Amorphous hollow carbon nanotube and preparation method thereof

A carbon nanotube and amorphous technology, which is applied in the field of amorphous hollow carbon nanotubes and its preparation, can solve the problems of poor battery cycle performance, safety hazards, volume changes, etc., and achieve simple manufacturing process, strong mechanical stability, and inhibition The effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

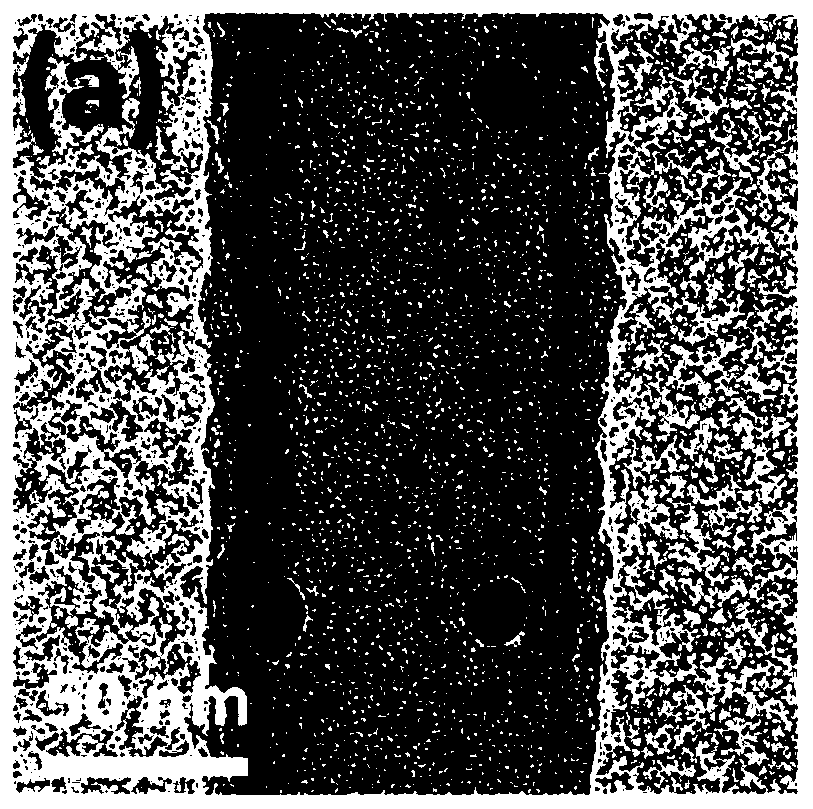

[0061] Amorphous hollow carbon nanotubes are prepared, and gold is used as an example to support particles. The experimental process is as follows: figure 1 As shown, using ZnO nanorods as templates, gold nanoparticles can be supported on them after further amino functionalization. On the basis of the above, the zinc oxide nanorods loaded with gold nanoparticles on the outer wall are coated with carbon. The carbonization process can convert the coating layer into amorphous carbon. After further etching the template, the target product can be obtained: hollow, inner wall Carbon tubes loaded with gold nanoparticles. Specific steps are as follows:

[0062] 1) Preparation of ZnO template: Dissolve 1g NaOH in 50mL ethanol to make solution A, dissolve 0.46g zinc acetate in 25mL ethanol to make solution B, add solution A to solution B, stir and ultrasonicate for 30 minutes, then introduce the resulting solution into 100mL reaction In a kettle, conduct a hydrothermal reaction at 150...

Embodiment 2

[0073] Nanoparticle-induced lithium metal achieves reversible and stable encapsulation in the inner cavity of amorphous carbon tubes. The whole deposition process can be divided into three steps: (1) lithiation: lithium ions move in one direction along the wall of the amorphous carbon tube under the action of an applied voltage, and fill in the pores and defects of the carbon tube; (2) Nanoparticle guidance: When lithium ions arrive at the site with nanoparticles, the nanoparticles are lithiated; (3) Lithium metal deposition: Lithium ions preferentially reach the surface of the lithiated nanoparticles and deposit stably in the inner cavity of the carbon tube.

[0074] The process of metal lithium deposition and stripping was observed by transmission electron microscopy, and the results are shown in image 3 . image 3 It is a process of in-situ deposition and exfoliation of lithium metal in carbon tubes loaded with gold particles. (a) and (c) are the first and second real-ti...

Embodiment 3

[0090] Nanoparticles induce Na metal to achieve reversible and stable encapsulation in the inner cavity of amorphous carbon tubes. The entire deposition process can be divided into three steps: (1) Sodiumization: Na ions move in one direction along the wall of the amorphous carbon tube under the action of an applied voltage, and fill in the pores and defects of the carbon tube; (2) Nanoparticle guidance: When sodium ions reach the site with nanoparticles, the nanoparticles are sodated; (3) Na metal deposition: Na ions preferentially reach the surface of the lithiated nanoparticles and deposit stably in the inner cavity of the carbon tube.

[0091] The process of metal sodium deposition and stripping was observed by transmission electron microscopy, and the results are shown in Figure 4 .

[0092] Figure 4 It is a process of in-situ deposition and exfoliation of sodium metal in carbon tubes loaded with gold particles. The two ends of the carbon tube are in contact with cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com