Hollow cylindrical garbage microwave pyrolysis furnace

A hollow cylinder, cracking furnace technology, applied in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of reduced applicable value, high garbage cost, small reduction, etc., to improve the utilization rate. , the volume expansion, the effect of increasing the amount of garbage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

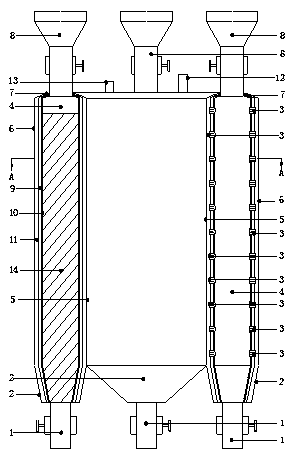

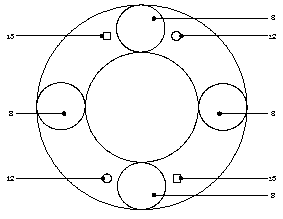

[0023] 1. in figure 1 The hollow cylindrical waste microwave pyrolysis furnace shown in is composed of a bin cover (7), a bin body (4), a discharge port (2), a feeder (8), a discharger (1), a cracking gas outlet pipe (12) and safety valve (13), its shape is a hollow cylinder, and vertically arranged with the ground.

[0024] 2. figure 1 The bin cover (7) of the hollow cylinder garbage microwave pyrolysis furnace shown in is located on the top of the bin body (4) and is in the shape of a ring, and the bin cover (7) is provided with a feeder (8), cracking Gas outlet pipe (12) and safety valve (13).

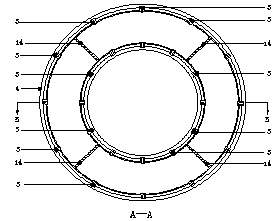

[0025] 3. figure 1 The bin body (4) of the hollow cylindrical waste microwave cracking furnace shown in , is located in the central area of the hollow cylindrical waste microwave cracking furnace, and is in the shape of a hollow cylinder and is perpendicular to the ground; layer (10), heat insulation layer (9) and protective layer (11), and several microwave inlets (3) are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com