Cigarette mark printing procedure color marking method and cigarette mark printing procedure color marking equipment

A printing equipment and process technology, applied in the field of color marking method of cigarette label printing process and its equipment, can solve the problems of waste of resources, waste of material cost, consumption of large labor force, etc., and achieve the reduction of waste of resources, the saving of social resources, and the convenience of Return the effect of the check

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

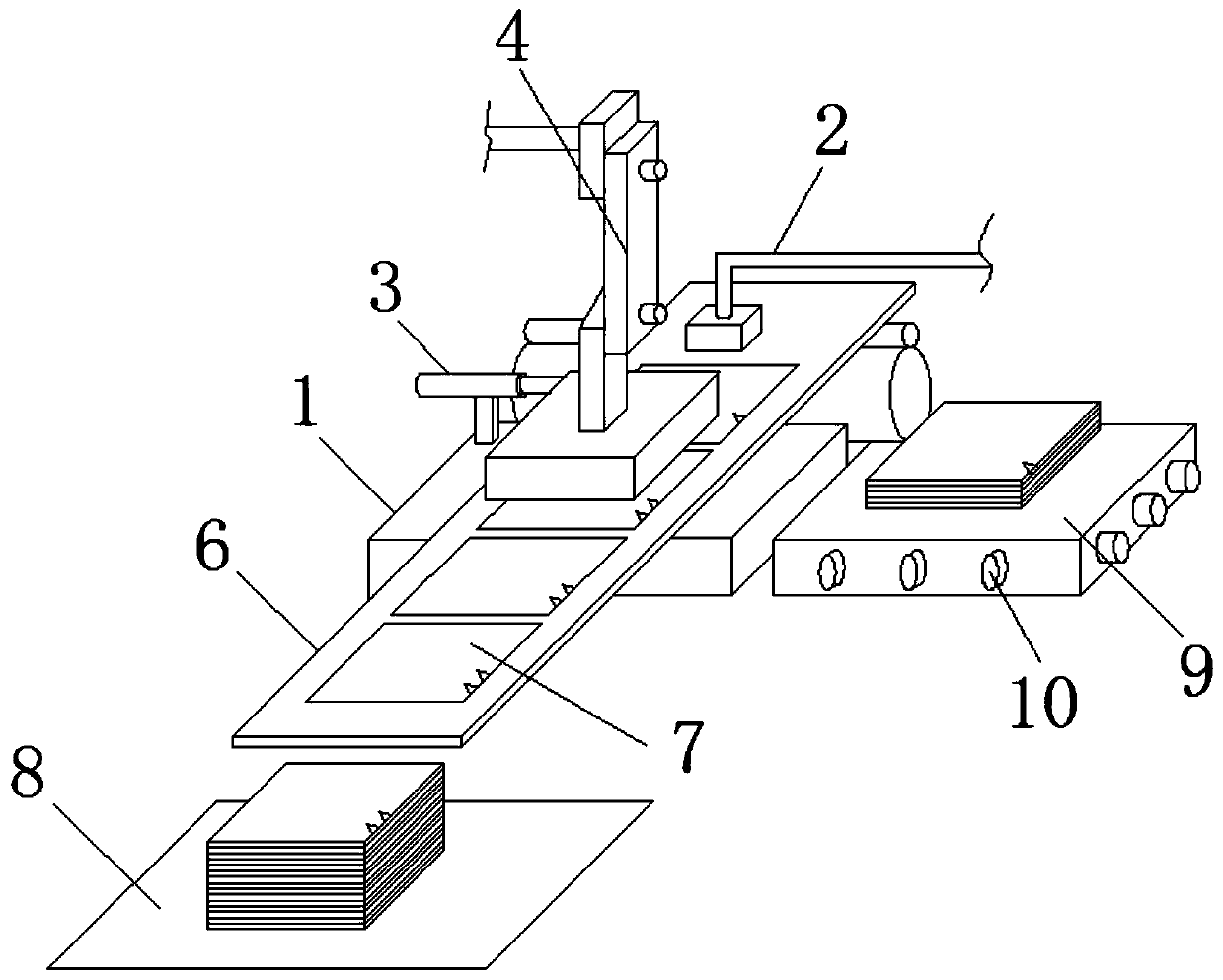

[0027] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0028] A method for marking the color of a cigarette label printing process, comprising the following steps: printing process modification→printing equipment modification→transport printing→printing process induction→screening and printing completion;

[0029] 1. Number and sort the processes of the printing process, so that the processes of the printing process are completed step by step;

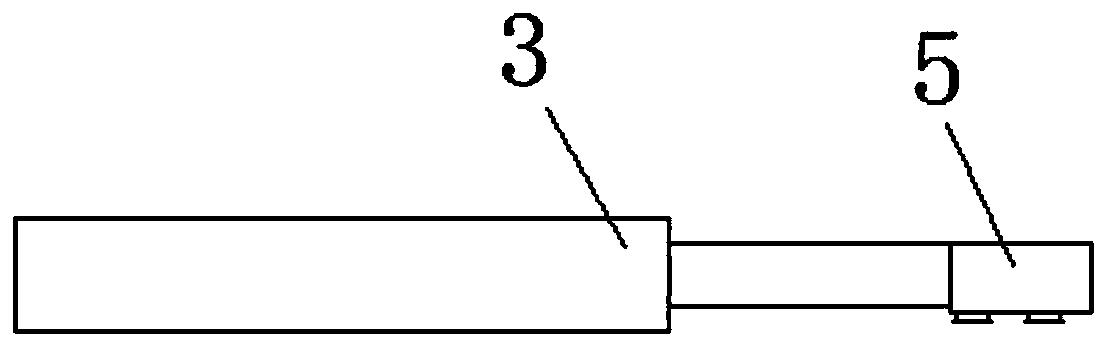

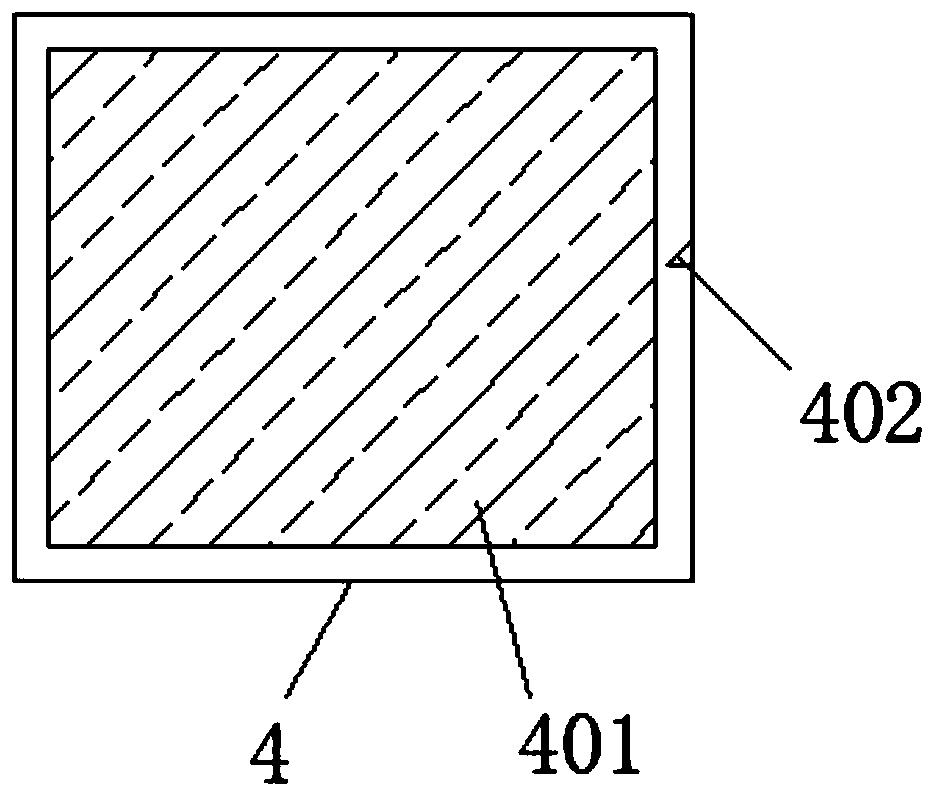

[0030] 2. Set dyeing blocks at the edge of printing equipment in each process, and install color mark sensors and electric telescopic rods on the travel route of printed products, and the movement of printed products uses plate-type conveying equipment for continuous print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com