Greenhouse support pipe production line

A production line and pipe technology, applied in the field of greenhouse support pipe production line, can solve the problems of low work efficiency, complicated process, complicated transfer, etc., and achieve the effects of reducing labor intensity, improving production efficiency, and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

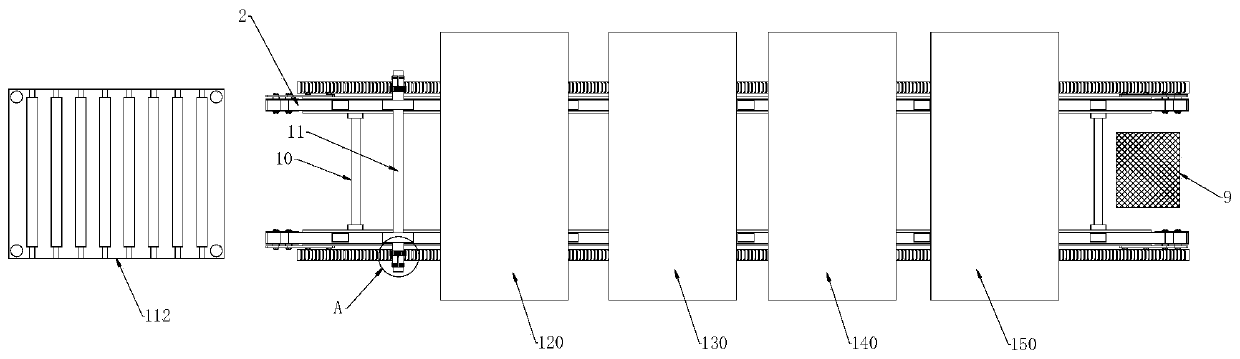

[0042] The production line of the greenhouse support pipe 11 of the present invention comprises a loading rack 110, a polishing machine 120, an intermediate frequency heating machine 130, a plastic wrapping machine 140, a cooling system 150, a polishing machine 120, an intermediate frequency heating machine 130, and a plastic wrapping machine arranged side by side in sequence 140 and the cooling system 150 are provided with a conveying device 2, the upper end of the conveying device 2 is provided with two sets of fixing seats 210 side by side, and the upper end of a set of fixing seats 210 is correspondingly provided with two sets of mounting seats 3, The mounting base 3 is provided with a through hole 310 for the pipe 11 to pass through, the pipe 11 is connected to the mounting base 3 in rotation, and the outside of the mounting base 3 is provided with a fastening unit 4 for driving the pipe 11 to rotate.

[0043] After adopting the above technical solution: the intermediate f...

Embodiment 2

[0045] This embodiment is further optimized on the basis of Embodiment 1 as follows: the fastening unit 4 includes a fixed cylinder 410, a collar 420 and a tooth plate 430; One end of the seat 210 is provided with a protruding ring 450, and the side wall of the fixed cylinder 410 is provided with a plurality of through grooves 440, one end of the through grooves 440 runs through the side away from the fixed seat 210, and the collar 420 is sleeved on the fixed cylinder 410. The outer wall of the collar 420 is provided with an annular tooth 421 , the tooth plate 430 is disposed at the lower end of the collar 420 , and the tooth plate 430 and the annular tooth 421 are engaged with each other. The inner diameter of the collar 420 is larger than the outer diameter of the fixing cylinder 410 , and the inner diameter of the collar 420 is smaller than the outer diameter of the protruding ring 450 .

[0046] After adopting the above technical solution: the fastening unit 4 drives the p...

Embodiment 3

[0048] This embodiment is further optimized on the basis of Embodiment 1 as follows: the conveying device 2 is a double-track conveying crawler belt, or a double-track conveying belt, and one group of fixed seats 210 are respectively arranged on two tracks of the conveying device 2, and the The device 2 is provided with multiple sets of fixing seats 210 , and gaps are provided between adjacent fixing seats 210 ; the lower end of the mounting seat 3 is provided with a slider 320 , and the upper end of the fixing seat 210 is provided with a chute that is compatible with the slider 320 . The slider 320 is a dovetail block or a T-shaped block, and the chute is a dovetail groove or a dovetail block adapted to the slider 320 .

[0049] After adopting the above technical scheme: the conveying device 2 is a double-track conveying crawler belt, so that the fixed seat 210 and the mounting seat 3 that are installed in cooperation are respectively located on the two tracks, and there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com