An adaptive variable inclination multi-drum current receiving device for electric locomotives

A technology for electric locomotives and current receiving devices, which is applied in the field of rail transportation, and can solve the problems of carbon slides falling off, restricting the speed of trains, and increasing Joule heat, so as to reduce the probability of arcing and ensure stable current receiving The effect of reducing the contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

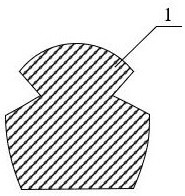

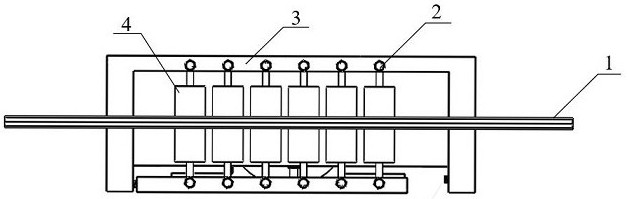

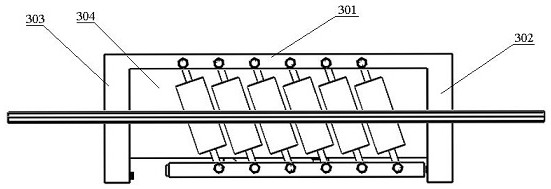

[0035] Such as Figure 1-9 As shown, an adaptive variable inclination angle multi-drum current receiving device for electric locomotives includes a plurality of metal drums 4 and a drum base 3 for placing the metal drums 4; the drum base 3 is a box-shaped structure, including a rectangular bottom plate 304. The side plate 301 connected to the long side of the bottom plate 304 and the first top plate 303 and the second top plate 302 respectively connected to the short side of the bottom plate 304 are arranged on the bottom plate 304; a movable plate 7 arranged opposite to the side plate 301 is also included; Both the side plate 301 and the movable plate 7 are provided with square holes one-to-one corresponding to the metal drum 4; one end of the drum rotating shaft 10 of the metal drum 4 is embedded in the square hole of the side plate 301, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com