Life assessment method of atmospheric corrosion of low-alloy corrosion-resistant steel

A technology for atmospheric corrosion and life assessment, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve difficult material corrosion life evaluation and prediction, lack of simulation effect of marine atmospheric environment, and lack of dry-wet alternation and other issues to achieve the effect of low cost, high reliability and high correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for evaluating the corrosion life of low-alloy corrosion-resistant steel in a marine atmospheric environment, including the following steps:

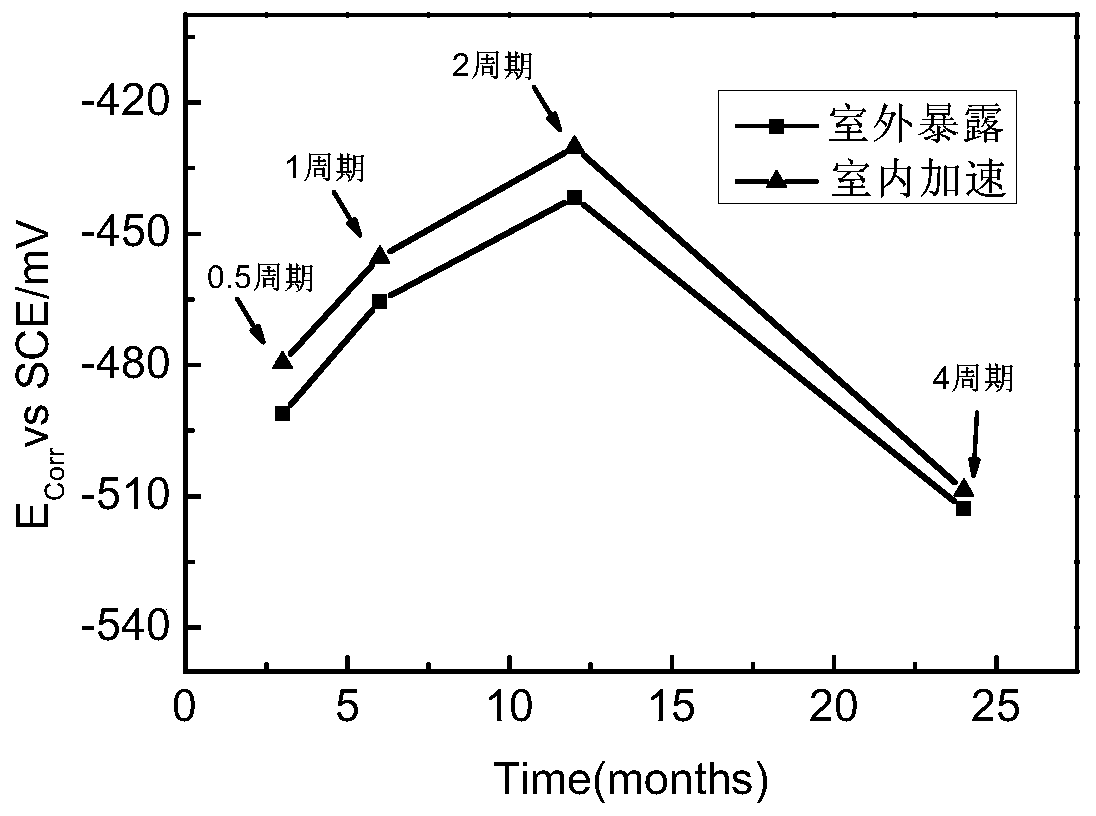

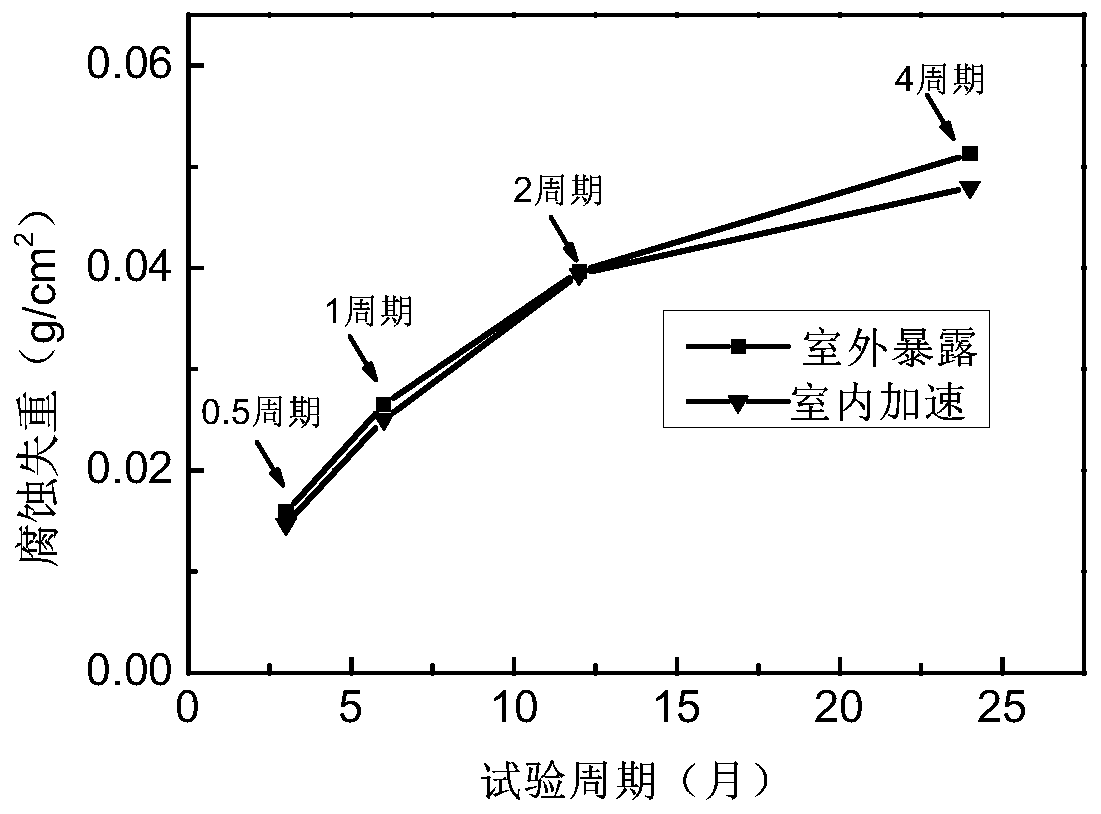

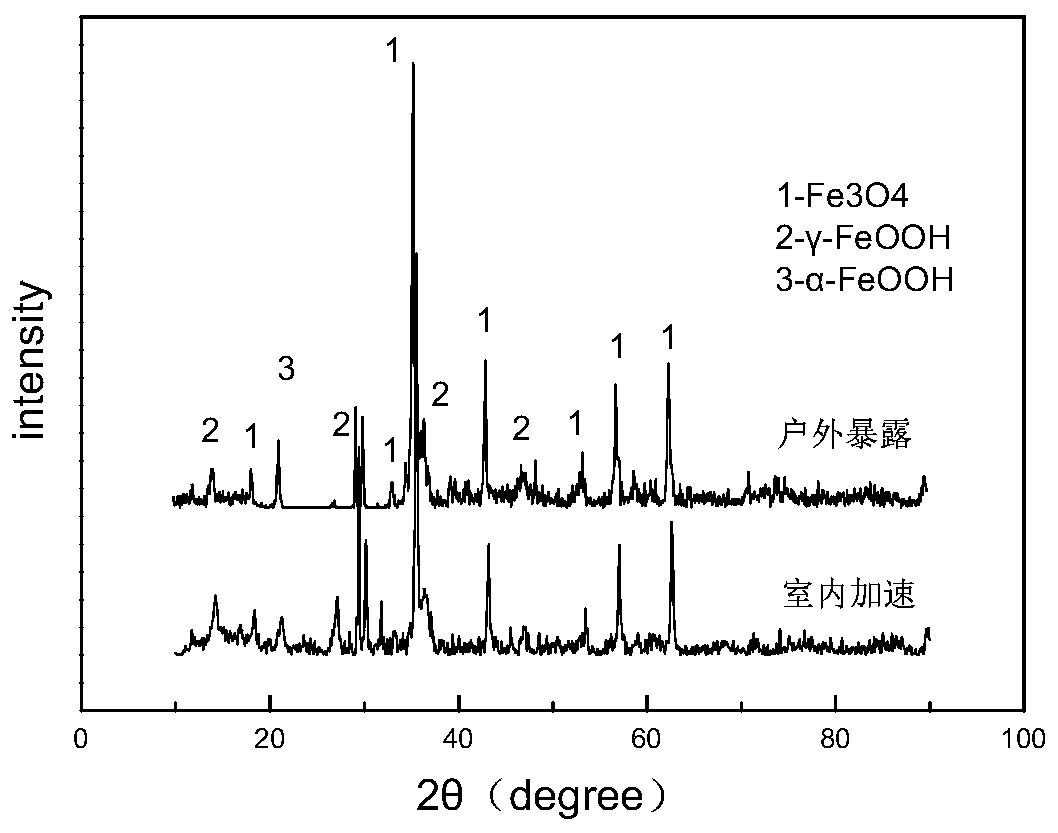

[0035] Step 1: The natural environment exposure corrosion test samples and indoor accelerated corrosion test samples are made of the same low-alloy steel material. According to GB / T 25834-2010, the outdoor air exposure test was carried out, the test site was Sanya City, the test time was two years, and the test period was 3, 6, 12 and 24 months.

[0036] Step 2: Indoor accelerated corrosion samples are carried out in a laboratory simulation environment. The laboratory accelerated corrosion test solution uses 3.5% NaCl+0.01mol / L NaHSO3+0.01mol / L HNO3, the test temperature is 40±2°C, the RH is 90%, the continuous salt spray time is 20min, and the immersion and drying times are respectively 20min and 80min, with 120min as a cycle, 36 cycles constitute an acceleration cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com