Mixing and grinding integrated machine for watercolor for drawing

A watercolor paint and integrated machine technology, applied in painting tools, decorative art, grain processing, etc., can solve the problems of increased labor intensity of operators, low production efficiency, inconvenient continuous production and processing of watercolor paint, etc., to improve the grinding effect, The effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

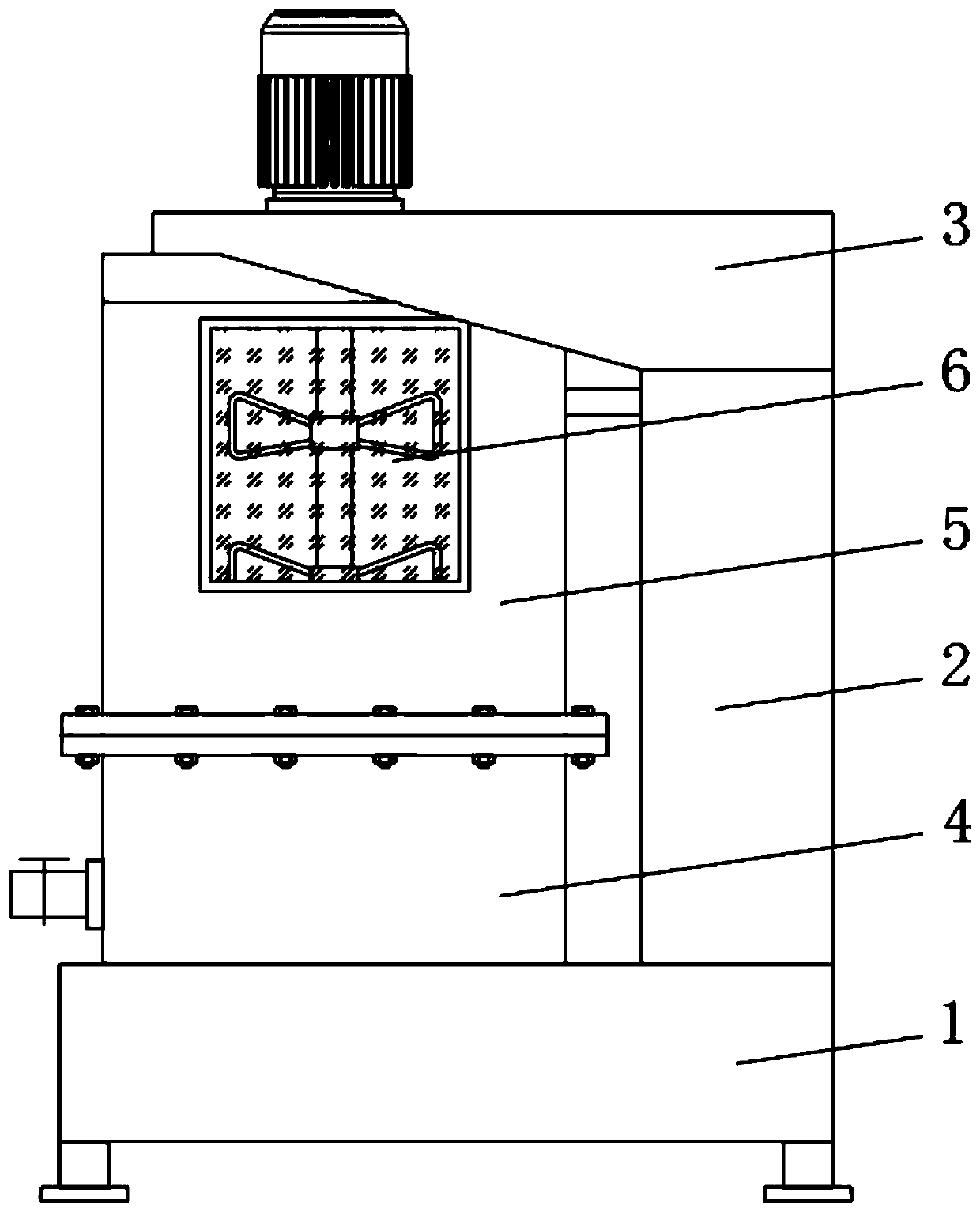

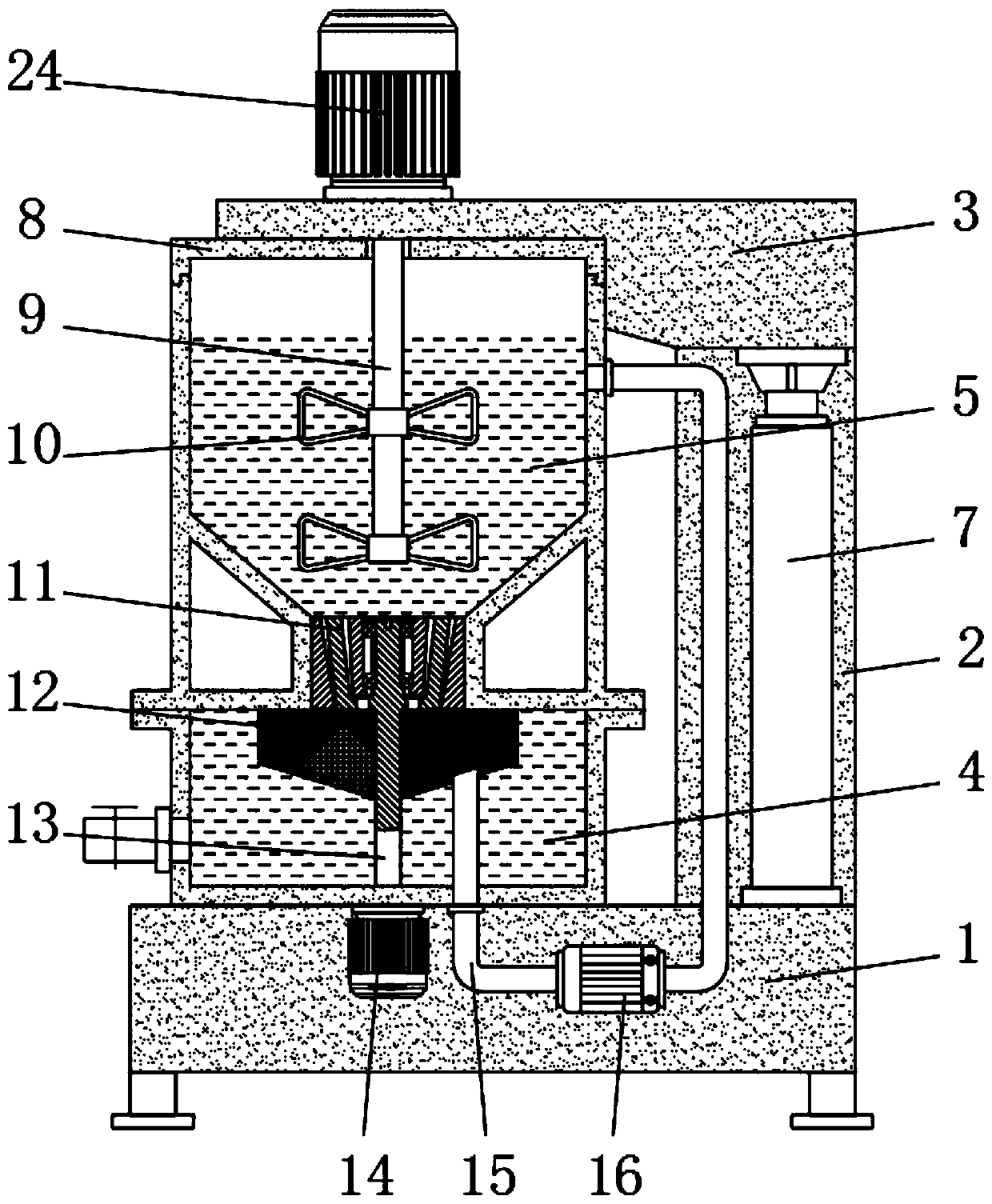

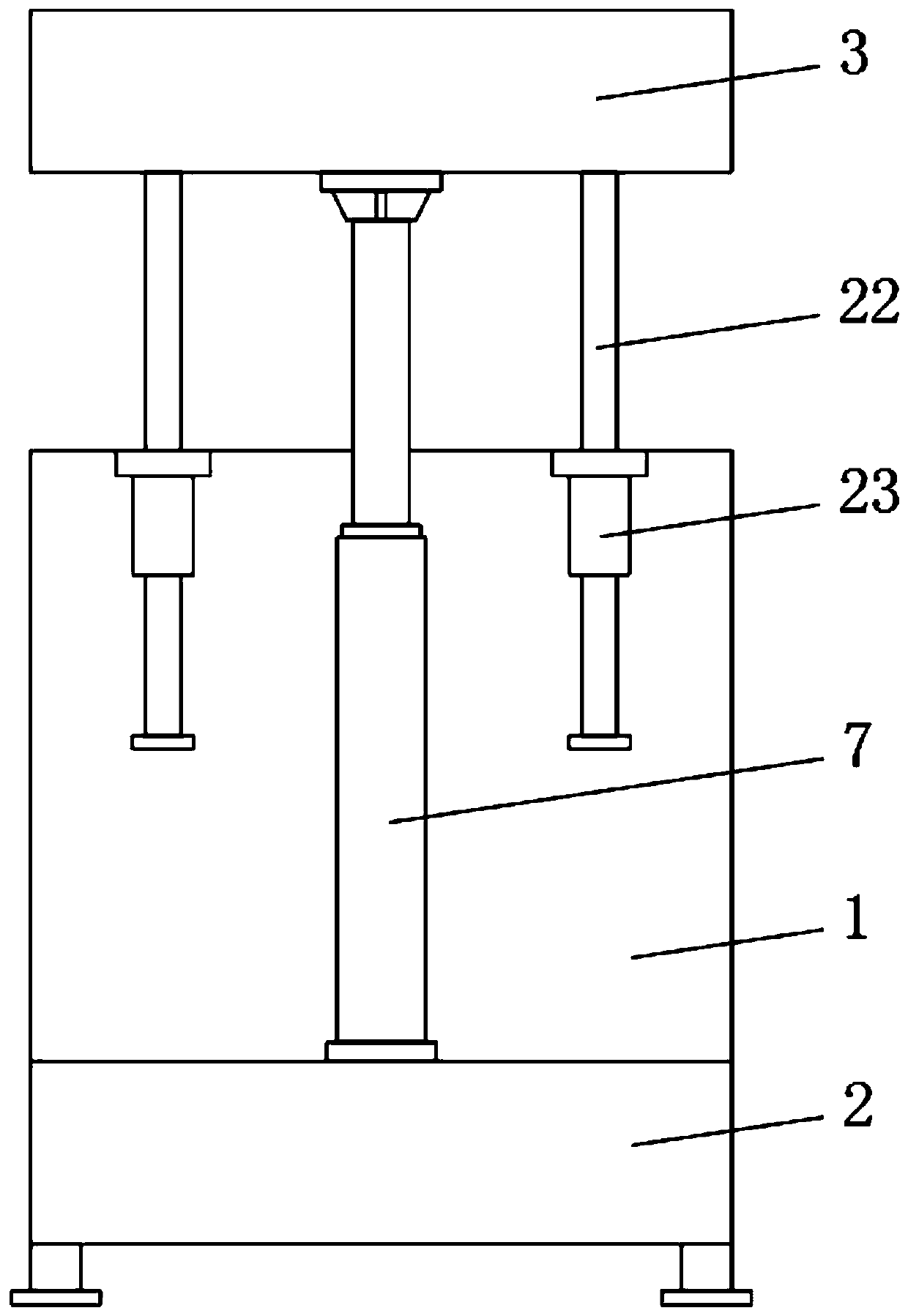

[0034] Embodiment one, with reference to Figure 1-2 with Figure 7 , an all-in-one machine for mixing and grinding watercolor pigments for painting, comprising a base 1, a side frame body 2 and a cantilever 3, the side frame body 2 is fixed on one side of the top surface of the base 1, and a cantilever 3 is connected to the top of the side frame body 2, and the cantilever 3 and the base 1 are vertically provided with a stirring chamber 5 and a grinding chamber 4 from top to bottom, and the stirring chamber 5 and the grinding chamber 4 are fixedly connected by bolts, and a stirring motor 24 is installed on the top surface of the cantilever 3, and the stirring motor 24 outputs The shaft is connected to the stirring paddle 9 inside the stirring chamber 5, and the lower end of the stirring paddle 9 is welded with a paddle rod 10, a grinding assembly 11 is arranged below the stirring paddle 9, and a filter hopper 12 is arranged below the grinding assembly 11, and the filter hopper...

Embodiment 2

[0035] Embodiment two, refer to figure 1 with image 3 , the grinding assembly 11 includes a grinding rod 13, a grinding motor 14, a fixed grinding cylinder 17, a power grinding cylinder 18, an unpowered cylinder 19, an end cover 20, and a spacer 21, wherein the power grinding cylinder 18 is a "cup"-shaped structure, and Fixed on the grinding rod 13, the non-powered cylinder 19 is rotatably connected with the grinding rod 13 through bearings, and a spacer 21 for fixing the bearing is set on the grinding rod 13, and an end cover 20 is installed on the upper end of the grinding rod 13, and the side of the power grinding cylinder 18 and the bottom surface are respectively evenly provided with a plurality of first transition holes 18.1 and a plurality of second transition holes 18.2. When the grinding motor 14 drives the power grinding cylinder 18 on the grinding rod 13 to rotate at a high speed, the outside and inside of the power grinding cylinder 18 are respectively connected w...

Embodiment 3

[0036] Embodiment three, refer to Figure 4-6One side of the grinding motor 14 is located inside the base 1 with a conveying pipe 15 and a circulating pump 16, and the circulating pump 16 is installed on the conveying pipe 15, one end of the conveying pipe 15 is connected to the filter bucket 12, and the other end is connected to the stirring tank through the side frame body 2. The bin 5 is connected, and the ground watercolor paint is sieved into the grinding bin 4 through the filter bin 12, and then the pigment inside the filter bin 12 is transported to the mixing bin 5 through the delivery pipe 15 and the circulation pump 16, and then mixed, stirred, and ground again. Processing, such cyclic processing of watercolor paints can ensure that the watercolor paints are fine, uniform, and free of particles, which solves the disadvantages of manual transfer of watercolor paints to a three-roll mill for repeated grinding

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com