Method for continuous phase change extraction of ganoderma lucidum polysaccharide, and method for evaluating extraction process based on online conductivity.

A technology of Ganoderma lucidum polysaccharide and electrical conductivity, applied in solvent extraction, separation method, solid solvent extraction and other directions, can solve the problems of low time consumption and efficiency, and achieve the effects of low cost, shortened extraction time, broad application prospects and advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 A comparison between continuous phase change extraction of Ganoderma lucidum polysaccharides and hot water extraction of Ganoderma lucidum polysaccharides

[0053] 1. Continuous Phase Change Extraction Method of Ganoderma lucidum polysaccharide

[0054] (1) Dry the dried ganoderma lucidum in block form at a temperature of 55° C., control the moisture content at 10%, and pulverize it to 10 meshes (the sieve aperture is 2 mm), so as to obtain the ganoderma lucidum powder;

[0055] (2) Add 2000g of Ganoderma lucidum powder into a 20L extraction kettle, set the extraction temperature to 100°C, extraction pressure to 0.10MPa, extraction flow rate to 60L / h, inject pure water into the extraction kettle, and extract continuously for 240min;

[0056] (3) After the extraction is completed, the extract flows through the desorption kettle, the desorption temperature is set at 75°C, and the desorption pressure is -0.08MPa. The polysaccharide extract of Ganoderma lucidum is...

Embodiment 2

[0067] Example 2 Research on Continuous Phase Change Extraction of Ganoderma lucidum Polysaccharide Method

[0068] According to the characteristics of ganoderma lucidum raw materials, the present invention continuously analyzes and determines and adjusts the technological conditions. Follow the steps below:

[0069] (1) drying the dried ganoderma lucidum in block form at a temperature of 55° C., controlling the moisture content to 10%, and pulverizing it to an appropriate mesh size to obtain a ganoderma lucidum powder;

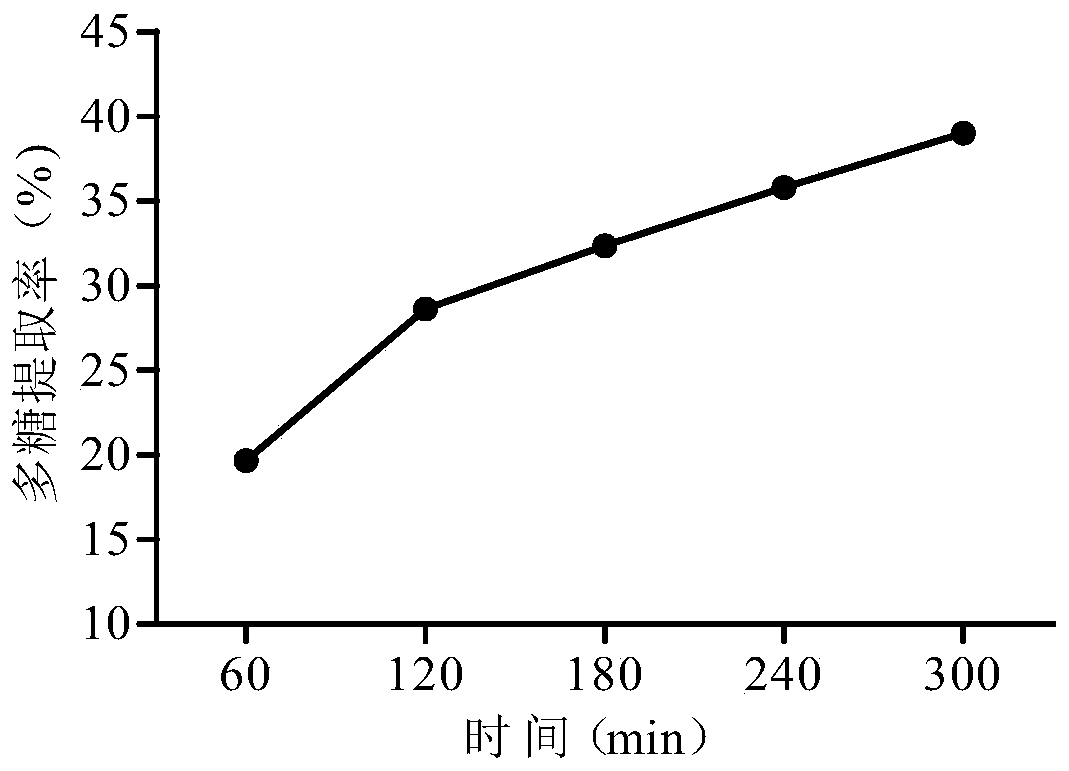

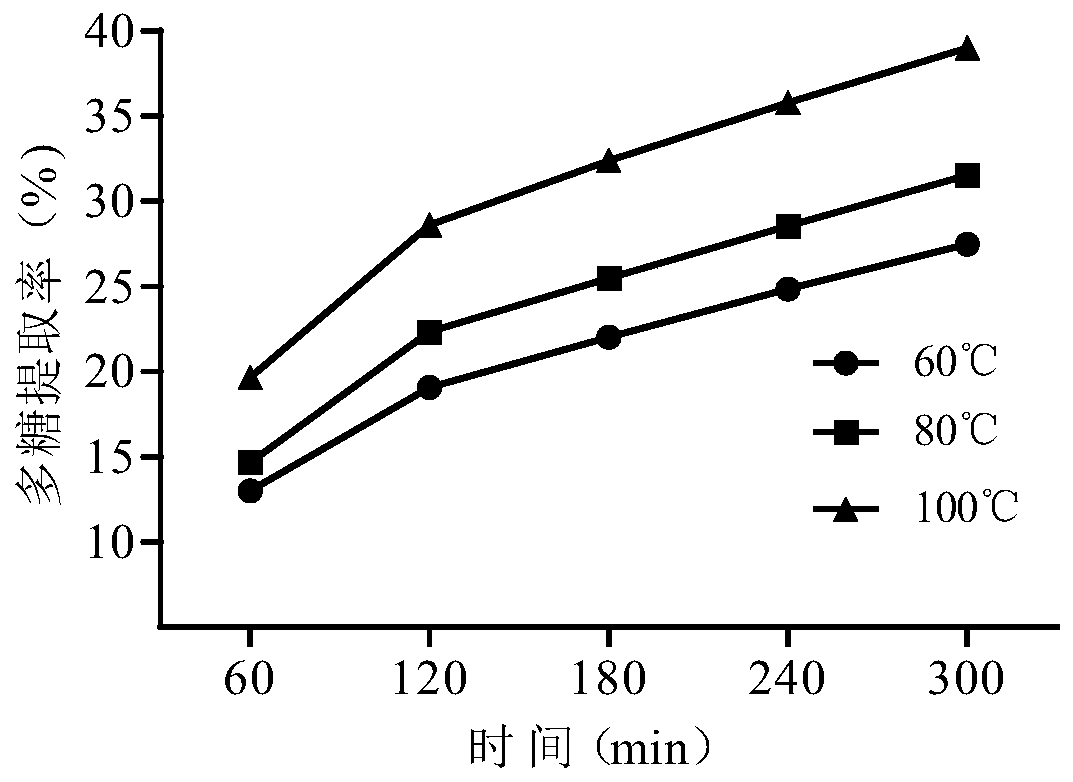

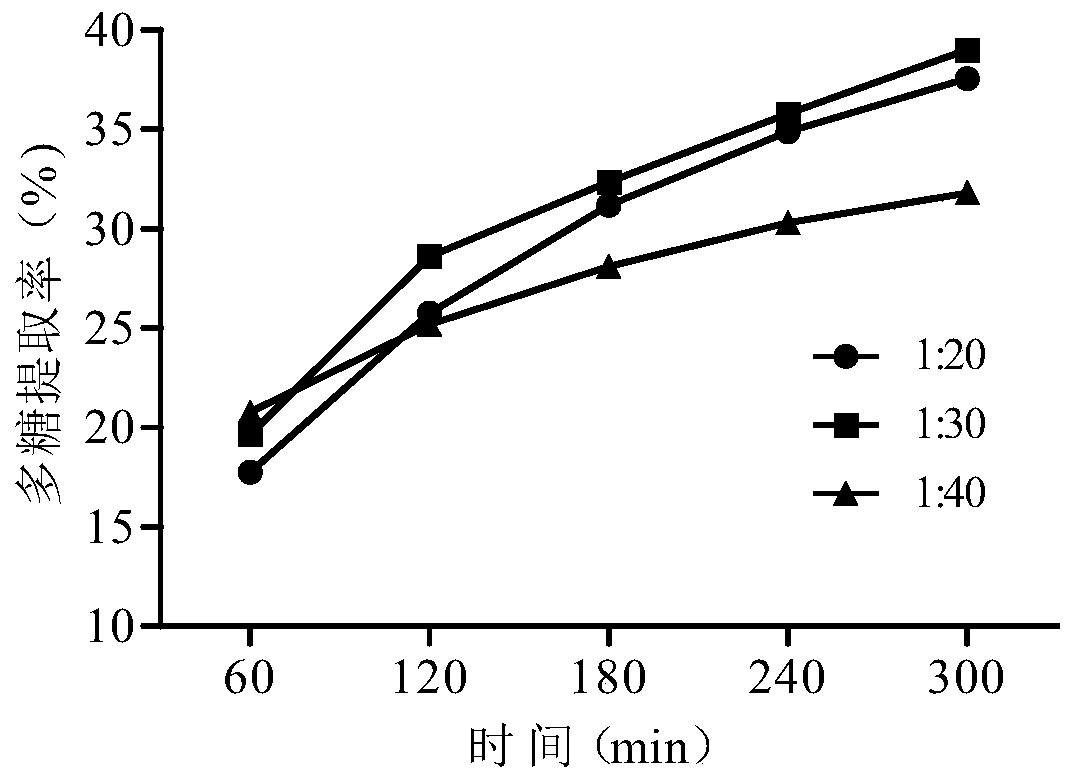

[0070] (2) Add an appropriate amount of Ganoderma lucidum powder into a 20L extraction kettle, determine the extraction pressure to be 0.10MPa, set the extraction temperature and extraction flow rate, inject pure water into the extraction kettle, and continue extracting for a certain period of time;

[0071] (3) After the extraction is completed, the extract flows through the desorption kettle, the desorption temperature is set at 75°C, and the desorption pr...

Embodiment 3

[0080] Embodiment 3 A kind of method of continuous phase change extraction Ganoderma lucidum polysaccharide

[0081] (1) Dry the dried ganoderma lucidum in block form at a temperature of 55° C., control the moisture content at 13%, and pulverize it to 20 mesh (the sieve aperture is 1 mm), so as to obtain the ganoderma lucidum powder;

[0082] (2) Add 2000g of Ganoderma lucidum powder into a 20L extraction kettle, set the extraction temperature at 80°C, pressure of 0.10MPa, and extraction flow rate of 40L / h, inject three-grade pure water with a pH of 7.0 into the extraction kettle, and extract continuously for 240min; control the Ganoderma lucidum powder The solid-liquid ratio with the extractant is 1:30g / mL;

[0083] (3) After the extraction is completed, the extract flows through the analysis kettle, the analysis temperature is set at 75°C, and the analysis pressure is 0.08MPa. After the extraction is completed, the Ganoderma lucidum polysaccharide extract is released in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com