Full-face tunnelling machine cutter arrangement design method based on stratum conditions

A full-face tunnel boring machine and design method technology, applied in mining equipment, earthwork drilling, instruments, etc., can solve the problem of insufficient certainty of the solution results, no quantitative calculation of the arrangement of the cutters, and no consideration of the rock-breaking efficiency of the cutters Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

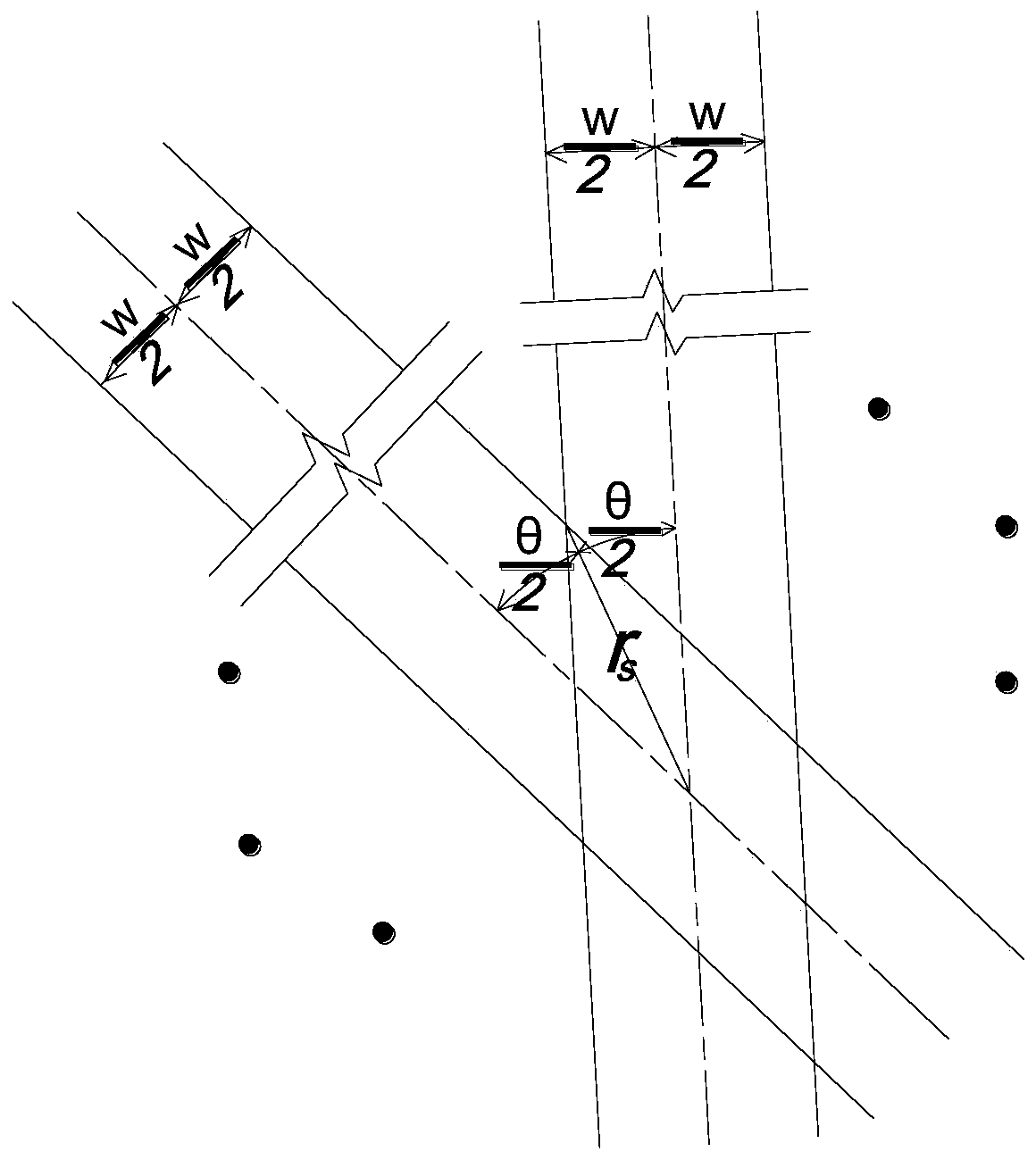

[0182] The face of the tunnel is sandy soil, wr=30%, d s =0.03m, shield machine R=0.5m, B=0.02m, tool w=0.08m, ct=0.01m, θ 1 = 0, ρ 1 = 70mm.

[0183] According to formula (6), it is calculated that θ≥13.586°, and the corresponding c max for 26.

[0184] to c max =26 checks: according to formula (1) and formula (2), c max = 26 hours r s =4.15×0.08=0.332m, R-B-r s =0.148m>l min =4.65×0.03=0.1395m, so c in step 4 max =26.

[0185] According to formula (7), s'=106mm.

[0186] According to formula (10), Then N s1 =6.

[0187] According to formula (11), N s =6.

[0188] According to formula (12),

[0189] According to step 4, when c max >N s hour,

[0190] According to formula (13), formula (14), formula (15) and step 4, table 3 is obtained.

[0191] Table 3 The results of the cutter layout design of Example 1

[0192]

[0193]

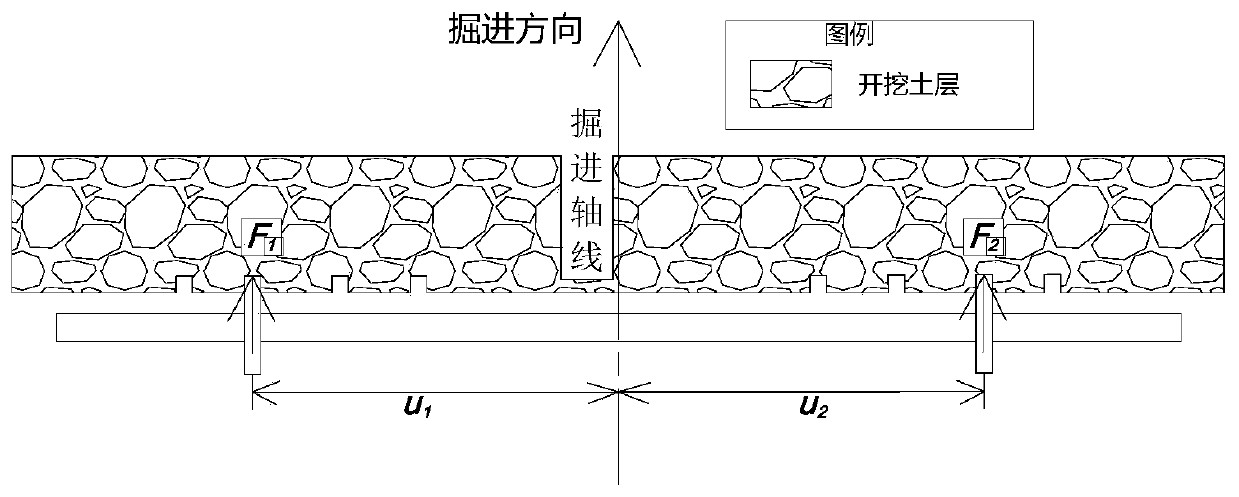

[0194] According to step 5, each tool satisfies formula (21), so the tool arrangement design is as follows Figure 10 sho...

Embodiment 2

[0196] The working face is moderately weathered tuff interbedded with pebble layers, R c =24MPa, d s =0.3m, shield machine R=1m, B=0.1m, cutter w=0.1m, ct=0.02m, θ 1 = 1, ρ 1 =80mm.

[0197] According to formula (6), it is calculated that θ≥31°, and the corresponding c max for 10.

[0198] to c max =10 to check: according to formula (1) and formula (2), c max = 10 o'clock r s =1.62×0.1=0.162m, R-B-r s =0.738m>l min =2.12×0.3=0.636m, so c in step 4 max =10.

[0199] According to formula (8), s'=92mm.

[0200] According to formula (10), Then N s1 =11.

[0201] According to formula (11), N s =12.

[0202] According to formula (12),

[0203] According to step 4, when c max s hour,

[0204] According to formula (16), formula (17), formula (18), formula (19), formula (20) and step 4, get Table 4.

[0205]The cutter layout design result of table 4 embodiment 2

[0206]

[0207]

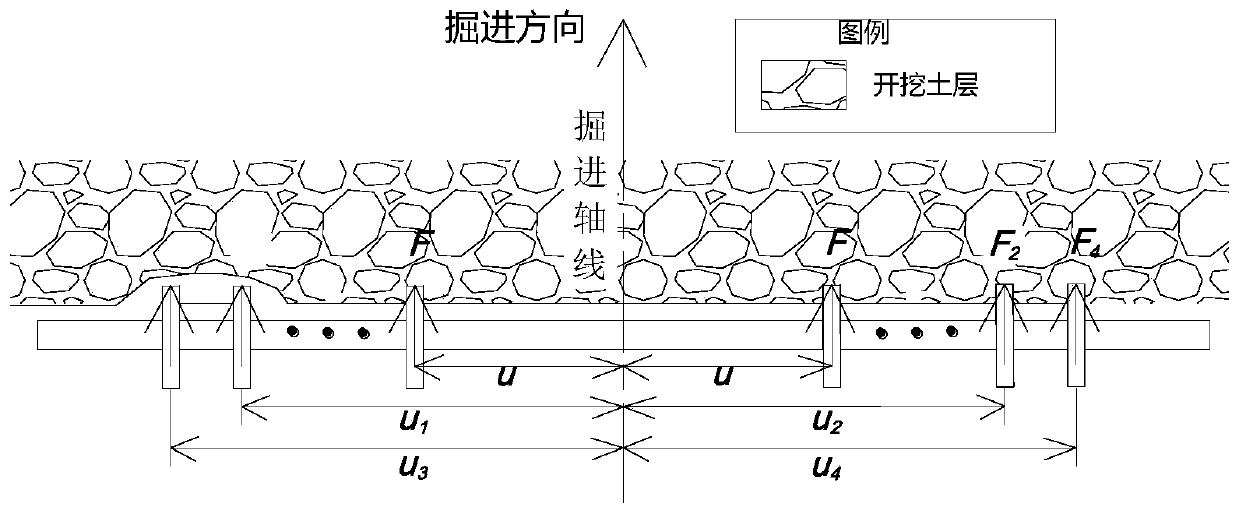

[0208] According to step 5, each tool satisfies formula (21), so the tool...

Embodiment 3

[0210] The face of the face is moderately weathered granite layer, R c =60MPa, d s =0.12m, shield machine R=0.3m, B=0.05m, tool w=0.12m, ct=0.02m, θ 1 = 0, ρ 1 = 60mm.

[0211] According to formula (6), it is calculated that θ≥78.34°, and the corresponding c max for 4.

[0212] to c max =4 is checked: according to formula (1) and formula (2), c max = 4 o'clock r s =0.71×0.12=0.0852m, R-B-r s =0.1648m>l min =1.21×0.12=0.1452m, so c in step 4 max =4.

[0213] According to formula (9), s'≈84.5mm.

[0214] According to formula (10), Then N s1 =4.

[0215] According to formula (11), N s =4.

[0216] According to formula (12),

[0217] According to step 4, when c max =N s hour,

[0218] According to formula (13), formula (14), formula (15) and step 4, table 5 is obtained.

[0219] Table 5 The results of the cutter arrangement design of the third embodiment

[0220]

[0221] According to step 5, each tool satisfies formula (21), so the tool arrangement d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com