered part 21 and the second tapered part 22 are used to insert the first steel bar 310 and the second steel bar 310 to be connected from both sides. The first insertion port 21a and the second insertion port 22a side of the reinforcement bar 320 are gradually expanded, and the component input opening 25 is formed on the outer peripheral surface of the coupling body 20 . The coupling body 20 has a first tightening unit 30 and a second tightening unit 40, wherein the first t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap