Chemically amplified resist composition and patterning process

一种化学增幅、抗蚀剂的技术,应用在光学、图纹面的照相制版工艺、用于光机械设备的光敏材料等方向,能够解决感光度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0282] Examples of the invention are given below by way of illustration and not by way of limitation. The abbreviation "pbw" means parts by weight.

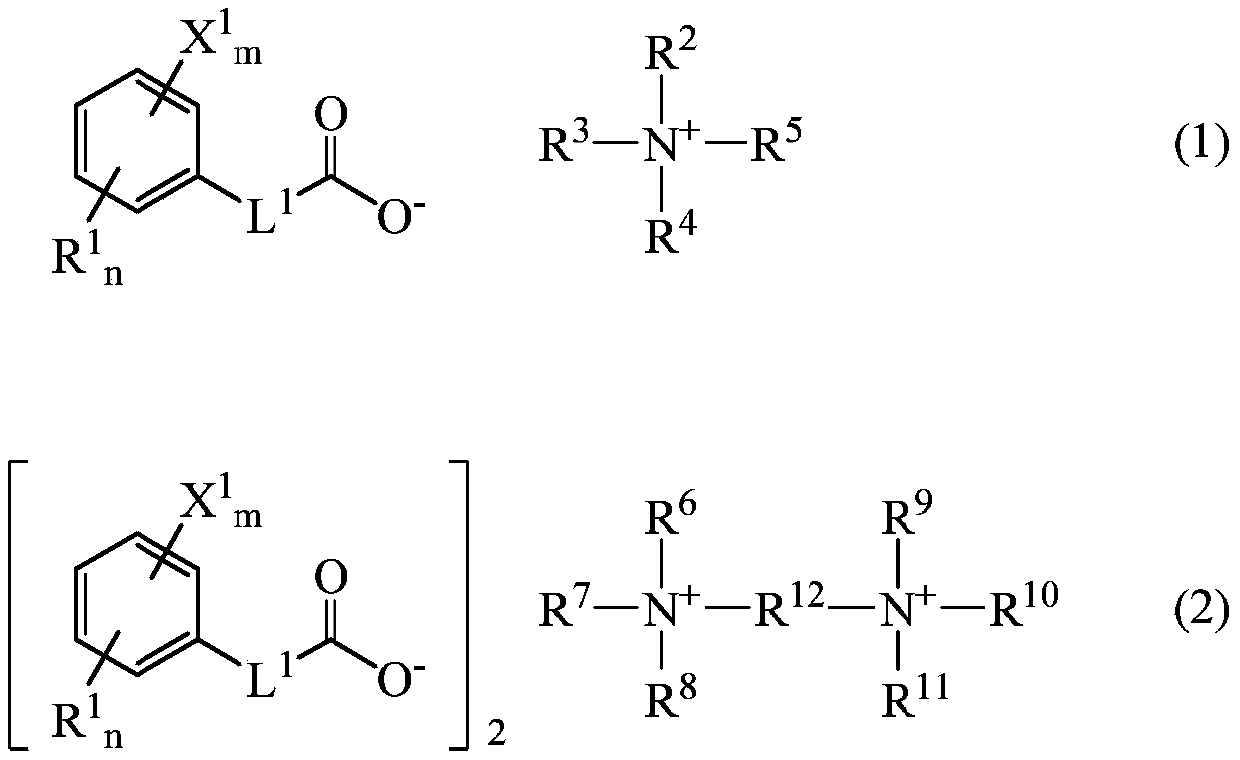

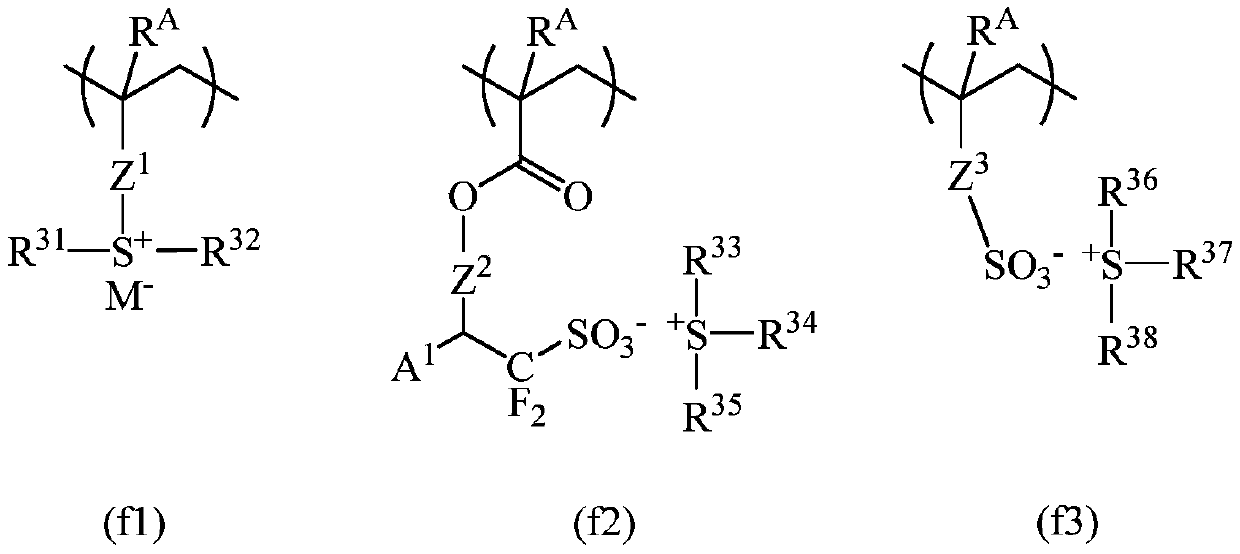

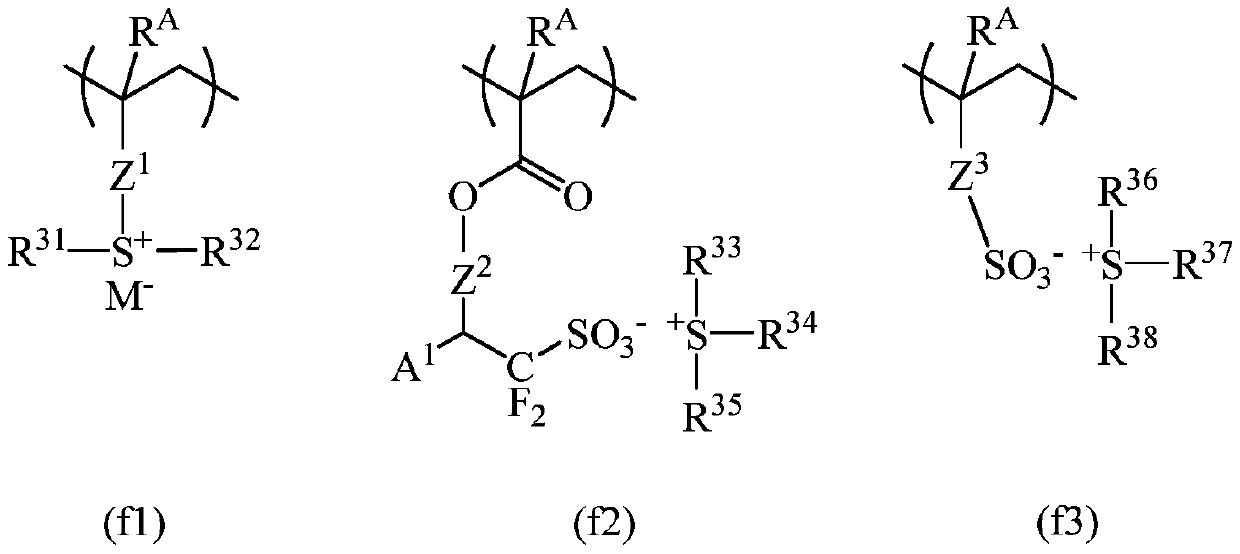

[0283] Quencher 1-22, amine compound 1, and carboxylic acid 1 used in the resist composition have the structures shown below. Quenchers 1-22 were prepared by neutralization of ammonium hydroxide or amine compounds providing the cations shown below with carboxylic acids bearing iodo or bromo aromatic rings providing the anions shown below.

[0284]

[0285]

Synthetic example

[0287] Synthesis of base polymers (polymers 1-3)

[0288] The base polymer was prepared by combining appropriate monomers, performing their copolymerization reaction in a tetrahydrofuran (THF) solvent, pouring the reaction solution into methanol to crystallize, repeatedly washing with hexane, separating and drying. For the resulting polymers denoted polymers 1-3, using 1 Composition was analyzed by H-NMR spectroscopy, and Mw and Mw / Mn were analyzed by GPC using THF solvent relative to polystyrene standards.

[0289]

Embodiment 1-27 and comparative example 1-7

[0291] Preparation of resist composition

[0292] A resist composition was prepared by dissolving each component in a solvent according to the formulation described in Tables 1-3, and filtering through a filter having a pore size of 0.2 μm. The solvent contained 100 ppm of surfactant FC-4430 (3M). The components in Tables 1-3 are shown below.

[0293] Base polymer: Polymer 1-3 of the above formula

[0294] Organic solvents:

[0295] PGMEA (Propylene Glycol Monomethyl Ether Acetate)

[0296] CyH(cyclohexanone)

[0297] PGME (Propylene Glycol Monomethyl Ether)

[0298] Acid generator: PAG 1 to PAG 4 of the following structural formula

[0299]

[0300] Comparing Quenchers 1-5:

[0301]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com