Process method for brewing multiple-flavor liquor by solid state fermentation in pottery jar

A solid-state fermentation, compound aroma technology, applied in microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc. problems, to achieve the effect of ensuring yield and quality, ensuring quality, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

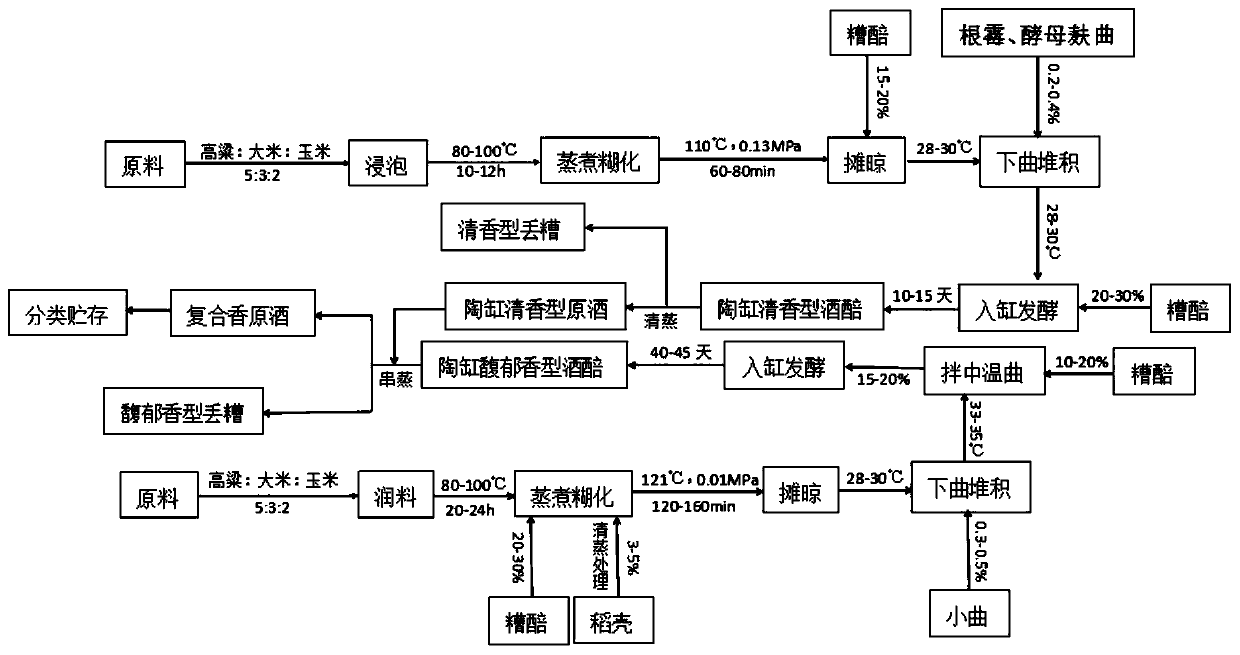

Method used

Image

Examples

Embodiment 1

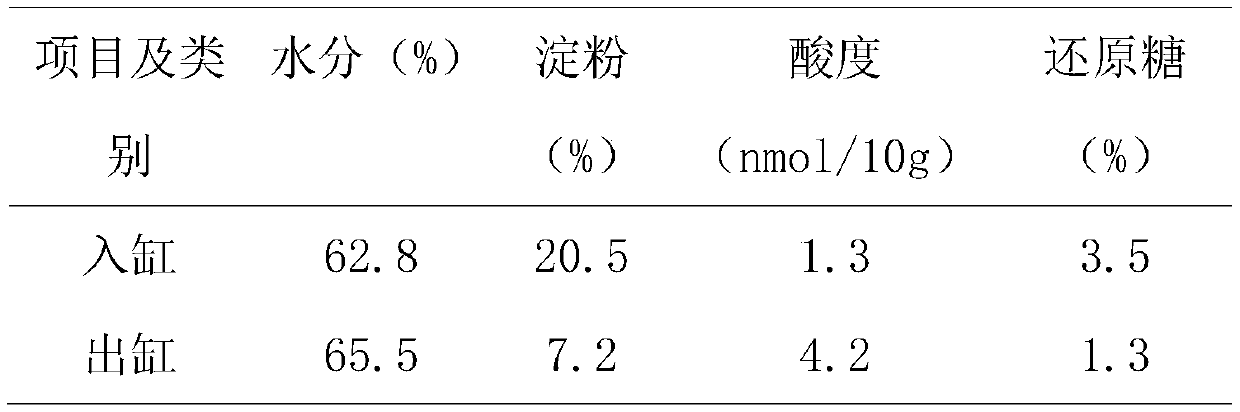

[0022] Take sorghum and crush it into a five-petal plum blossom shape, remove the germ of corn, mix and mix well, soak in hot water at about 85°C for 12 hours, add rice and mix well, put it in a steamer with pressure and cook for 60 minutes at a temperature of 110°C. The pressure is 0.13 MPa; the cooked grain unstrained spirits is mixed with 20% of the total mass of raw grain grains, spread in the air and cooled to 28-30°C, mixed with 0.3% of the total mass of raw grains with pure rhizopus koji and yeast bran koji, and placed in the stack The saccharification bed was 30°C, and the stacking saccharification was carried out for 24 hours.

[0023] Stack the saccharified grain unstrained spirits, add grain unstrained spirits with 26% of the total mass of the raw grain and supplement the slurry water to 63%, put them into the fermentation vat in layers, control the temperature of the vat at about 21°C, and step on the cellar while the grain unstrained spirits enter the cellar. The ...

Embodiment 2

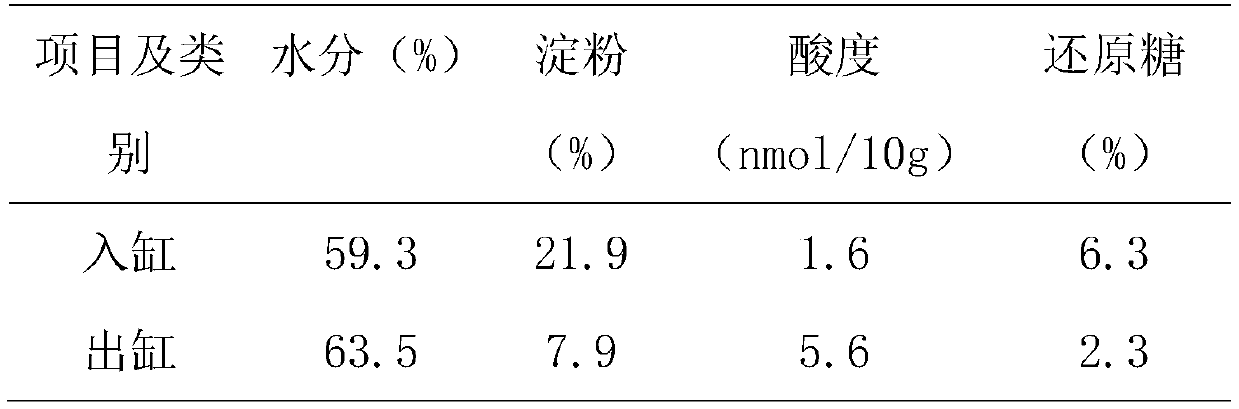

[0028] Take sorghum and crush it into a five-petal plum blossom shape, remove the germ of corn, mix well, add hot water at 85°C and mix evenly, no clear water seeps out, moisten the material for 24 hours, mix in rice, 25% of the total mass of raw grain grains, 5% of the total mass of the raw grains, steamed rice husks, etc., mixed well, steamed in a retort for 140 minutes at a temperature of 121°C, and a pressure of 0.01MPa. After the small koji is uniform, put it in the stacking mash bed at 33°C and stack it for 24 hours. After stacking and saccharifying the fragrant-flavored grain unstrained spirits, mix it with 20% of the total mass of raw grain medium-temperature Daqu, add 15% of the total mass of raw grain grains and mix. Supplementary slurry water up to 60%.

[0029] First lay a 10cm thick pit mud on the bottom of the pottery vat, and then put the grain unstrained spirits that have been spread out and added koji into the fermentation vat in layers. The temperature of ent...

Embodiment 3

[0034] According to embodiment 1, obtain the original wine of pottery vat fragrance type, according to embodiment 2, obtain the fermented grains of pottery vat, rich and fragrant type. The cellar is relatively small, so the upper wine grains of the four pottery vats are distilled together, and the lower wine grains are distilled together). Pour the fragrance-flavored original wine into the bottom of the retort pot, steam and distill the fragrant and fragrant solid-state fermented grains in the ceramic jar, pick the wine in sections, and store it in grades to obtain the solid-state fermented compound-flavored original wine. The bad grains are used as bad grains to participate in the blending operation of the fragrant and fragrant grain grains.

[0035] Table 3 Chromatographic analysis and total acid statistics of compound fragrant original wine

[0036]

[0037]

[0038] Note: A total of 1000kg of raw grain is put into each 4 ceramic vats, wine production unit (Kg), alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com