Hydrogen fuel cell stack assembling device

A fuel cell stack and assembly device technology, which is applied in the field of battery stacks, can solve problems such as unsatisfactory performance and lifespan reduction of the stack, and achieve the effects of ensuring success rate, improving assembly efficiency, and ensuring performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

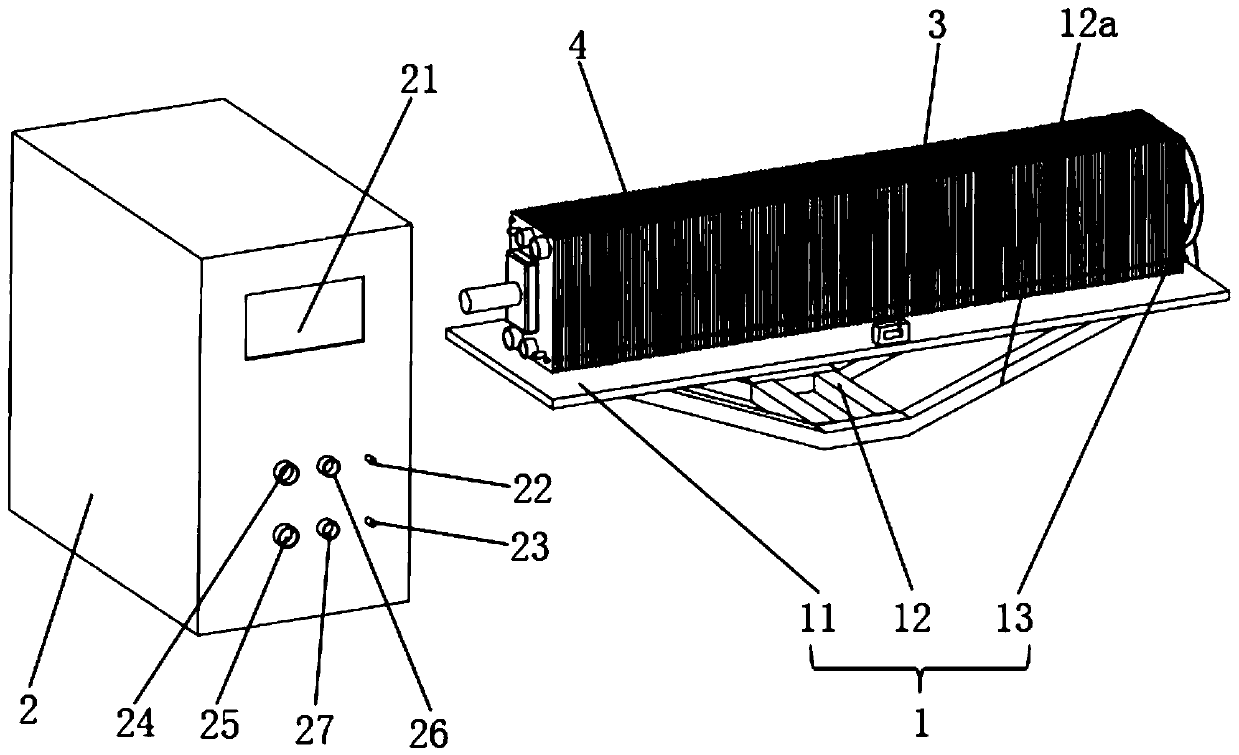

[0017] Please refer to Figure 1-Figure 3 , the embodiment of the present invention provides a hydrogen fuel cell stack assembly device, including a stack assembly platform 1 , an air tightness tester 2 and an angle tester 3 .

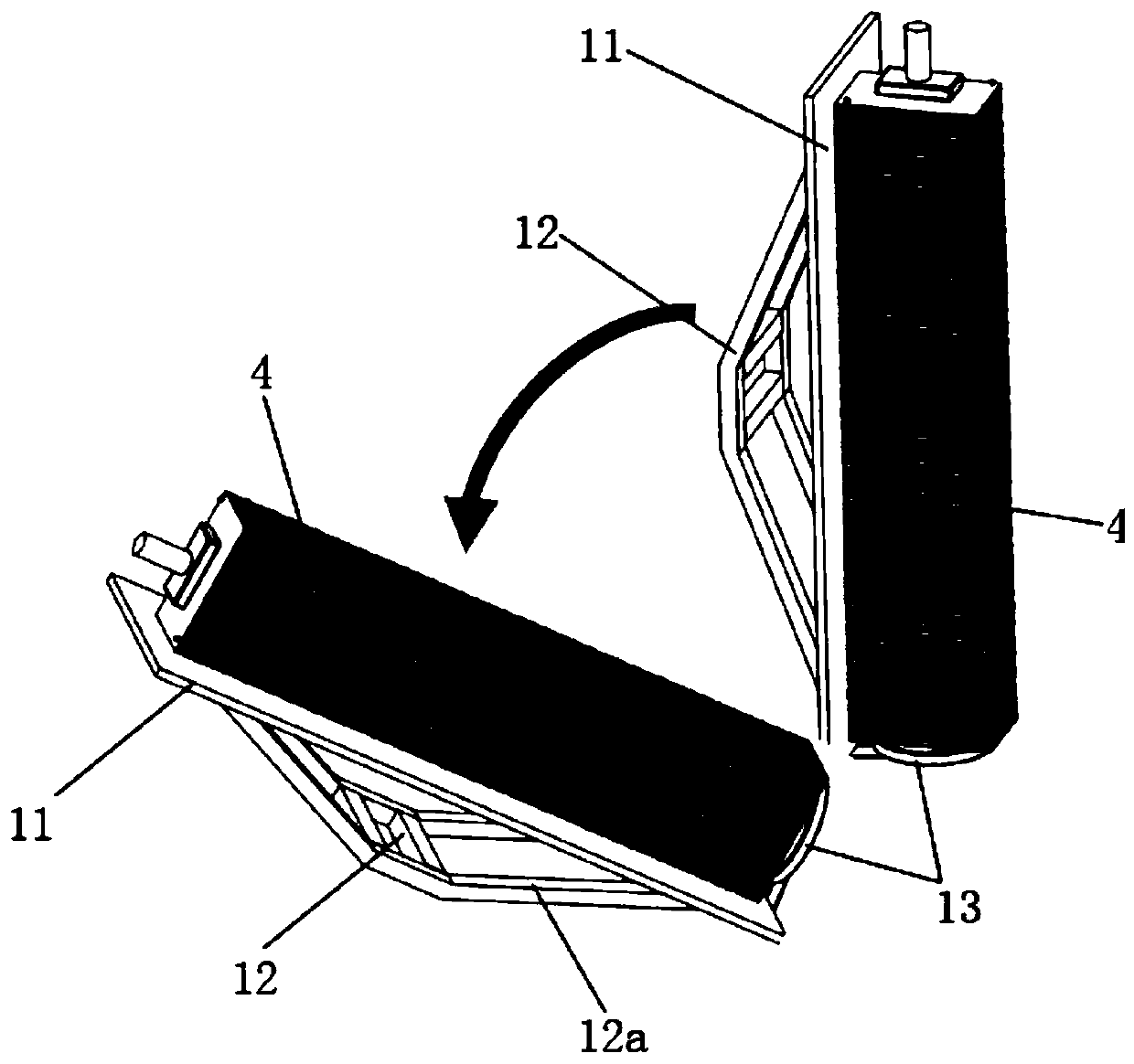

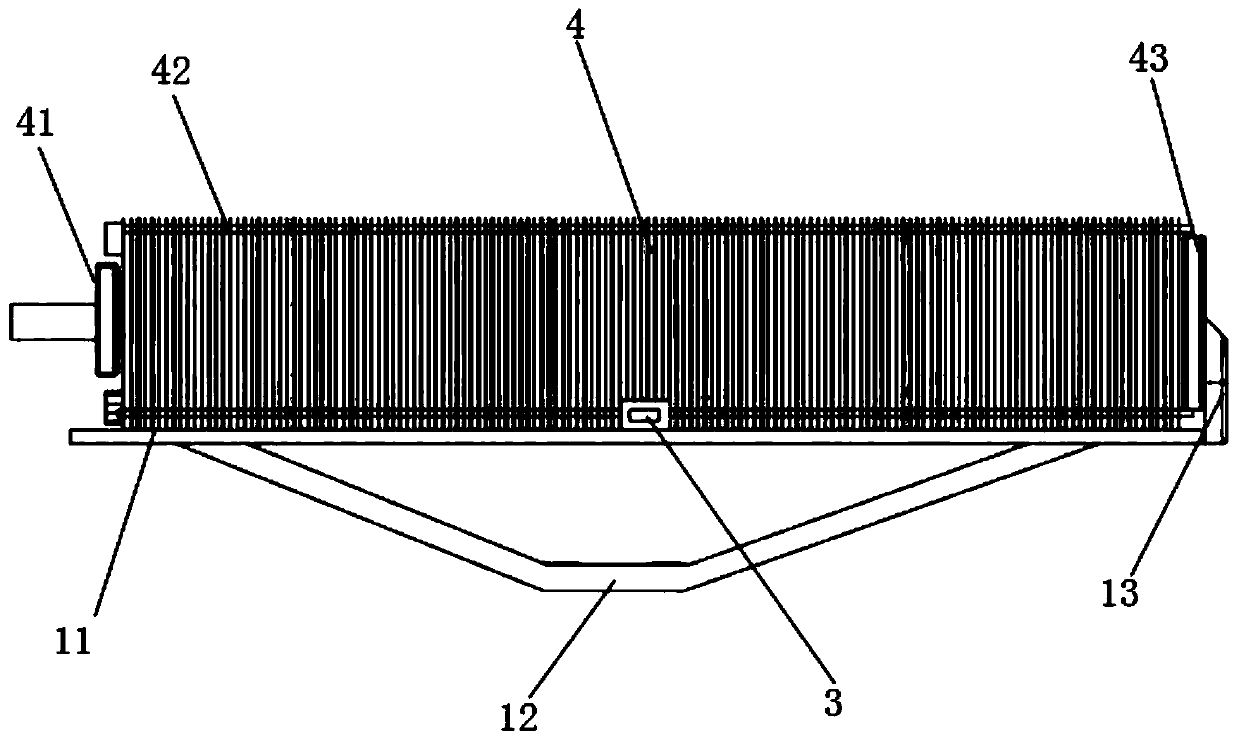

[0018] The stack assembly platform 1 includes a support plate 11, a bracket 12 and a pressure bearing plate 13, the support plate 11 is used to place the battery stack 4, and the front and rear ends of the support plate 11 correspond to the sides of the battery stack 4 respectively. The drive end plate 41 and the pressure end plate 43, the transverse section of the support 12 is trapezoidal and its lower bottom is fixedly installed on the lower surface of the support plate 11, the support 12 is provided with a hand-held tension r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com