Communication combiner automatic debugging system

An automatic debugging and combiner technology, which is applied in the field of communication combiners to achieve the effects of improving stability, improving debugging accuracy and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

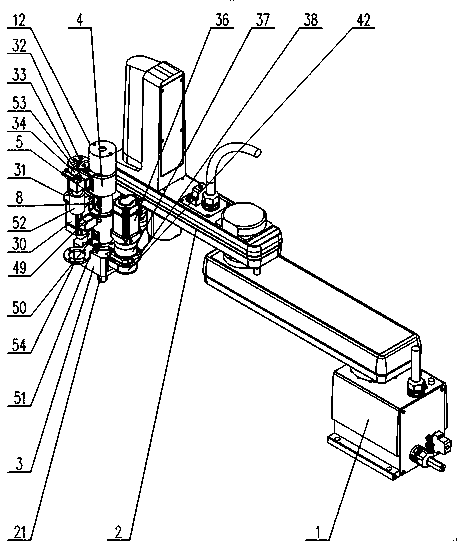

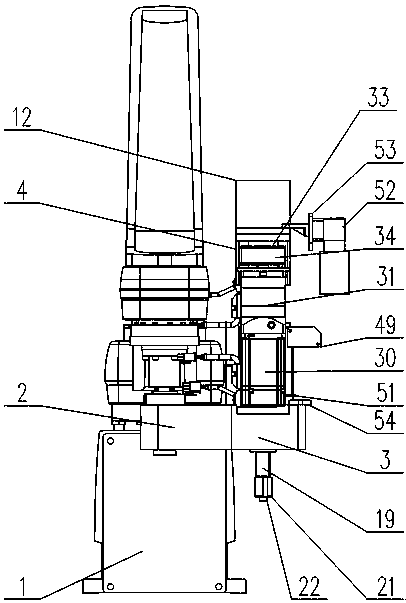

[0054] Such as Figure 1-Figure 15 As shown, the communication combiner automatic debugging system includes a robot 1 and a debugging device fixed on the control end of its mechanical arm 2. The debugging device includes a bracket, which rotates the screw adjustment assembly arranged on the bracket and driven by the first drive assembly to rotate. The nut adjustment assembly is set on the bracket, sleeved on the screw adjustment assembly, and driven by the second drive assembly. The first drive assembly is fixed on one side of the bracket, and its output shaft is located at the top, and through the reversing A transmission mechanism is used to drive the screw adjustment assembly to rotate, and the first drive assembly and the second drive assembly are alternately distributed in the circumferential direction of the screw adjustment assembly.

[0055] The reversing transmission mechanism can adopt a synchronous belt transmission mechanism, a bevel gear transmission mechanism, a ...

Embodiment 2

[0058] This embodiment is based on Embodiment 1, and describes the specific implementation structure of the bracket.

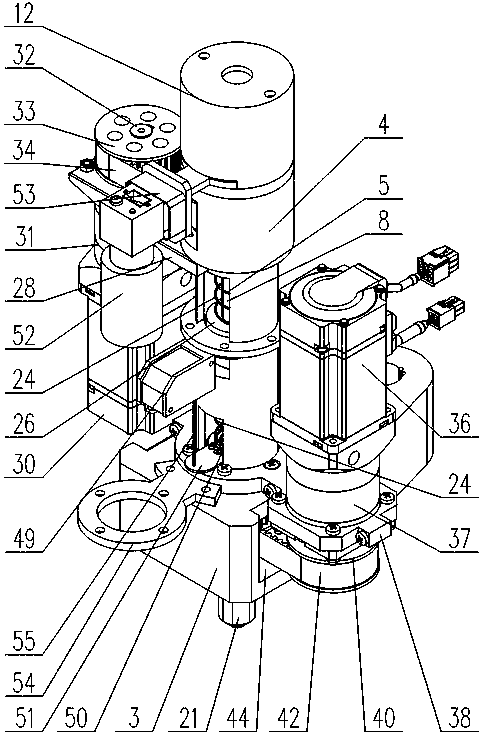

[0059] In the present invention, if image 3 with Figure 4 As shown, the support includes a base 3 fixed on one side of the manipulator 2 control end and a column 4 vertically fixed on the upper surface of the base 3, the column 4 is preferably fixed on the free end of the base 3, and the peripheral wall of the column 4 The bottom side of the bottom side protrudes outward into a flange, and the bolt is threaded with the base 3 after passing through the flange, so that the column 4 is detachably fixed on the base 3; the column 4 is provided with a through hole A6, and the through hole A6 The axis coincides with the axis of the column 4; the base 3 is provided with a through hole B7 coincident with the axis of the through hole A6;

[0060] Both the screw adjustment assembly and the nut adjustment assembly are rotatably fixed in the through hole A6, and their ...

Embodiment 3

[0063] This embodiment is based on the second embodiment, and describes the specific implementation of the screw adjustment assembly and the nut adjustment assembly.

[0064] The screw adjustment assembly includes a spline shaft A8 whose axes coincide with each other, a spline shaft sleeve A9, a coupling 10, a screwdriver rod 11 and a return spring, and the spline shaft sleeve A9 is sleeved on the spline shaft A8 , and is fixed in the through hole A6 by bearing rotation; the bottom end of the spline shaft A8 passes through the spline sleeve A9 and is connected with the top of the screwdriver rod 11 through the coupling 10, and the screwdriver rod 11 The bottom end is the bit, which is the adjustment end of the screw adjustment assembly, and it passes through the through hole B7; the return spring is sleeved on the spline shaft A8, and the screwdriver rod 11 moves upward relative to the spline shaft sleeve A9 , the return spring is in a compressed state.

[0065] The nut adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com